Abstract

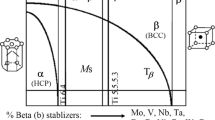

This chapter reviews the main difficulties impairing the machinability of titanium alloys. The overview of machinability of titanium alloys is presented with respect to the following performance criteria: cutting tool wear/tool life, cutting forces, chip formation, and surface integrity attributes, mainly surface roughness. Thereafter, the effects of various lubrication and cooling methods in machining titanium alloys is also discussed. Furthermore, a case study on the metallic particle emission when machining Ti-6A1-4V is also presented.

An erratum to this chapter is available at DOI 10.1007/978-3-662-43902-9_7

An erratum to this chapter can be found at http://dx.doi.org/10.1007/978-3-662-43902-9_7

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ezugwu E, Wang Z (1997) Titanium alloys and their machinability—a review. J Mater Process Technol 68:262–274. doi:10.1016/S0924-0136(96)00030-1

Khettabi R, Fatmi L, Masounave J, Songmene V (2013) On the micro and nanoparticle emission during machining of titanium and aluminum alloys. CIRP J Manuf Sci Technol 6:175–180. doi:10.1016/j.cirpj.2013.04.001

Ezugwu E, Bonney J, Yamane Y (2003) An overview of the machinability of aeroengine alloys. J Mater Process Technol 134:233–253. doi:10.1016/S0924-0136(02)01042-7

Hughes J, Sharman A, Ridgway K (2006) The effect of cutting tool material and edge geometry on tool life and workpiece surface integrity. Proc Inst Mech Eng Part B J Eng Manuf 220:93–107. doi:10.1243/095440506X78192

Sun J, Guo Y (2009) A comprehensive experimental study on surface integrity by end milling Ti–6Al-4V. J Mater Process Technol 209:4036–4042. doi:10.1016/j.jmatprotec.2008.09.022

Hong H, Riga AT, Gahoon JM, Scott CG (1993) Machinability of steels and titanium alloys under lubrication. J Wear, Part A 162–164:34–39. doi:10.1016/0043-1648(93)90481-Z

Ohkubo C, Watanabe I, Ford JP, Nakajima H, Hosoi T, Okabe T (2000) The machinability of cast titanium and Ti–6Al-4V. J Biomaterials 21:421–428. doi:10.1016/S0142-9612(99)00206-9

Watanabe I, Kiyosue S, Ohkubo C, Aoki T, Okabe T (2002) Machinability of cast commercial titanium alloys. J Biomed Mat Res 63:760–764. doi:10.1002/jbm.10413

Rahman M, Wong YS, Zareena AR (2003) Machinability of titanium alloys. JSME Int J Ser C 46:107–115. doi:10.1299/jsmec.46.107

Arrazola PJ, Garay A, Iriarte LM, Armendia M, Marya S, Le Maître F (2009) Machinability of titanium alloys (Ti6Al4V and Ti555.3). J Mater Process Technol 209:2223–2230. doi:10.1016/j.jmatprotec.2008.06.020

Kikuchi M (2009) The use of cutting temperature to evaluate the machinability of titanium alloys. Acta Biomater 5:770–775. doi:10.1016/j.actbio.2008.08.016

Rashid RR, Sun S, Wang G, Dargusch M (2011) Machinability of a near beta titanium alloy. Proc Inst Mech Eng Part B J Eng Manuf 225:2151–2162. doi:10.1177/2041297511406649

Dandekar CR, Shin YC, Barnes J (2010) Machinability improvement of titanium alloy (Ti–6Al-4V) via LAM and hybrid machining. Int J Mach Tools Manuf 50:174–182. doi:10.1016/j.ijmachtools.2009.10.013

Khanna N, Garay A, Iriarte LM, Soler D, Sangwan KS, Arrazola PJ (2012) Effect of heat treatment conditions on the machinability of Ti64 and Ti54M alloys. Procedia CIRP 1:477–482. doi:10.1016/j.procir.2012.04.085

Khanna N, Sangwan KS (2013) Comparative machinability study on Ti54M titanium alloy in different heat treatment conditions. Proc Inst Mech Eng Part B J Eng Manuf 227:96–101. doi:10.1177/0954405412466234

Yang JHN, Brandt M, Sun SJ (2009) Numerical and experimental investigation of the heat-affected zone in a laser-assisted machining of Ti-6Al-4V alloy process. Mater Sci Forum 618–619:143–146. doi:10.4028/www.scientific.net/MSF.618-619.143

