Abstract

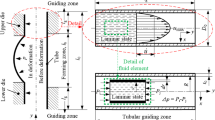

The expansion of tubes by direct application of gas detonation waves or electromagnetic forming (EMF) is an alternative forming method for hollow section workpieces. In particular, the process can be used for typical hydro-formed parts, car body or exhaust elements in the automotive industry, for example. The introduced processes belong to the category of high speed forming methods and provide typical advantages, such as higher achievable strains, compared to quasistatic methods using high water pressure. Another advantage of these processes is the avoidance of high contact forces by employing an “inertia-locked tool” system due to the extremely short process time. To develop a controllable process it is essential to gain a good knowledge of the interactions in the system. This can be achieved by using simulations in combination with experimental investigations; their results are the topic of this paper. Also included are special investigations of the material behavior at high strain rates.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Lesemann, M., Sahr, C., Hart, S., Taylor, R.: SuperLIGHT-CAR – the Multi-Material Car Body. In: Proceedings of the 7th LS-DYNA Anwenderforum, Bamberg (2008)

Kleiner, M., Geiger, M., Klaus, A.: Manufacturing of Lightweight Components by Metal Forming. In: Annals of the CIRP Manufacturing Technology, 53rd General Assembly of CIRP, vol. 52(2), pp. 521–542 (2003)

Psyk, V., Risch, D., Kinsey, B.L., Tekkaya, A.E., Kleiner, M.: Electromagnetic forming – A review. J. Mater. Process. Tech (2011), doi: 10.1016/j.jmatproctec.2010.12.012

Beerwald, C.: Grundlagen der Prozessauslegung und –gestaltung bei der elektromagnetischen Umformung. Dr. Ing. Dissertation, TU Dortmund (2005)

Kaden, H.: Wirbelströme und Schirmung in der Nachrichtentechnik. Springer, Berlin (1959)

Weber, M., Hermes, M., Brosius, A., Beerwald, C., Gersthteyn, G., Olivier, H., Kleiner, M., Bach, F.-W.: Process Investigation of Tube Expansion by Gas Detonation. In: Proceedings of the International Conference on High Speed Forming (ICHSF) 2006, pp. 161–174 (2006) ISBN 3-00-018432-5

Esser, B.: Die Zustandsgrößen im Stoßwellenkanal als Ergebnisse eines exakten Riemannlösers. Dissertation, RWTH Aachen (1991)

Bathe, K.J.: Finite Elemente Methoden, 2nd edn. Springer, Berlin (2002)

Psyk, V., Beerwald, C., Homberg, W., Kleiner, M.: Extension of Forming Limits by Using a Process Combination of Electromagnetic Forming and Hydroforming. In: Proceedings of the 8th International Conference on Technology of Plasticity, ICTP (2005) ISBN 88-87331-74-X

Psyk, V.: Prozesskette Krümmen – Elektromagnetisch Komprimieren – Innenhochdruckumformen für Rohre und profilförmige Bauteile. Dr. Ing. Dissertation, TU Dortmund (2010) ISBN 978-3-8322-9026-9

Gottstein, G., Shvindlerman, L.S.: Grain boundary migration in metals: thermodynamics, kinetics, applications, vol. 385. CRC Press, Boca Raton (1999)

Johnston, W.G., Gilman, J.J.: Dislocation Velocities, Dislocation Densities and Plastic Flow in Lithium Fluoride Crystals. Journal of Applied Physics 30(2), 129 (1959)

Gottstein, G.: Physik. Grundlagen der Materialkunde. Springer, Berlin (2001)

Roos, A.: Fast-moving dislocations in high strain rate deformation. Groningen University Press (1999)

Alshitz, V.I., Indenbom, V.L.: Dynamic dragging of dislocations. Soviet Physics Uspekhi 18(1) (1975)

Mattissen, D.: Insitu Untersuchung des Einflusses der Tripelpunkte auf die Korngrenzenbewegung in Aluminium, Dissertation, RWTH Aachen (2004)

Czubayko, M.: Korngrenzenbewegung in Aluminium und Zink, Dissertation, RWTH Aachen (1998)

Vovk, V.T.: Gasexplosion als Werkzeug in der Fertigungstechnik. Habilitation, Magdeburg, Univ. (1999)

Psyk, V., Gershteyn, G., Demir, O.K., Brosius, A., Tekkaya, A.E., Schaper, M., Bach, F.-W.: Process Analysis and Physical Simulation of Electromagnetic Joining of Thin-Walled Parts. In: Proceedings of the International Conference on High Speed Forming, pp. 181–190 (2008) ISBN: 3-9809535-3-X

Kreimeyer, M., Wagner, F., Zerner, I., Sepold, G.: Laser beam joining of aluminium with titanium with the use of an adapted working head. In: DVS-Berichte, vol. 212, pp. 317–321. DVS-Verlag, Düsseldorf (2001)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Bach, F.W., Kleiner, M., Tekkaya, A.E. (2013). Investigation of the Complex Interactions during Impulse Forming of Tubular Parts. In: Denkena, B., Hollmann, F. (eds) Process Machine Interactions. Lecture Notes in Production Engineering. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-32448-2_23

Download citation

DOI: https://doi.org/10.1007/978-3-642-32448-2_23

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-32447-5

Online ISBN: 978-3-642-32448-2

eBook Packages: EngineeringEngineering (R0)