Abstract

Most studies on multi-use concepts of aquaculture and wind farms explored cultivation feasibility of extractive species, such as seaweed or bivalves. However, recent studies also included the cultivation of crustaceans or fish culture in the vicinity of wind turbines. Consequently, new approaches combine fed and extractive species in integrated multi-trophic aquaculture (IMTA) concepts for offshore multi-use to reduce nutrient output and the overall environmental impact of aquaculture operations. In this chapter the findings of a series of mussel and oyster cultivation experiments over several seasons are presented, which were conducted at different offshore test sites in the German Bight. Sites were selected within future offshore wind farm areas for an explicit multi-use perspective. Results have demonstrated successful growth and fitness parameters of these candidates and therefore definitely proved the suitability of these bivalve extractive species for open ocean aquaculture. Another approach for multi-use in offshore wind farms is its use as marine protected area or even for reinforcement or restoration of endangered species, which need the absence of any fisheries activity for recovery. Current projects are testing this perspective for the native European oyster Ostrea edulis and the European lobster Homarus gammarus. From the technological point of view there are many options on how to connect aquaculture devices, such as longline and ring structures as well as different cage types, to the foundations as well as to install it in the centre of the free area between wind turbines. Next to the system design also experiments on drag forces originating from the aquaculture structure on the foundation and vice versa were investigated. Complementary to the biological, environmental end technical aspects, a number of studies were specifically targeted to address and include stakeholders, their attitudes, their interests and concerns over time. By this approach, the inclusion of stakeholders into the research process from its very beginning until today, co-production of knowledge could be fostered. Next to joint identification of the major impediments and concerns of offshore aquaculture under multi-use conditions, new issues and research questions were identified. Primary focus on the economic potential of aquaculture in offshore wind farms was shown for consumption mussels. The production of mussels using longline technology is sufficiently profitable even under the assumption of substantial cost increases. This is especially true, if existing capacities could be used. Last but not least, the EEZ is a special area—it is not a state territory even if a coastal state has its sovereign rights and jurisdiction. It is an area where three legal systems come together: international law, law of the European Union and national law. There are no mariculture projects in the German EEZ and no approval procedure has been completed so far. Some sites are not suitable for mariculture, especially because of nature conservation and shipping.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The development of “offshore aquaculture” or “open ocean aquaculture” has often been described as the new challenging frontier of the “Blue Revolution”, which puts current aquaculture efforts on the same level as the advances made in agriculture during the so-called “Green Revolution” in the onset of the 1950s (Krause et al. 2015). The motivation to foster this type of marine development roots against the backdrop of the rising concerns that the over-exploitation and economic inefficiencies in the capture-fisheries sector are leading to widespread severe decline of global food security. However, to date, the search for resilient solutions in the aquaculture sector to meet production, income, community development and food supply and security needs remains critical.

In contrast to nearshore aquaculture development, offshore aquaculture faces several additional challenges, one of which is that in Germany it is located in the EEZ, the Exclusive Economic Zone. The latter is defined by United Nations Convention on the Law of the Sea (UNCLOS) as a 200 nautical mile zone off the coast of a State, over which it has special rights regarding the exploration and utilization of marine resources. Thus, the EEZ is a special area—it is not a state territory even if a coastal state has there somewhat sovereign rights and jurisdiction, which refers to the coastal state’s rights below the surface of the sea. As a case in point, in Germany, the EEZ is an area where three legal systems come together: international law, law of the European Union and national German law.

Indeed, the ocean space of the EEZ has been regulated or allocated in a number of different ways, but most importantly, this has been done predominantly within individual economic sectors. Obvious examples of ‘‘sectoral zoning’’ include waterways for shipping, disposal areas, military security zones, concession zones for mineral extraction, aquaculture sites, and most recently marine protected areas. Although the context and outcomes are different because of the dynamic and three-dimensional nature of marine environments, the land use planning concepts and techniques can be translated to the marine environment, thus leading to a contemporary rise in the development of Marine Spatial Planning (MSP) efforts. At present, there are few frameworks that facilitate integrated strategic and comprehensive planning in relation to all activities taking place in marine areas. This current stage of development of spatial planning of marine waters can be viewed somewhat in parallel to the past land use planning efforts. The latter arose in response to specific social and economic problems and later environmental problems that were triggered by the industrial revolution at the end of the 19th century.

Next to the problematic nature of marine spatial planning, the offshore realm is a place far off the coast, which bears challenges to the technological development of aquaculture systems that are able to withstand the harsh offshore conditions, vis á vis supporting feasible operation and maintenance demands. Candidate species must be tolerable to these exposed conditions whilst holding sufficient economic potential. Last, but not least, stakeholders and their interests, concerns, rights and duties must be taken into consideration.

