Abstract

This paper focusses on modelling expert knowledge resources for preventive maintenance. Expert knowledge resources are defined as those employees engaged in a company’s external maintenance who are important in the realisation of maintenance activities in the supported industries as well as those employees whose work is focussed on the application of knowledge. The aim of this work is to elaborate methods for acquiring and formalising this expert knowledge, in order to improve the manner of giving instructions via manuals, currently in use in maintenance areas. The approach presented in the form an IT tool, dedicated to the automotive industry, is implemented.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

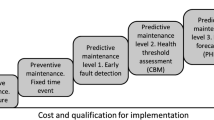

Ahmad, R., Kamaruddin, S.: An overview of time-based and condition-based maintenance in industrial application. Comput. Ind. Eng. 63, 135–149 (2012)

Bevilacqua, M., Braglia, M.: The analytic hierarchy process applied to maintenance strategy selection. Reliab. Eng. Syst. Saf. 70, 71–83 (2000)

Bocewicz, G., Muszyński, W., Banaszak, Z.: Models of multimodal networks and transport processes. Bull. Pol. Acad. Sci. Tech. Sci. 63(3), 635–650 (2015)

Bouzidi-Hassini, S., Tayeb, F.B., Marmier, F., Rabahi, M.: Considering human resource constraints for real joint production and maintenance schedules. Comput. Ind. Eng. 90, 197–211 (2015)

Dudek, A., Patalas-Maliszewska, J.: A model of a tacit knowledge transformation for the service department in a manufacturing company: a case study. Found. Manag. 8(1), 176–177 (2016)

Fan, H.: Business Strategic Management: Knowledge Capital and Integration of Core Competence. Shanghai Foreign Language Education Press, Shanghai (2004)

Google Cloud Platform. https://cloud.google.com/video-intelligence/

Johnsen, T., Howard, M., Miemczyk, J.: UK defence change and the impact on supply relationships. Supply Chain Manag. Int. J. 14(4), 270–279 (2009)

Lemke, J.: Analyzing Verbal Data: Principles, Methods, and Problems. Springer International Handbooks of Education, vol. 24, pp. 1471–1484 (2012)

Masood, T., Royand, R., Harrison, A., Xu, Y., Gregson, S., Reeve, C.: Integrating through-life engineering service knowledge with product design and manufacture. Int. J. Comput. Integrated Manuf. 28(1), 59–74 (2015)

Murthy, D.N.P., Rausand, M., Østerås, T.: Product Reliability Specification and Performance. Springer, London (2008)

Nielsen, P., Michna, Z., Do, N.A.D., Sørensen, B.B.: Lead times and order sizes-A not so simple relationship. Adv. Intell. Syst. Comput. 429, 65–75 (2016)

Öhmana, M., Finneb, M., Holmströma, J.: Measuring service outcomes for adaptive preventive maintenance. Int. J. Prod. Econ. 170(B), 457–467 (2015)

Patalas-Maliszewska, J., Krebs, I: Decision model for the use of the application for knowledge transfer support in manufacturing enterprises. In: Abramowicz, W. (ed.) Business Information Systems Workshops 2015, LNBIP. Springer International Publishing, Heidelberg (2015)

Wang, S., Liu, M.: Multi-objective optimization of parallel machine scheduling integrated with multi-resources preventive maintenance planning. J. Manufacturing Syst. 37, 182–192 (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Patalas-Maliszewska, J., Kłos, S. (2019). Modelling of Knowledge Resources for Preventive Maintenance. In: Rodríguez, S., et al. Distributed Computing and Artificial Intelligence, Special Sessions, 15th International Conference. DCAI 2018. Advances in Intelligent Systems and Computing, vol 801. Springer, Cham. https://doi.org/10.1007/978-3-319-99608-0_6

Download citation

DOI: https://doi.org/10.1007/978-3-319-99608-0_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-99607-3

Online ISBN: 978-3-319-99608-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)