Abstract

We adopt thick-film technology to produce ultra high vacuum compatible interfaces for electrical signals. These interfaces permit voltages of hundreds of volts and currents of several amperes and allow for very compact vacuum setups, useful in quantum optics in general, and in particular for quantum information science using miniaturized traps for ions (Kielpinski et al. in Nature 417:709, 2002) or neutral atoms (Folman et al. in Phys. Rev. Lett. 84:4749, 2000; Treutlein et al. in Fortschr. Phys. 54:702, 2006; Hofferberth et al. in Nat. Phys. 2:710, 2006). Such printed circuits can also be useful as pure in-vacuum devices. We demonstrate a specific interface which provides 11 current feedthroughs, more than 70 dc feedthroughs and a feedthrough for radio frequencies. We achieve a pressure in the low 10-11 mbar range and demonstrate the full functionality of the interface by trapping chains of cold ytterbium ions, which requires the presence of all of the above mentioned signals. In order to supply precise time-dependent voltages to the ion trap, a versatile multi-channel device has been developed.

Similar content being viewed by others

References

D. Kielpinski, C. Monroe, D.J. Wineland, Nature 417, 709 (2002)

R. Folman, P. Krüger, D. Cassettari, B. Hessmo, T. Maier, J. Schmiedmayer, Phys. Rev. Lett. 84, 4749 (2000)

P. Treutlein, T. Steinmetz, Y. Colombe, B. Lev, P. Hommelhoff, J. Reichel, M. Greiner, O. Mandel, A. Widera, T. Rom, I. Bloch, T.W. Hänsch, Fortschr. Phys. 54, 702 (2006)

S. Hofferberth, I. Lesanovsky, B. Fischer, J. Verdu, J. Schmiedmayer, Nat. Phys. 2, 710 (2006)

M.A. Rowe, A. Ben-Kish, B. Demarco, D. Leibfried, V. Meyer, J. Beall, J. Britton, J. Hughes, W.M. Itano, B. Jelenkovic, C. Langer, T. Rosenband, D.J. Wineland, Quantum Inf. Comput. 2, 257 (2002)

D. Stick, W.K. Hensinger, S. Olmschenk, M.J. Madsen, K. Schwab, C. Monroe, Nat. Phys. 2, 36 (2006)

S. Schulz, U. Poschinger, F. Ziesel, F. Schmidt-Kaler, New J. Phys. 10 (2008)

M. Harlander, R. Lechner, M. Brownnutt, R. Blatt, W. Hänsel, Nature 471, 200 (2011)

C.E. Pearson, D.R. Leibrandt, W.S. Bakr, W.J. Mallard, K.R. Brown, I.L. Chuang, Phys. Rev. A 73, 032307 (2006)

D.T.C. Allcock, J.A. Sherman, D.N. Stacey, A.H. Burrell, M.J. Curtis, G. Imreh, N.M. Linke, D.J. Szwer, S.C. Webster, A.M. Steane, D.M. Lucas, New J. Phys. 12, 053026 (2010)

D.L. Moehring, C. Highstrete, D. Stick, K.M. Fortier, R. Haltli, C. Tigges, M.G. Blain, New J. Phys. 13, 075018 (2011)

J.J. McLoughlin, A.H. Nizamani, J.D. Siverns, R.C. Sterling, M.D. Hughes, B. Lekitsch, B. Stein, S. Weidt, W.K. Hensinger, Phys. Rev. A 83, 013406 (2011)

M. Brownnutt, G. Wilpers, P. Gill, R.C. Thompson, A.G. Sinclair, New J. Phys. 8, 232 (2006)

M.D. Hughes, B. Lekitsch, J.A. Broersma, W.K. Hensinger, Cont. Phys. 52 (2011). doi:10.1080/00107514.2011.601918

W.S. Bakr, A. Peng, M.E. Tai, R. Ma, J. Simon, J.I. Gillen, S. Fölling, L. Pollet, M. Greiner, Science 329, 547 (2010)