Hong SY, Ding Y (2001) Cooling approaches and cutting temperatures in cryogenic machining of Ti-6Al-4V. Int J Mach Tools Manuf 41:1417–1437. doi:10.1016/S0890-6955(01)00026-8

Hong SY, Markus I, Jeong W (2001) New cooling approach and tool life improvement in cryogenic machining of titanium alloy Ti-6Al-4V. Int J MachTools Manuf 41:2245–2260. doi:10.1016/S0890-6955(01)00041-4

Palanisamy S, McDonald SD, Dargusch MS (2009) Effects of coolant pressure on chip formation while turning Ti6Al4V alloy. Int J Mach Tools Manuf 49:739–743. doi:10.1016/j.ijmachtools.2009.02.010

An QL, Fu YC, Xu JH (2011) Experimental study on turning of TC9 titanium alloy with cold water mist jet cooling. Int J Mach Tools Manuf 51:549–555. doi:10.1016/j.ijmachtools.2011.03.005

Balout B, Songmene V, Masounave J (2007) An experimental study of dust generation during dry drilling of pre-cooled and pre-heated workpiece materials. J Manuf Processes 9:23–34. doi:10.1016/S1526-6125(07)70105-6

Khanna N, Sangwan K (2010) Cutting Tool Performance in Machining of Ti555. 3, Timetal® 54M, Ti 6-2-4-6 and Ti 6-4 Alloys: A Review and Analysis. In: Proceedings of 2nd CIRP international conference on process machine interactions, June 10–11, 2010, Vancouver

Rahim EA, Sharif S (2006) Investigation on tool life and surface integrity when drilling Ti-6Al-4V and Ti-5Al-4V-Mo/Fe. JSME Int J Ser C 49:340–345. doi:10.1299/jsmec.49.340

Chen L, El-Wardany T, Harris W (2004) Modelling the effects of flank wear land and chip formation on residual stresses. CIRP J Manuf Sci Technol 53:95–98. doi:10.1016/S0007-8506(07)60653-2

Che-Haron C, Jawaid A (2005) The effect of machining on surface integrity of titanium alloy Ti–6 %Al–4 %V. J Mater Process Technol 166:188–192. doi:10.1016/j.jmatprotec.2004.08.012

Wang Z, Rahman M, Wong Y (2005) Tool wear characteristics of binderless CBN tools used in high-speed milling of titanium alloys. J Wear 258:752–758. doi:10.1016/j.wear.2004.09.066

Amin A, Ismail AF, Nor Khairusshima M (2007) Effectiveness of uncoated WC–Co and PCD inserts in end milling of titanium alloy—Ti–6Al-4V. J Mater Process Technol 192:147–158. doi:10.1016/j.jmatprotec.2007.04.095

Sun S, Brandt M, Dargusch M (2009) Characteristics of cutting forces and chip formation in machining of titanium alloys. Int J Mach Tools Manuf 49:561–568. doi:10.1016/j.ijmachtools.2009.02.008

Thomas M, Turner S, Jackson M (2010) Microstructural damage during high-speed milling of titanium alloys. Scr Mater 62:250–253. doi:10.1016/j.scriptamat.2009.11.009

Ginting A, Nouari M (2007) Optimal cutting conditions when dry end milling the aeroengine material Ti–6242S. J Mater Process Technol 184:319–324. doi:10.1016/j.jmatprotec.2006.10.051

Ginting A, Nouari M (2009) Surface integrity of dry machined titanium alloys. Int J Mach Tools Manuf 49:325–332. doi:10.1016/j.ijmachtools.2008.10.011

Che-Haron CH (2001) Tool life and surface integrity in turning titanium alloy. J Mater Process Technol 118:231–237. doi:10.1016/S0924-0136(01)00926-8

Sridhar B, Devananda G, Ramachandra K, Bhat R (2003) Effect of machining parameters and heat treatment on the residual stress distribution in titanium alloy IMI-834. J Mater Process Technol 139:628–634. doi:10.1016/S0924-0136(03)00612-5

Mantle A, Aspinwall D (1997) Surface integrity and fatigue life of turned gamma titanium aluminide. J Mater Process Technol 72:413–420. doi:10.1016/S0924-0136(97)00204-5

Mantle A, Aspinwall D (2001) Surface integrity of a high speed milled gamma titanium aluminide. J Mater Process Technol 118:143–150. doi:10.1016/S0924-0136(01)00914-1

Zoya Z, Krishnamurthy R (2000) The performance of CBN tools in the machining of titanium alloys. J Mater Process Technol 100:80–86. doi:10.1016/S0924-0136(99)00464-1