In the following we illustrate these different aspects and challenges of offshore aquaculture in multi-use settings employing Germany’s North Sea EEZ region as a case study. We draw here on research and experience from various research efforts in this areas since early 2000 until today (see Buck et al. 2008a). Figure 11.1 shows a summary of the projects conducted in the German Bight all led by the Alfred Wegener Institute Helmholtz Centre for Polar and Marine Research (AWI), which were related to the four main topics: (A) biology, (B) technology, (C) social science as well as (D) economics.

Offshore aquaculture multi-use projects conducted in the German Bight under the guidance or participation of AWI from early 2000 ongoing. Next to the chronological order, all projects are configured in a scientific coherence manner. The project “TROPOS” is marked in a dotted line as it focused only partly on the German Bight. Additionally, there is a separate chapter in this book where this project is described in more detail. Project No. 11 “AquaInno” has only slight overlaps with multi-use aspects and therefore is not mentioned in detail. Project No. 12 “EuroTour” deals with site-selection and health status of offshore environments along the European Atlantic Coast. Project No. 16 focuses on restoration for nature conservation purposes. The Project No. 17 “MUSES” just started after submission of this book. Modified and updated after Buck et al. 2008a

All projects are displayed in a chronological order by taking the scientific coherence into account. Project No. 1, the feasibility study, gave the basis for the following projects and the entire suite of aquaculture-wind farm multi-use research. The Coastal Futures Project (No. 4) acted as key node project, in which the other projects either have contributed to or have been stimulated by its transdisciplinary approach. Due to their problem-focused approaches and early and continuous integration of multiple stakeholder groups, these projects initiated and accompanied several activities and outcomes outside academia. For instance, it called for wind farm planners attention to offshore aquaculture, included authorities and fishermen into the planning process for site-selection-criteria of appropriate aquaculture sites as well as stimulated the involvement of offshore engineers and wind farm operators into the technical part of an offshore aquaculture enterprise. Furthermore, it introduced fishermen to the co-management idea and appraised the potential economics of mussel cultivation, supplied authorities with maps and tools to limit regional stakeholder conflicts, and established an inshore reference station to support the data assessed offshore. All research undertakings over the entire period were conducted as follow-up projects resulting from addressing the issues of social acceptance, the demand for practical technical solutions and to fill some of the knowledge gaps in biology, social science and other related topics.

In the following sub-chapters, the central findings of these projects are discussed in more detail and the development of this contextual knowledge generation over time is synthesized. This will be done by starting with the potential species and their respective biological characteristics, which determine their feasibility for offshore aquaculture in the first place. In the successive sub-chapters, the prospective technologies to harness their potential as aquaculture products are discussed, as well as their likely economic potential for this contextual setting in the German Bight. The chapter closes with an overview over the existing stakeholder characteristics and their respective attitudes, perceptions and concerns and the respective regulatory framework.

2 The Beginning

The feasibility study (Project No. 1) (Buck 2000, 2001, 2002) aimed to ascertain the economic feasibility of an offshore marine aquaculture structure for breeding of marine organisms in the North Sea, predominantly in combination with an offshore wind farm. In the year 2000 several thousand wind-generators were planned for installation in the North Sea before the end of the decade. However, at that time, after completion of this feasibility study, no offshore wind farm was in use or in preparation. The major goal of this combination was to use environmentally-friendly wind-driven power generation, or so-called renewable energy production, with the environmental enhancement that aquaculture offers as a very important opportunity. This feasibility study concentrated on Open Ocean Aquaculture (OOA) and its multi-use potential with offshore wind farms.

Most countries with access to the sea are engaged in aquaculture. Only rare cases, for example in developing nations, fundamentals of e.g. technical knowledge, resisting equipment and system design are lacking to successfully research and implement aquaculture. Although Germany has the above-mentioned factors in relative abundance, it can be counted with the few developing nations that have not adopted any form of aquaculture. The reasons for this stagnation are mainly as follows: Conflicts exist between interested parties on coastal land management issues. Such parties include commercial and pleasure boat traffic, gravel mining, marine and local fishing coops, and protected areas, such as national parks. Problems with regulation and assignment of areas in the North Sea and its near-shore waters arose due to these conflicts. In addition, complex local hydrodynamic conditions such as large wave heights and strong water currents have hindered the aquaculture development in Germany.

“Offshore, Open Ocean, Far Out”—currently unknown or seldom used terms among the German public, have become since the mid-1990s common “catch-phrases” in Asia and the USA. In an effort to cover the immense demand for seafood products, new regions beneath the coastal waters were sought. However, at that time only a few world-wide Open Ocean Aquaculture businesses are in operation and are still a new method of aquaculture internationally. Main research efforts in an international perspective were placed in the provision of sturdy offshore technology, which resist the extreme environmental conditions and warrants safe utilisation of the installation. However, so far, little operational implementation of the results of extensive research has been undertaken.

