Abstract

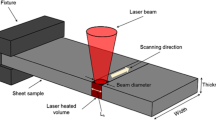

Recently, laser bending has received the attention for a wide variety of applications in industries due to its excellent bend quality with high productivity and flexibility. In this work, finite element simulations of bending of small sized sheets are carried out using ABAQUS package. The temperature and strain-rate dependent material properties of D36 shipbuilding steel sheet are considered. Simulation results throw light on the bending behavior of small sized sheet components.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Dixit, U. S., Joshi, S. N., & Kumar, V. H. (2013). Microbending with lasers. In V. K. Jain (Ed.), Micromanufacturing processes. Boca Raton: CRC Press.

Geiger, M., & Vollertsen, F. (1993). The mechanisms of laser forming. CIRP Annals Manufacturing Technology, 42, 301–304.

Hu, Z., Labudovic, M., Wang, H., & Kovacevic, R. (2001). Computer simulation and experimental investigation of sheet metal bending using laser beam scanning. International Journal of Machine Tools and Manufacture, 41, 589–607.

Ji, Z., & Wu, S. (1998). FEM simulation of the temperature field during the laser forming of sheet metal. Journal of Materials Processing Technology, 74, 89–95.

Labeas, G. N. (2008). Development of a local three-dimensional numerical simulation model for the laser forming process of aluminium components. Journal of Materials Processing Technology, 207, 248–257.

Li, W., & Yao, Y. L. (2001). Numerical and experimental investigation of convex laser forming process. Journal of Manufacturing Processes, 3, 73–81.

Liu, J., Sun, S., & Guan, Y. (2009). Numerical investigation on the laser bending of stainless steel foil with pre-stresses. Journal of Materials Processing Technology, 209, 1580–1587.

Merklei, M., Hennige, T., & Geiger, M. (2001). Laser forming of aluminum and aluminum alloys microstructural investigation. Journal of Materials Processing Technology, 115, 159–165.

Pretorius, T. (2009). Laser forming. In J. Dowden (Ed.), The theory of laser materials processing (Vol. 119, pp. 281–314). UK: Springer.

Shichun, W., & Jinsong, Z. (2001). An experimental study of laser bending for sheet metals. Journal of Materials Processing Technology, 110, 160–163.

Smith, T.M., Michaleris, P., Reutzel, E.W., & Hall, B. (2012). Finite element model of pulsed laser forming. In the 13th International Symposium on Laser Precision Microfabrication.

Thomson, G., & Pridham, M. (2001). Material property changes associated with laser forming of mild steel components. Journal of Materials Processing Technology, 118, 40–44.

Vásquez-Ojeda, C., & Ramos-Grez, J. (2009). Bending of stainless steel thin sheets by a raster scanned low power CO2 laser. Journal of Materials Processing Technology, 209, 2641–2647.

Walczyk, D. F., Vittal, S., & York, N. (2000). Bending of titanium sheet using laser forming. Journal of Manufacturing Processes, 2, 258–269.

Wang, X., Xu, W. X., Xu, W. J., Hu, Y. F., Liang, Y. D., & Wang, L. J. (2011). Simulation and prediction in laser bending of silicon sheet. Transactions of Nonferrous Metals Society of China, 21, s188–s193.

Zhanga, L., Reutzelb, E. W., & Michalerisc, P. (2004). Finite element modeling discretization requirements for the laser forming process. International Journal of Mechanical Sciences, 46, 623–637.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this chapter

Cite this chapter

Fetene, B.N., Dixit, U.S. (2015). Finite Element Simulations of Laser Bending of Small Sized Sheets. In: Joshi, S., Dixit, U. (eds) Lasers Based Manufacturing. Topics in Mining, Metallurgy and Materials Engineering. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2352-8_3

Download citation

DOI: https://doi.org/10.1007/978-81-322-2352-8_3

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2351-1

Online ISBN: 978-81-322-2352-8

eBook Packages: EngineeringEngineering (R0)