Kitagawa T, Kubo A, Maekawa K (1997) Temperature and wear of cutting tools in high-speed machining of Inconel 718 and Ti6Al 6V2Sn. J Wear 202:142–148. doi:10.1016/S0043-1648(96)07255-9

Nabhani F (2001) Machining of aerospace titanium alloys. Rob Comput Integr Manuf 17:99–106. doi:10.1016/S0736-5845(00)00042-9

Cui W, Jin Z, Guo A, Zhou L (2009) High temperature deformation behavior of α+β-type biomedical titanium alloy Ti–6Al–7Nb. Mater Sci Eng A 499:252–256. doi:10.1016/j.msea.2007.11.109

Karpat Y (2011) Temperature dependent flow softening of titanium alloy Ti6Al4V: an investigation using finite element simulation of machining. J Mater Process Technol 211:737–749. doi:10.1016/j.jmatprotec.2010.12.008

Sun S, Brandt M, Dargusch M (2010) The effect of a laser beam on chip formation during machining of Ti6Al4V alloy. Metall Mater Trans A 41:1573–1581. doi:10.1007/s11661-010-0187-5

Kahles J, Field M, Eylon D, Froes F (1985) Machining of titanium alloys. JOM 37:27–35

Honnorat Y (1996) Issues and breakthrough in the manufacture of turboengine titanium parts. Mater Sci Eng A 213:115–123. doi:10.1016/0921-5093(96)10229-X

Jawaid A, Sharif S, Koksal S (2000) Evaluation of wear mechanisms of coated carbide tools when face milling titanium alloy. J Mater Process Technol 99:266–274. doi:10.1016/S0924-0136(99)00438-0

Ghani JA, Che Haron CH, Hamdan SH, Md Said AY, Tomadi SH (2013) Failure mode analysis of carbide cutting tools used for machining titanium alloy. Ceram Int 39:4449–4456. doi:10.1016/j.ceramint.2012.11.038

Haron C, Ginting A, Arshad H (2007) Performance of alloyed uncoated and CVD-coated carbide tools in dry milling of titanium alloy Ti-6242S. J Mater Process Technol 185:77–82. doi:10.1016/j.jmatprotec.2006.03.135

Prengel H, Pfouts W, Santhanam A (1998) State of the art in hard coatings for carbide cutting tools. Surf Coat Technol 102:183–190. doi:10.1016/S0257-8972(96)03061-7

Ezugwu E, Da Silva RR, Bonney J, Machado A (2005) The effect of argon-enriched environment in high-speed machining of titanium alloy.Tribol Trans 48:l18–123. doi:10.1080/05698190590890290

M’saoubi R, Outeiro J, Changeux B, Lebrun J, Morao Dias A (1999) Residual stress analysis in orthogonal machining of standard and resulfurized AISI 316L steels. J Mater Process Technol 96:225–233. doi:10.1016/S0924-0136(99)00359-3

Liao Y, Shiue R (1996) Carbide tool wear mechanism in turning of Inconel 718 superalloy. J Wear 193:16–24. doi:10.1016/0043-1648(95)06644-6

Coromant S (1994) Modern metal cutting: a practical handbook: Sandvik Coromant, Sweden

Fujiwara J, Arimoto T, Tanaka K (2011) High speed milling of titanium alloy. Adv Mater Res 325:387–392. doi:10.4028/www.scientific.net/AMR.325.387

Zareena AR, Veldhuis SC (2012) Tool wear mechanisms and tool life enhancement in ultra-precision machining of titanium. J Mater Process Technol 212:560–570. doi:10.1016/j.jmatprotec.2011.10.014

Yang X, Richard Liu C (1999) Machining titanium and its alloys. J Mach Sci Tech 3:107–139. doi:10.1080/10940349908945686

Ezugwu E, Da Silva R, Bonney J, Machado A (2005) Evaluation of the performance of CBN tools when turning Ti–6Al-4V alloy with high pressure coolant supplies. Int J Mach Tools Manuf 45:1009–1014. doi:10.1016/j.ijmachtools.2004.11.027

Arunachalam R, Mannan M, Spowage A (2004) Residual stress and surface roughness when facing age hardened Inconel 718 with CBN and ceramic cutting tools. Int J Mach Tools Manuf 44:879–887. doi:10.1016/j.ijmachtools.2004.02.016

Arunachalam R, Mannan M, Spowage A (2004) Surface integrity when machining age hardened Inconel 718 with coated carbide cutting tools. Int J Mach Tools Manuf 44:1481–1491. doi:10.1016/j.ijmachtools.2004.05.005

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tools Manuf 51:250–280. doi:10.1016/j.ijmachtools.2010.11.003