C. Weitenberg, M. Endres, J.F. Sherson, M. Cheneau, P. Schauss, T. Fukuhara, I. Bloch, S. Kuhr, Nature 471, 319 (2011)

P. Böhi, M.F. Riedel, T.W. Hänsch, P. Treutlein, Appl. Phys. Lett. 97 (2010). doi:10.1063/1.3470591

T. Karin, I. Le Bras, A. Kehlberger, K. Singer, N. Daniilidis, H. Häffner, Appl. Phys. B 106, 117 (2011)

S. Schulz, U. Poschinger, K. Singer, F. Schmidt-Kaler, Fortschr. Phys. 54, 648 (2006)

F. Mintert, C. Wunderlich, Phys. Rev. Lett. 87, 257904 (2001)

F. Mintert, C. Wunderlich, Phys. Rev. Lett. 91, 029902 (2003)

C. Wunderlich, in Laser Physics at the Limits (Springer, Berlin, 2002), pp. 261–271

C. Wunderlich, C. Balzer, Adv. At. Mol. Opt. Phys. 49, 293 (2003)

C. Ospelkaus, C.E. Langer, J.M. Amini, K.R. Brown, D. Leibfried, D.J. Wineland, Phys. Rev. Lett. 101, 090502 (2008)

M. Johanning, A. Braun, N. Timoney, V. Elman, W. Neuhauser, C. Wunderlich, Phys. Rev. Lett. 102, 073004 (2009)

C. Ospelkaus, U. Warring, Y. Colombe, K.R. Brown, J.M. Amini, D. Leibfried, D.J. Wineland, Nature 476, 181 (2011)

K.R. Brown, A.C. Wilson, Y. Colombe, C. Ospelkaus, A.M. Meier, E. Knill, D. Leibfried, D.J. Wineland, Phys. Rev. A 84, 030303 (2011)

N. Timoney, I. Baumgart, M. Johanning, A.F. Varón, M.B. Plenio, A. Retzker, C. Wunderlich, Nature 476, 185 (2011)

N. Timoney, V. Elman, S. Glaser, C. Weiss, M. Johanning, W. Neuhauser, C. Wunderlich, Phys. Rev. A 77, 052334 (2008)

A. Khromova, C. Piltz, B. Scharfenberger, T.F. Gloger, M. Johanning, A.F. Varón, C. Wunderlich, arXiv:1112.5302v1 [quant-ph] (2011)

M. Johanning, A.F. Varón, C. Wunderlich, J. Phys. B 42, 154009 (2009)

J. Welzel, A. Bautista-Salvador, C. Abarbanel, V. Wineman-Fisher, C. Wunderlich, R. Folman, F. Schmidt-Kaler, arXiv:1102.3645v2 (2011)

D. Mc Hugh, J. Twamley, Phys. Rev. A 71, 012315 (2005)

H. Wunderlich, C. Wunderlich, K. Singer, F. Schmidt-Kaler, Phys. Rev. A 79, 052324 (2009)

C.A. Harper, Handbook of Thick Film Hybrid Microelectronics (McGraw-Hill Book, New York, 1974)

T.K. Gupta, Handbook of Thick- and Thin-Film Hybrid Microelectronics (Wiley, New York, 2005)

M. Merkel, K.-H. Thomas, Taschenbuch der Werkstoffe, 7th edn. (Carl Hanser, Munich, 2008)

C.D. Park, S.M. Chung, X.H. Liu, Y.L. Li, J. Vac. Sci. Technol. 26, 1166 (2008)

I. Weisgerber, Aufbau eines Magnetfeldsystems, eines Helixresonators und eines optischen Strahlenganges. Dipl., University of Hamburg, Hamburg (2003)

W.W. Macalpine, R.O. Schildknecht, Proc. IRE 47, 2099 (1959)

P. Vizmuller, R.F. Design Guide, Systems, Circuits, and Equations (Artech House, London, 1995)

A.I. Zverev, Handbook of Filter Synthesis (Wiley, New York, 1967)

Electric field generator, German Patent application de 10 2011 001 399.7, filed on march 18, 2011

