Abstract

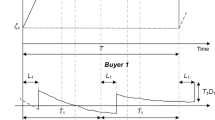

This paper presents the mathematical derivation of a new generation of the most largely used periodic review policy in supply chain: the coordinated (S, R) replenishment rule. We first derive the classical order-up-to model and then we modify it to generate the coordinated decision policy equations. We run a numerical simulation on a serial supply chain model to show differences in the two policies. We conclude on the managerial implications related to coordinated replenishment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

McKinsey & Co.: Evaluating the impact of alternative store formats. Supermarket Industry Convention, Food Marketing Institute, Chicago (1992)

Cachon, G., Fisher, M.: Campbell Soup’s continuous replenishment program: Evaluation and enhanced inventory decision rules. Productions and Operations Management 6, 266–276 (1997)

Disney, S.M., Towill, D.R.: The effect of vendor managed inventory (VMI) dynamics on the Bullwhip Effect in supply chains. International Journal of Production Economics 85, 199–215 (2003)

Andraski, J.C.: Foundations for a successful continuous replenishment programme. International Journal of Logistics Management 5, 1–8 (1994)

VICS Merchandising Issue Committee, CPFR Committee: Collaborative Planning, Forecasting, and Replenishment Guidelines.Voluntary Interindustry Commerce Standards Associations, Lawrenceville (1998)

Holmström, J., Främling, K., Kaipia, R., Saranen, J.: Collaborative planning forecasting and replenishment: new solutions needed for mass collaboration. Supply Chain Management: An International Journal 7, 136–145 (2002)

Lee, H.L., Padmanabhan, V., Whang, S.: Information distortion in a supply chain: the bullwhip effect. Management Science 43, 546–558 (1997)

Cannella, S., Ciancimino, E.: On the Bullwhip Avoidance Phase: Supply Chain Collaboration and Order Smoothing. International Journal of Production Research (2009)

Cachon, G., Fisher, M.: Supply chain inventory management and the value of shared information. Management Science 46, 1032–1048 (2000)

Disney, S.M., Towill, D.R.: A discrete transfer function model to determine the dynamic stability of a vendor managed inventory supply chain. International Journal of Production Research 40, 179–204 (2002)

Chatfield, D.C., Kim, J.G., Harrison, T.P., Hayya, J.C.: The bullwhip effect - Impact of stochastic lead time, information quality, and information sharing: A simulation study. Production and Operations Management 13, 340–353 (2004)

Shang, J.S., Li, S., Tadikamalla, P.: Operational design of a supply chain system using the Taguchi method, response surface methodology, simulation, and optimization. International Journal of Production Research 42, 3823–3849 (2004)

Kelepouris, T., Miliotis, P., Pramatari, K.: The impact of replenishment parameters and information sharing on the Bullwhip effect: a computational study. Computers and Operations Research 35, 3657–3670 (2008)

Holweg, M., Disney, S.M., Holmström, J., Småros, J.: Supply chain collaboration: making sense of the strategy continuum. European Management Journal 23, 170–181 (2005)

Disney, S.M.: The Dynamics of Material Flows in Supply Chains, http://ssrn.com/abstract=1013326

Wang, Y.C.: Evaluating flexibility on order quantity and delivery lead time for a supply chain system. International Journal of Systems Science 39, 1193–1202 (2008)

Boute, R.N., Disney, S.M., Lambrecht, M.R., Van Houdt, B.: Designing replenishment rules in a two-echelon supply chain with a flexible or an inflexible capacity strategy. International Journal of Production Economics 119, 187–198 (2009)

Kulp, S.C., Ofek, E., Whitaker, J.: Supply-Chain Coordination: How Companies Leverage Information Flows to Generate Value. In: Harrison, T.P., Lee, H.L., Neale, J. (eds.) The practice of supply chain management. Where theory and practice converge, pp. 91–107. Springer, New York (2004)

Hax, A.C., Candea, D.: Production and Inventory Management. Prentice-Hall, Englewood Cliffs (1984)

Disney, S.M., Lambrecht, M.R.: On Replenishment Rules, Forecasting, and the Bullwhip Effect in Supply Chains. Foundations and Trends in Technology, Information and Operations Management 2, 1–80 (2008)

Boute, R.N., Disney, S.M., Lambrecht, M.R., Van Houdt, B.: A win-win solution for the bullwhip problem. Production Planning and Control 19, 702–711 (2008)

Simon, H.A.: On the application of servomechanism theory to the study of production control. Econometrica 20, 247–268 (1952)

Holt, C.C., Modigliani, F., Muth, J.F., Simon, H.A.: Planning Production, Inventories and Work Force. Prentice-Hall, Englewood Cliffs (1960)

Forrester, J.: Industrial Dynamics. MIT Press, Cambridge (1961)

Clark, A.J., Scarf, H.: Optimal Policies for a Multi-Echelon Inventory Problem. Management Science 6, 475–490 (1960)