Crawforth P, Wynne B, Turner S, Jackson M (2012) Subsurface deformation during precision turning of a near-alpha titanium alloy. Scr Mater 67:842–845. doi:10.1016/j.scriptamat.2012.08.001

Rotella G, Dillon OW, Umbrello D, Settineri L, Jawahir IS (2014) The effects of cooling conditions on surface integrity in machining of Ti6Al4V alloy. Int J Adv Manuf Technol 71:47–55. doi:10.1007/s00170-013-5477-9

El-Wardany T, Kishawy H, Elbestawi M (2000) Surface integrity of die material in high speed hard machining, Part 1: micrographical analysis. J Manuf Sci Eng 122:620–631. doi:10.1115/1.1286367

Dhar N, Kamruzzaman M, Ahmed M (2006) Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. J Mater Process Technol 172:299–304. doi:10.1016/j.jmatprotec.2005.09.022

Ramesh S, Karunamoorthy L, Palanikumar K (2008) Surface roughness analysis in machining of titanium alloy. J Mater Manuf Process 23:174–181. doi:10.1080/10426910701774700

Kumar Pandey A, Kumar Dubey A (2012) Simultaneous optimization of multiple quality characteristics in laser cutting of titanium alloy sheet. Opt Laser Technol 44:1858–1865. doi:10.1016/j.optlastec.2012.01.019

Vijay S, Krishnaraj V (2013) Machining Parameters Optimization in End Milling of Ti-6Al-4V. Proc Eng 64:1079–1088. doi:10.1016/j.proeng.2013.09.186

Ribeiro MV, Moreira MRV, Ferreira JR (2003) Optimization of titanium alloy (6Al–4V) machining. J Mater Process Technol 143–144:458–463. doi:10.16/S0924-0136(03)00457-6

Özel T, Zeren E (2007) Finite element modeling the influence of edge roundness on the stress and temperature fields induced by high-speed machining. Int J Adv Manuf Technol 35:255–267. doi:10.1007/s00170-006-0720-2

Venugopal KA, Paul S, Chattopadhyay AB (2007) Tool wear in cryogenic turning of Ti-6Al-4V alloy. J Cryo 47:12–18. doi:10.1016/j.cryogenics.2006.08.011

Calamaz M, Coupard D, Girot F (2008) A new material model for 2D numerical simulation of serrated chip formation when machining titanium alloy Ti–6Al-4V. J Mach Tools Manuf 48:275–288. doi:10.1016/j.ijmachtools.2007.10.014

Thepsonthi T, Özel T (2013) Experimental and finite element simulation based investigations on micro-milling Ti-6Al-4V titanium alloy: Effects of CBN coating on tool wear. J Mater Process Technol 213:532–542. doi:10.1016/j.cirp.2011.03.087

Ulutan D, Özel T (2012) Methodology to determine friction in orthogonal cutting with application to machining titanium and nickel based alloys. Proceedings of ASME 2012 international manufacturing science and engineering conference. Notre Dame, June 4–8, 2012. doi:10.1115/MSEC2012-7275

Axinte D, Dewes R (2002) Surface integrity of hot work tool steel after high speed milling-experimental data and empirical models. J Mater Process Technol 127:325–335. doi:10.1016/S0924-0136(02)00282-0

Ezugwu E (2005) Key improvements in the machining of difficult-to-cut aerospace superalloys. Int J Mach Tools Manuf 45:1353–1367. doi:10.1016/j.ijmachtools.2005.02.003

Wyen CF, Wegener K (2010) Influence of cutting edge radius on cutting forces in machining titanium. CIRP Ann Manuf Technol 59:93–96. doi:10.1016/j.cirp.2010.03.056

Ítalo Sette Antonialli A, Eduardo Diniz A, Pederiva R (2010) Vibration analysis of cutting force in titanium alloy milling. Int J Mach Tools Manuf 50:65–74. doi:10.1016/j.ijmachtools.2009.09.006

Germain G, Morel F, Lebrun JL, Morel A (2007) Machinability and surface integrity for a bearing steel and a titanium alloy in laser assisted machining. Lasers Eng

Sun S, Brandt M (2007) Laser-assisted machining of titanium alloys. Industrial lasers report, IRIS Swinburne University of Technology, Melbourne

Zitoune R, Krishnaraj V, Davim JP (2013) Laser assisted machining of titanium alloys. Mater Sci Forum 763:91–106. doi:10.4028/www.scientific.net/MSF.763.91

