Abstract

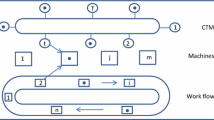

This paper discusses design of flexible manufacturing systems (FMSs) in one or multiple rows. Evolutionary computation, particularly genetic algorithms (GAs) proved to be successful in search of optimal solution for this type of problems. The model of solution, the most suitable way of coding the solutions into the organisms and the selected evolutionary and genetic operators are presented. In this connection, the most favourable number of rows and the sequence of devices in the individual row are established by means of genetic algorithms (GAs). In the end the test results of the application made and the analysis are discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Balic, J.: Flexible manufacturing systems, DAAAM International, Vienna (2001)

Hamiani, A., Popescu, G.: A knowledge-based expert system for site layout, Computing in Civil Engineering: Microcomputers to Supercomputers, pp. 248–256. ASCE, New York (1988)

Kusiak, A.: Intelligent Manufacturing Systems. Prentice-Hall, New Jersey (1990)

Tompkins, J.A., White, J.A., Bozer, Y.A., Frazelle, E.H., Tanchoco, J.M., Trevino, J.: Facilities Planning. John Wiley & Sons, New York (1996)

Chiang, W.C., Kouvelis, P.: Improved Tabu search heuristics for heuristics for solving facility layout problems. International Journal of Production Research 34(9), 2565–2585 (1996)

Heragu, S., Kusiak, A.: Machine layout problem in flexible manufacturing systems. Operations Research 36, 258–268 (1988)

Li, H., Love, E.D.: Genetic search for solving construction site-level unequal-area facility layout problems. Automation in Construction 9, 217–226 (2000)

Tsourveloudis, N., Ioannidis, S., Valavanis, K.: Fuzzy surplus based distributed control of manufacturing system. Advances in Production Engineering & Management 1(1), 5–12 (2006)

Curkovic, P., Jerebic, B.: Honey-bees optimization algorithm applied to path planning problem. International journal of simulation modelling 6(3), 154–164 (2007)

Viraj, T., Ajai, J.: Assessing the effectiveness of flexible process plans for loading and part type selection in FMS. Advances in Production Engineering & Management 3(1), 27–44 (2008)

Heng, L., Love, E.D.: Genetic search for solving construction site-level unequal-area facility layout problems. Automation in Construction 9, 217–226 (2000)

Gen, M., Cheng, R.: Genetic Algorithms And Engineering Design. J. Wiley & Sons, New York (1997)

Goldberg, D.E., Lingle, R.: Alleles, loci and the traveling salesman problem. In: Proc. 1st Conference on Genetic Algorithms, pp. 154–159 (1985)

Tavakkoli-Moghaddain, R., Shayan, E.: Facilities layout design by genetic algorithms. Computers industrial Engineering 35(3-4), 527–530 (1998)

Osman, H.M., Georgy, M.E., Ibrahim, M.E.: A hybrid CAD-based construction site layout planning system using genetic algorithms. Automation in construction 12, 749–764 (2003)

Author information

Authors and Affiliations

Editor information

Rights and permissions

Copyright information

© 2008 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Ficko, M., Balic, J. (2008). Design of Row-Based Flexible Manufacturing System with Evolutionary Computation. In: Lovrek, I., Howlett, R.J., Jain, L.C. (eds) Knowledge-Based Intelligent Information and Engineering Systems. KES 2008. Lecture Notes in Computer Science(), vol 5178. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-85565-1_1

Download citation

DOI: https://doi.org/10.1007/978-3-540-85565-1_1

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-540-85564-4

Online ISBN: 978-3-540-85565-1

eBook Packages: Computer ScienceComputer Science (R0)