Abstract

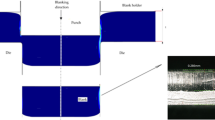

Sheet metal punching is an important industrial process for forming mechanical parts. Aimed at generating holes on thick sheets, punching process has been considered as a promising solution for the heavy industrial sector. The correct punching parameters choice has a direct influence on the hole quality. Since there exists rarely an analytical expression describing the relationships between these process parameters, the forming variable choice follows a series of costly try-and-error procedures on the workshop floor. The numerical simulation is a powerful tool that helps the forming engineers at the try-and-error procedures. This work shows the possibility of using FE-simulations to reduce the number of experiments that has to be conducted propitiating an increased understanding concerning some punching process parameters influence. The aim is the study of the clearance influence on the punched holes quality, 8 mm LNE38 sheet metal. Clearances of 0.2% up to 15% between the punch and die were analyzed. The influence of the punch–die clearance on the crack propagation was also analyzed, and the results were in agreement with the literature, i.e., good results for gaps within the traditional ideal range and occurrence of burr for clearance of 15%.

Similar content being viewed by others

References

Al-Momani E, Rawabdeh I (2008) An application of finite element method and design of experiments in the optimization of sheet metal blanking process. J Mech Indust Eng 2:53–63

Hatanaka N, Yamaguchi K, Takakura N (2003) Finite element simulations of the shearing mechanism in the blanking of sheet metal. J Mater Process Technol 139:64–70

Hatanaka N, Yamaguchi K, Takakura N, Iizuka T (2003) Simulation of sheared edge formation blanking of sheet metals. J Mater Process Technol 140:628–634

Li JH, Du H, Niu YS, Fu XL (2002) Research of the plastic status parameter and instantaneous clearance of a punching without burr. J Mater Process Technol 129:305–309

Söderberg M (2006) Finite element simulation of punching. Dissertation, Luleå, Sweden: Luleå University of Technology: ISSN 1402–1617

Husson C, Correia JPM, Daridon L, Ahzi S (2008) Finite elements simulations of thin copper sheets blanking: study of blanking parameters on sheared edge quality. J Mater Process Technol 199:74–83

Fang G, Zeng P, Lou L (2002) Finite element simulation of the effect of clearance on the forming quality in blanking process. J Mater Process Technol 122:249–254

Lin JC, Lin WS, Lee KS, Tong JL (2008) The optimal clearance design of micro-punching die. J Achievements Mat Manuf Eng 29:79–82

Mello LB, Marcondes PVP (2006) Punching and broaching combos—a new stamping tool. J Braz Soc Mech Sci Eng 28:94–98

Marcondes PVP, Eto AM, Beltrão PAC, Borges PC (2008) A smart stamping tool for punching and broaching combination. J Mater Process Technol 206:188–193

Ahzi S, Daridon L, Correia JPM, Husson C (2008) Finite elements simulations of thin copper sheets blanking: study of blanking parameters on sheared edge quality. J Mater Process Technol 199:74–83

Hilditch TB, Hodgson PD (2005) Development of the sheared edge in the trimming of steel and light metal sheet. J Mater Process Technol 169:192–198

Goijaerts AM, Govaert LE, Baaijens FPT (2001) Evaluation of ductile fracture models for different metals in blanking. J Mater Process Technol 110:312–323

Komori K (2001) Simulation of shearing by node separation method. Comput Struct 76:197–207

Wu Tsu-Te (2008) A proposed methodology for strain-based failure criteria. ASME Pressure Vessels and Piping Division Conference July 27–31, Chicago, Illinois

Hambli R (2002) Design of experiment based analysis for sheet metal blanking processes optimisation. Int J Manufact Technol 19:403–410

ABAQUS/CAE (2009) User's manual, version 6.9. ABAQUS Inc.

Marcondes PVP, Lajarin SF, Magalhães JFS (2007) Influence of the mesh format, refinement and way of application on sheet forming simulation. 19th International Congress of Mechanical Engineering-COBEM 2007, Brasília/DF/Bazil

Altan T (1998) Metal forming handbook, Schuler. Springer-Verlag Berlin Heidelberg, New York, pp 281–282

Klingenberg W, Singh UP (2006) Further observations and review of numerical simulations of sheet metal punching. Int Journal Adv Manufaturing Technology 30:638–644

Peng L, Liu F, Ni J, Lai X (2007) Size effects in thin sheet metal forming and its elastic–plastic constitutive model. Mater Des 28:1731–1736

Vaz MJ, Bressan JD (2002) A computational approach to blanking processes. J Mater Process Technol 126:206–212

Taupin E, Breitling J, Wu W-T, Altan T (1996) Material fracture and burr formation in blanking results of FEM simulations and comparison with experiments. J Mater Process Technol 59:68–78

Hambli R (2002) Prediction of burr height formation in blanking processes using neural network. Int J Mech Sci 44:2089–2102

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soares, J.A., Gipiela, M.L., Lajarin, S.F. et al. Study of the punch–die clearance influence on the sheared edge quality of thick sheets. Int J Adv Manuf Technol 65, 451–457 (2013). https://doi.org/10.1007/s00170-012-4184-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4184-2