Wansheng Z, Zhenlong W, Shichun D, Guanxin C, Hongyu W (2002) Ultrasonic and electric discharge machining to deep and small hole on titanium alloy. J Mater Process Technol 120:101–106. doi:10.1016/S0924-0136(01)01149-9

Singh R, Khamba JS (2006) Ultrasonic machining of titanium and its alloys: a review. J Mater Process Technol 173:125–135. doi:10.1016/j.jmatprotec.2005.10.027

Singh R, Khamba JS (2007) Taguchi technique for modeling material removal rate in ultrasonic machining of titanium. Mater Sci Eng A 460:365–369. doi:10.1016/j.msea.2007.01.093

Singh R, Khamba JS (2007) Investigation for ultrasonic machining of titanium and its alloys. J Mater Process Technol 183:363–367. doi:10.1016/j.jmatprotec.2006.10.026

Hasçalık A, Çaydaş U (2007) Electrical discharge machining of titanium alloy (Ti–6Al-4V). Appl Surf Sci 253:9007–9016. doi:10.1016/j.apsusc.2007.05.031

Gente A, Hoffmeister HW, Evans C (2001) Chip formation in machining Ti6Al4V at extremely high cutting speeds. CIRP Ann Manuf Technol 50:49–52. doi:10.1016/S0007-8506(07)62068-X

Komanduri R, Hou ZB (2002) On thermoplastic shear instability in the machining of a titanium alloy (Ti-6Al-4V). Metall Mater Trans A 33:2995–3010. doi:10.1007/s11661-002-0284-1

Lee D (1985) The effect of cutting speed on chip formation under orthogonal machining. J Eng Ind 107:55–63. doi:10.1115/1.3185966

Bäker M, Rösler J, Siemers C (2002) Finite element simulation of segmented chip formation of Ti6Al4V. J Manuf Sci Eng 124:485–488. doi:10.1115/1.1459469

Hua J, Shivpuri R (2004) Prediction of chip morphology and segmentation during the machining of titanium alloys. J Mater Process Technol 150:124–133. doi:10.1016/j.jmatprotec.2004.01.028

Sheikh-Ahmad J, Quarless V, Bailey J (2004) On the role of microcracks on flow instability in low speed machining of CP titanium. J Mach Sci Tech 8:415–430. doi:10.1081/MST-200039867

Shivpuri R, Hua J, Mittal P, Srivastava A, Lahoti G (2002) Microstructure-mechanics interactions in modeling chip segmentation during titanium machining. CIRP Ann Manuf Technol 51:71–74. doi:10.1016/S0007-8506(07)61468-1

Calamaz M, Nouari M, Géhin D, Girot F (2006) Damage modes of straight tungsten carbide in dry machining of titanium alloy TA6V. J de Phy IV 134:1265–1271. doi:10.1051/jp4:2006134192

Bayoumi A, Xie J (1995) Some metallurgical aspects of chip formation in cutting Ti-6wt.% Al-4wt.% V alloy. Mater Sci Eng A 190:173–180. doi:10.1016/0921-5093(94)09595-N

Sorby K, Tonnessen K (2006) High-pressure cooling of face-grooving operations in Ti6Al4 V. Proc Inst Mech Eng Part B J Eng Manuf 220:1621–1627. doi:10.1243/09544054JEM474

Machado A, Wallbank J, Pashby I, Ezugwu E (1998) Tool performance and chip control when machining Ti6A14V and Inconel 901 using high pressure coolant supply. J Mach Sci Tech 2:1–12. doi:10.1080/10940349808945655

Vyas A, Shaw M (1999) Mechanics of saw-tooth chip formation in metal cutting. J Manuf Sci Eng 121:163–172. doi:10.1115/1.2831200

Obikawa T, Usui E (1996) Computational machining of titanium alloy—finite element modeling and a few results. J Manuf Sci Eng 118:208–215. doi:10.1115/1.2831013

Komanduri R, Von Turkovich B (1981) New observations on the mechanism of chip formation when machining titanium alloys. J Wear 69:179–188. doi:10.1016/0043-1648(81)90242-8

Barry J, Byrne G, Lennon D (2001) Observations on chip formation and acoustic emission in machining Ti–6Al-4V alloy. Int J Mach Tools Manuf 41:1055–1070. doi:10.1016/S0890-6955(00)00096-1

Ulutan D, Erdem Alaca B, Lazoglu I (2007) Analytical modelling of residual stresses in machining. J Mater Process Technol 183:77–87. doi:10.1016/j.jmatprotec.2006.09.032

Hua J, Umbrello D, Shivpuri R (2006) Investigation of cutting conditions and cutting edge preparations for enhanced compressive subsurface residual stress in the hard turning of bearing steel. J Mater Process Technol 171:180–187. doi:10.1016/j.jmatprotec.2005.06.087