Whang, S.: Coordination in operations: a taxonomy. Journal of Operations Management 12, 413–422 (1995)

Dong, L., Lee, H.L.: Optimal policies and approximations for a serial multiechelon inventory system with time-correlated demand. Operations Research 51, 969–980 (2003)

Swaminathan, J.M., Tayur, S.R.: Models for supply chains in e-Business. Management Science 49, 1387–1406 (2003)

DeCroix, G.A.: Optimal policy for a multiechelon inventory system with remanufacturing. Operations Research 54, 532–543 (2006)

Chen, F., Drezner, Z., Ryan, J.K., Simchi-Levi, D.: Quantifying the bullwhip effect in a simple Supply Chain: the impact of forecasting, lead-times and information. Management Science 46, 436–443 (2000)

Sterman, J.D.: Modelling managerial behaviour: misperceptions of feedback in a dynamic decision-making experiment. Management Science 35, 321–339 (1989)

Wikner, J., Towill, D.R., Naim, M.M.: Smoothing supply chain dynamics. International Journal of Production Economics 22, 231–248 (1991)

Van Ackere, A., Larsen, E.R., Morecroft, J.D.W.: Systems thinking and business process redesign: An application to the beer game. European Management Journal 11, 412–423 (1993)

John, S., Naim, M.M., Towill, D.R.: Dynamic analysis of a WIP compensated decision support system. International Journal of Management Systems Design 1, 283–297 (1994)

Crespo Márquez, A., Bianchi, C., Gupta, J.N.D.: Operational and financial effectiveness of e-collaboration tools in supply chain integration. European Journal of Operational Research 159, 348–363 (2004)

Machuca, J.A.D., Del Pozo Barajas, R.: A computerized network version of the Beer Game via the Internet. System Dynamics Review 13, 323–340 (1997)

Jakšič, M., Rusjan, B.: The effect of replenishment policies on the bullwhip effect: a transfer function approach. European Journal of Operational Research 184, 946–961 (2008)

Wright, D., Yuan, X.: Mitigating the bullwhip effect by ordering policies and forecasting methods. International Journal of Production Economics 113, 587–597 (2008)

Dejonckheere, J., Disney, S.M., Lambrecht, M.R., Towill, D.R.: The impact of information enrichment on the bullwhip effect in Supply Chains: A control engineering perspective. European Journal of Operational Research 153, 727–750 (2004)

Dejonckheere, J., Disney, S.M., Lambrecht, M.R., Towill, D.R.: Measuring and avoiding the bullwhip effect: A control theoretic approach. European Journal of Operational Research 147, 567–590 (2003)

Kim, J.G., Chatfield, D., Harrison, T.P., Hayya, J.C.: Quantifying the bullwhip effect in a supply chain with stochastic lead time. European Journal of Operational Research 173, 617–636 (2006)

Agrawal, S., Sengupta, R.N., Shanker, K.: Impact of information sharing and lead time on bullwhip effect and on-hand inventory. European Journal of Operational Research 192, 576–593 (2009)

Ciancimino, E., Cannella, S., Canca Ortiz, J.D., Framiñán, J.M.: Supply chain multi-level analysis: two bullwhip dampening approaches [Análisis multinivel de cadenas de suministros: Dos técnicas de resolución del efecto bullwhip]. Revista de Métodos Cuantitativos para la Economía y la Empresa 8, 7–28 (2009)

Hosoda, T., Naim, M.M., Disney, S.M., Potter, A.: Is there a benefit to sharing market sales information? Linking theory and practice. Computers and Industrial Engineering 54, 315–326 (2008)

Mason, R., Lalwani, C., Boughton, R.: Combining vertical and horizontal collaboration for transport optimization. Supply Chain Management 12, 187–199 (2007)

Cannella, S., Ciancimino, E., Márquez, A.C.: Capacity constrained supply chains: A simulation study. International Journal of Simulation and Process Modelling 4, 139–147 (2008)

Ciancimino, E., Cannella, S.: Modelling the bullwhip effect dampening practices in a limited capacity production network. LNBIP, vol. 20, pp. 475–486. Springer, Heidelberg (2009)

Gaalman, G., Disney, S.M.: A new inventory policy for a two echelon supply chain. In: Euroma conference, Göteborg (2009)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2010 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Cannella, S., Ciancimino, E. (2010). Up-to-Date Supply Chain Management: The Coordinated (S, R) Order-Up-to. In: Dangelmaier, W., Blecken, A., Delius, R., Klöpfer, S. (eds) Advanced Manufacturing and Sustainable Logistics. IHNS 2010. Lecture Notes in Business Information Processing, vol 46. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-12494-5_16

Download citation

DOI: https://doi.org/10.1007/978-3-642-12494-5_16

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-12461-7

Online ISBN: 978-3-642-12494-5

eBook Packages: Computer ScienceComputer Science (R0)