C. Balzer, A. Braun, T. Hannemann, C. Paape, M. Ettler, W. Neuhauser, C. Wunderlich, Phys. Rev. A 73, 041407 (2006)

M. Johanning, A. Braun, D. Eiteneuer, C. Paape, C. Balzer, W. Neuhauser, C. Wunderlich, Appl. Phys. B 103, 327 (2011)

D. Kielpinski, M. Cetina, J.A. Cox, F.X. Kärtner, Opt. Lett. 31, 757 (2006)

C. Schneider, Entwicklung eines Objektivs hoher numerischer Apertur zum Nachweis der Resonanzfluoreszenz einzelner gespeicherter Ionen. M.Sc., University of Siegen, Siegen (2007)

D. Eiteneuer, Bau und Charakterisierung einer Ytterbium-Quelle für mikrostruktierte Ionenfallen. M.Sc., University of Siegen, Siegen (2009)

C. Wunderlich, G. Morigi, D. Reiß, Phys. Rev. A 72, 023421 (2005)

A. Albrecht, A. Retzker, C. Wunderlich, M.B. Plenio, New J. Phys. 13 (2011)

Acknowledgements

We gratefully acknowledge our electrical and mechanical work shops, and especially D. Gebauer who accomplished the thick-film printing for our chip carrier. We thank Andrés F. Varón for fruitful discussions. We acknowledge financial support by the European Union (STREP Microtrap and PICC), by the Deutsche Forschungsgemeinschaft and by secunet AG.

Author information

Authors and Affiliations

Corresponding author

Appendix A: Technical details

Appendix A: Technical details

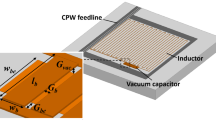

The microtrap chip carrier consists of a 15 mm thick block of alumina with outer dimensions of 65 mm×75 mm. It was milled by MicroCeram GmbH Meissen. The thick film printing of the block was carried out by the Hybrid Laboratory of the University of Siegen.

For the thick-film prints, isolating paste DuPont 5704, gold paste DuPont 5722L, and silver–palladium paste DuPont LF 121 were used. As the thickness of the alumina block is about 15 times higher than typical thick-film printed ceramics, the firing process had to be adjusted. Instead of a standard 50 K/min slope, a maximum velocity of 20 K/min was implemented. The maximum temperature of 850 °C was held for 20 min instead the typical 10 min. The whole cycle lasted 120 min. The typical height of printed thick film structures is 7–11 μm.

For the polishing procedure, polishing heads with a ring-shaped end face were built of aluminium to be able to just polish the ring shaped areas of isolation paste described above. The polishing heads were equipped with special cloth for the polishing pastes, Winter-Diamant polishing cloth D0,7–D0,25 of Saint Gobain Diamantwerkzeuge. The polishing heads were then mounted on a drilling machine, operating at 480 rounds per minute, and the isolation rings were polished for about 10 s with diamond-pastes Winter-Diaplast N D 0,7 with a particle size of 0.7 μm or N D 0,25 with a particle size of 0.25 μm with small force.

After this, the surface was checked under a light cut microscope. Typically, after two or three polishing cycles, the surface no longer showed the screen printing structure and was smoothly polished. On such a surface, the indium seals were always tight.

For the sealing, indium wire with a diameter of 0.5 mm and a pureness of 99.99 % was used. Before putting the indium wire onto the surfaces, a diminutive amount of vacuum grease Pfeiffer Vacuum BN845805-T was applied. After that, the indium was formed to a ring of a diameter according to the diameter of the isolating rings. The endings of the indium wire were crossed over each other, before putting the indium ring onto the surface.

The pastes used in thick-film technology are hardening slowly during storage and processing and the viscosity rises perceptibly. We believe this is the reason that in some of our prints, we found small leaks along a few radial wires when leak testing with helium, presumably caused by micro channels. As a precaution, we applied a narrow layer of leak sealing Torr Seal Vacuum Epoxy, Varian, along the edges of the isolating pastes to seal all potential channels and found that this procedure results in helium-tight interfaces reliably. We expect this sealing step to be unnecessary, when using fresh paste with low viscosity for thick-film printing.

Detailed design guidelines specific for the thick-film printing facilities at Siegen are available upon request from the authors.

Rights and permissions

About this article

Cite this article

Kaufmann, D., Collath, T., Baig, M.T. et al. Thick-film technology for ultra high vacuum interfaces of micro-structured traps. Appl. Phys. B 107, 935–943 (2012). https://doi.org/10.1007/s00340-012-4951-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-4951-7