Niknam SA, Songmene V (2014) Milling burr formation, modeling and control: a review. Proc Inst Mech Eng Part B J Eng. Manuf (In press)

Niknam SA, Kamguem R, Songmene V (2012) Analysys and optimization of exit burr size and surface roughness in milling using desireability function. Proceedings of ASME 2012 international mechanical engineering congress & Expo. Paper No. IMECE2012-86201. Houston, Nov 9–15, 2012. doi:10.1115/IMECE2012-86201

Niknam SA, Tiabi A, Kamguem R, Zaghbani I, Songmene V (2011) Milling burr size estimation using acoustic emission and cutting forces. Proc. of ASME Int Mech Eng Cong Expo. Paper No. IMECE2011-63824. Denver, Nov 11–17. doi:10.1115/IMECE2011-63824

Niknam SA, Songmene V (2012) Statistical investigation on burrs thickness during milling of 6061-T6 aluminium alloy. Proc of CIRP 1st Int Conf on Virtual Machining Process Technology, Montreal, 28 May–1 June 2012

Niknam SA, Songmene V (2014) Analytical modelling of slot milling exit burr siz. Int J Adv Manuf Tech (In press). doi: 10.1007/s00170-014-5758-y

Zedan Y, Niknam SA, Djebara A, Songmene V (2012) Burr size minimization when drilling 6061-T6 aluminum alloy. Proc of ASME 2012 Int Mech Eng Cong & Expo. Paper No. IMECE2012-86412. Houston, Nov 9–15, 2012. doi: 10.1115/IMECE2012-86412

Niknam SA (2013) Burrs understanding, modeling and optimization during slot milling of aluminium alloys. Ph.D. Thesis, École de Technologie Superieure, Universite du Quebec

Niknam SA, Songmene V (2013) Modeling of burr thickness in milling of ductile materials. Int J Adv Manuf Tech 66:2029–2039. doi:10.1007/s00170-012-4479-3

Niknam SA, Songmene V (2013) Factors governing burr formation during high-speed slot milling of wrought aluminium alloys. Proc Inst Mech Eng Part B J Eng Manuf 227:1165–1179. doi:10.1177/0954405413484725

Niknam SA, Songmene V (2013) Simultaneous optimization of burrs size and surface finish when milling 6061-T6 aluminium alloy. Int J Precis Eng Manuf 14:1311–1320. doi:10.1007/s12541-013-0178-8

Niknam SA, Songmene V (2013) Experimental investigation and modeling of milling burrs. Proc of ASME 2013 Int Manu Sci and Eng Conf, Madison, June 10–14, 2013. doi:10.1115/MSEC2013-1176

Niknam SA, Wygowski W, Balazinski M, Songmene V (2014) Milling burr formation and aavoidance. In: Davim JP (ed) Machinability of advanced materials, ISTE Wiley, London, pp 57–94. doi:10.1002/9781118576854.ch2

Tsann-Rong L (2000) Experimental study of burr formation and tool chipping in the face milling of stainless steel. J Mater Process Technol 108:12–20. doi:10.1016/S0924-0136(00)00573-2

Barth C, Dollmeier R, Warnecke G (2001) Burr formation in grinding of hardened steel with conventional and superabrasive wheels. Proc of North Am Manuf Res Conf 2001,Gainsville, 22–25 May 2001

Lin TR (2002) Optimisation technique for face milling stainless steel with multiple performance characteristics. Int J Adv Manuf Tech 19:330–335. doi:10.1007/s001700200021

Davim JP, Gaitonde V, Karnik SR (2007) Integrating Taguchi principle with genetic algorithm to minimize burr size in drilling of AISI 316L stainless steel using an artificial neural network model. Proc Inst Mech Eng Part B J Eng Manuf 221:1695–1704. doi:10.1243/09544054JEM863

Gaitonde VN, Karnik SR, Achyutha BT, Siddeswarappa B (2008) Taguchi optimization in drilling of AISI 316L stainless steel to minimize burr size using multi-performance objective based on membership function. J Mater Process 202:374–379. doi:10.1016/j.jmatprotec.2007.08.013

Kim J, Min S, Dornfeld DA (2001) Optimization and control of drilling burr formation of AISI 304L and AISI 4118 based on drilling burr control charts. Int J Adv Manuf Tech 41:923–936. doi:10.1243/09544054JEM863

Karnik S, Gaitonde V, Davim JP (2007) Integrating Taguchi principle with genetic algorithm to minimize burr size in drilling of AISI 316L stainless steel using an artificial neural network model. Proc Inst Mech Eng Part B J Eng 221:1695–1704. doi: 10.1243/09544054JEM863

Aurich JC, Dornfeld D, Arrazola PJ, Franke V, Leitz L, Min S (2009) Burrs-analysis, control and removal. CIRP Ann Manuf Technol 58:519–542. doi:10.1016/j.cirp.2009.09.004

Dornfeld DA, Kim JS, Dechow H, Hewson J, Chen LJ (1999) Drilling burr formation in titanium alloy, Ti-6AI-4V. CIRP Ann Manuf Technol 48:73–76. doi:10.1016/S0007-8506(07)63134-5

Schueler G, Engmann J, Marx T, Haberland R, Aurich J (2010) Burr formation and surface characteristics in micro-end milling of titanium alloys. Proceedings of the CIRP international conference on Burrs, April 2–3, 2009, University of Kaiserslautern, Germany. doi:10.1007/978-3-642-00568-8

Konig W (1978) Applied research on the machinability of titanium and its alloys. Proc AGARD Conf in Advanced Fabrication Processes, Florence

Sun J, Guo Y (2008) A new multi-view approach to characterize 3D chip morphology and properties in end milling titanium Ti–6Al-4V. Int J Mach Tools Manuf 48:1486–1494. doi:10.1016/j.ijmachtools.2008.04.002

Ibrahim G, Haron C, Ghani J (2009) The effect of dry machining on surface integrity of titanium ally Ti-6Al-4V. J Appl Sci 9:121–127

Puerta Velasquez JD (2007) Etude des copeaux et de l’intégrité de surface en usinage à grande vitesse de l’alliage de titane TA6V

Velásquez J, Tidu A, Bolle B, Chevrier P, Fundenberger JJ (2010) Sub-surface and surface analysis of high speed machined Ti–6Al-4V alloy. Mater Sci Eng A 527:2572–2578. doi:10.1016/j.msea.2009.12.01

Mhamdi M, Boujelbene M, Bayraktar E, Zghal A (2012) Surface integrity of titanium alloy Ti-6Al-4V in ball end milling. Phys Procedia 25:355–362. doi:10.1016/j.phpro.2012.03.096

Moussaoui K, Mousseigne M, Senatore J, Lagarrigue P, Caumel Y (2013) Influence of milling on surface integrity of Ti-6Al-4V. Adv Mat Res 698:127–136. doi:10.4028/www.scientific.net/AMR.698.127

Sadeghi M, Haddad M, Tawakoli T, Emami M (2009) Minimal quantity lubrication-MQL in grinding of Ti–6Al-4V titanium alloy. Int J Adv Manuf Tech 44:487–500. doi:10.1007/s00170-008-1857-y

Shokrani A, Dhokia V, Newman ST (2012) Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int J Mach Tools Manuf 57:83–101. doi:10.1016/j.ijmachtools.2012.02.002

Rahman M, Wang ZG, Wong YS (2006) A review on high-speed machining of titanium alloys. JSME JSME Int J Ser C 49:11–20

Nath KSG, Srivastava AK, Iverson J (2014) Study of droplet spray behavior of an atomization-based cutting fluid spray system for machining titanium alloys. J Manuf Sci. doi:10.1115/1.4025504

Hafenbraedl D, Malkin S (2001) Technology environmentaly correct for intern cylindrical grinding, Mach Metals Magaz 426:40–55

Su Y, He N, Li L, Li XL (2006) An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed end milling of Ti-6Al-4V. J Wear 261:760–766. doi:10.1016/j.wear.2006.01.013

Heisel U, Lutz D, Wassmer R, Walter U (1998) The minimum quantity lubricant technique and its application in the cutting process. Mach Metals Magaz 386:22–38

Hong SY, Zhao Z (1999) Thermal aspects, material considerations and cooling strategies in cryogenic machining. J Clean Products Process 1:107–116. doi:10.1007/s100980050016

O’sullivan D, Cotterell M (2001) Temperature measurement in single point turning. J Mater Process Technol 118:301–308. doi:10.1016/S0924-0136(01)00853-6

Niknam SA, Kouam J, Songmene V (2014) Experimental investigation on surface finish, burr formation and particles emission during slot milling of 6061-T6 aluminum alloy. Proceedings of ASME 2014 international mechanical engineering congress & Expo IMECE2014, Nov 14–20, 2014, Montreal

Dhar N, Islam M, Islam S, Mithu M (2006) The influence of minimum quantity of lubrication (MQL) on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel. J Mater Process Technol 171:93–99. doi:10.1016/j.jmatprotec.2005.06.047

Yue Y, Sun J, Gunter K, Michalek D, Sutherland J (2004) Character and behavior of mist generated by application of cutting fluid to a rotating cylindrical workpiece. Part 1: model development. J Manuf Sci Eng 126:417–425. doi:10.1115/1.1765150

Chen D, Sarumi M, Al-Hassani S (1998) Computational mean particle erosion model. J Wear 214:64–73. doi:10.1016/S0043-1648(97)00210-X

Chen Z, Stephenson DA, Wong K, Li W, Liang SY (2001) Cutting fluid aerosol generation due to spin-off in turning operation: analysis for environmentally conscious machining. J Manuf Sci Eng 123:506–512. doi:10.1115/1.1367268

Chen Z, Atmadi A, Stephenson DA, Liang SY, Patri KV (2000) Analysis of cutting fluid aerosol generation for environmentally responsible machining. CIRP Ann Manuf 49:53–56. doi:10.1016/S0007-8506(07)62894-7

Chen Z, Liang SY, Yamaguchi H (2002) Predictive modeling of cutting fluid aerosol generation in cylindrical grinding. Soc Manuf Eng (SME)196:1–8

Atmadi A, Stephenson A, Liang S (2001) Cutting fluid aerosol from splash in turning: analysis for environmentally conscious machining. Int J Adv Manuf Tech 17:238–243. doi:10.1007/s001700170175

Rossmoore H, Rossmoore L (1991) Effect of microbial growth products on biocide activity in metalworking fluids. Int J Biodeterior Biodegrad 27:145–156. doi:10.1016/0265-3036(91)90006-D

Sondossi M, Rossmoore H, Williams R (1989) Relative formaldehyde resistance among bacterial survivors of biocide-treated metalworking fluid. Int J Biodeterior Biodegrad 25:423–437. doi:10.1016/0265-3036(89)90068-7

Sutherland J, Kulur V, King N, Von Turkovich B (2000) An experimental investigation of air quality in wet and dry turning. CIRP Ann Manuf Technol 49:61–64. doi:10.1016/S0007-8506(07)62896-0

Zaghbani I, Songmene V, Khettabi R (2009) Fine and ultrafine particle characterization and modeling in high-speed milling of 6061-T6 aluminum alloy. J Mater Eng Perform 18:38–49. doi:10.1007/s11665-008-9265-x

Songmene V, Masounave J, Balout B (2008) Clean machining: experimental investigation on dust formation part II: influence of machining parameters and chip formation, part II. Int J Environ Conscious Des Manuf(ECDM) 14:17–33

Khettabi R, Songmene V, Masounave J (2007) Effect of tool lead angle and chip formation mode on dust emission in dry cutting. J Mater Process Technol 194:100–109. doi:10.1016/j.jmatprotec.2007.04.005

Khettabi R, Songmene V, Masounave J (2010) Effects of speeds, materials, and tool rake angles on metallic particle emission during orthogonal cutting. J Mater Eng Perform 19:767–775. doi:10.1007/s11665-009-9551-2

Khettabi R, Songmene V, Zaghbani I, Masounave J (2010) Modeling of particle emission during dry orthogonal cutting. J Mater Eng Perform 1919:776–789. doi:10.1007/s11665-009-9538-z

Khettabi R, Songmene V, Masounave J, Zaghbani I (2008) Understanding the formation of nano and micro particles during metal cutting. Int J Syst Signal control Eng appl 1:203–210

Khettabi R, Songmene V (2009) Particle emission during orthogonal and oblique cutting. Int J Adv Mach and Form Oper 1:1–9

Ezugwu EO (2005) Key improvements in the machining of difficult-to-cut aerospace superalloys. Int J Mach Tools Manuf 45:1353–1367. doi:10.1016/j.ijmachtools.2005.02.003

Khettabi R, Fatmi L, Masounave J, Songmene V (2013) On the micro and nanoparticle emission during machining of titanium and aluminum alloys, CIRP. J Manufact Sci Technol 6:175–180. http://dx.doi.org/10.1016/j.cirpj.2013.04.001

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Niknam, S.A., Khettabi, R., Songmene, V. (2014). Machinability and Machining of Titanium Alloys: A Review. In: Davim, J. (eds) Machining of Titanium Alloys. Materials Forming, Machining and Tribology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-43902-9_1

Download citation

DOI: https://doi.org/10.1007/978-3-662-43902-9_1

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-43901-2

Online ISBN: 978-3-662-43902-9

eBook Packages: EngineeringEngineering (R0)