Several types of cultivation in combination with the foundations of offshore wind turbines were suggested: (1) Predominately longline constructions for the cultivation of seaweed and mussels, by which submersible ropes provide the habitat on which the candidates can settle (Fig. 11.2a). (2) Other techniques, such as ring and cage constructions (Fig. 11.2b, c), which can be placed on the water surface and under water, as well as the construction SOSSEC (Submersible Offshore Shellfish and Seaweed Cage) (Fig. 11.2d) can be operated, too.

a–d First drawings to show the multi-use concept combining aquaculture with wind farms. a Top a birds-eye view of longline constructions. Special pylon anchorages ensure access and maintenance of the wind energy plants by ship; down Side view of a submerged mussel and seaweed longline culture. The wind energy plant pylon is used as the anchorage for one end of the longline. The line can reach a length of 100–300 m. Longer lines may be mounted to the next pylon; b Top A bird’s-eye view of a ring construction. The combined rings are fixed around the pylon as well as a pylon with a single offshore ring construction using two anchorages; down Side view of a pylon with offshore ring construction used for cultivation of algae and mussels. An anchor stone is placed at the outermost point of the ring construction; c Side view of a pylon combined with an ‘on bottom’ cage for oyster culture and oyster trays fixed to a longline as well as a rotating oyster cage (drum); d SOSSEC design (Submersible Offshore Shellfish and Seaweed Cage), which is during culture in a submerged mode and can be lifted to the surface for harvest. Modified after Buck (2000, 2001); Images AWI/Prof. Dr. Bela H. Buck

The advantage of submersible culture constructions is the avoidance of the impact of harsh weather conditions and strong wave mechanics. Thus, a combination of these techniques with the main pillar of the wind turbine installation dispenses the need for a sophisticated mooring of the aquaculture system, which would impact strongly on the benthic ecosystem. Due to the solid construction of the wind turbine, such systems would be very safe.

The feasibility study suggested a variety of candidates, which can be cultivated under such hydrodynamic and environmental conditions within the North Sea, and hold large potentials on the German market. Additionally, the study pointed to the technical challenges and the importance of the socio-economic drivers. All users have to be addressed at the beginning of a new project in order to find an overarching consensus of all parties thereto.

As predominately, already existing data sets were used in the feasibility study of offshore aquaculture potentials within the areas of wind farms in the German North Sea, this study was theoretical in nature. In order to determine the feasibility of aquaculture within the German North Sea, further experiments on a practical basis were conducted and led to the project development displayed in Fig. 11.1.

At the time when the study was published, we expected that the further development and modification of aquaculture systems would be directly dependent on the development of wind farms. Therefore, it was necessary that the development of future wind turbine techniques as well as aquaculture systems should not move ahead separately.

In summary, there was an ample need for practical research pertaining aquaculture development in the North Sea to overcome the current lack of knowledge in Germany in this sector.

3 Potential Species for Offshore Aquaculture

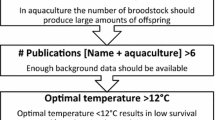

Suitable species for offshore aquaculture production in the German North Sea were identified during several scientific research projects. The selection was (1) based on literature research, (2) expert knowledge on candidate biology, (3) former projects as well as (4) confirmed by current practical research results. Accordingly, 21 aquaculture candidates of different trophic levels (extractive and fed species: seaweed, molluscs, crustacean and fish) are recommended for offshore cultivation in the German Bight (North Sea). In the following we present a collection of species tested starting with extractive species, followed by crustaceans and fish.

3.1 Seaweed Species

Seaweed aquaculture research in offshore sites focusses mainly on growth performance and culturing techniques. Various systems were installed in harsh offshore conditions, both at the wind farm foundation and at its vicinity (see subchapter on techniques and system design below), respectively. Following biological and ecological requirements, but also a regulatory and economic framework, five species of macroalgae were identified as potentially successful candidates for offshore cultivation in the German North Sea: Oarweed (Laminaria digitata), Sugar kelp (Saccharina latissima), Cuvie (Laminaria hyperborea), Dulse (Palmaria palmata), and Sea beech (Delesseria sanguinea).

3.1.1 Candidate: Laminarian Species

The genus Laminaria is one of the most important macroalgal genera in temperate coastal ecosystems, especially in the northern hemisphere. This is amongst other things reflected by its high species numbers, its considerable overall biomass, its dominance, and its economic significance (Bartsch et al. 2008). The utilisation of algal products plays an essential role in many fields of modern everyday life. Laminariales offer a variety of goods used in human and animal consumption, in industrial products or for bioremediation (Bartsch et al. 2008).

In the German North Sea, vital abundance of L. hyperborea, L. digitata and S. latissima is reduced to the rocky shore of the Island of Helgoland as the remaining coastline is characterized by soft-bottom substrate, not suitable for the fixation of Laminaria rhizoid holdfasts. For aquaculture production, Laminaria plants are “seeded” on ropes, which are subsequently fixed to various suspended or floating culture devices. Detaching L. digitata and S. latissima blade portions from the meristem induces them to become sporogenous far ahead of their natural reproductive season, making mature sporophytes available all year round (Buchholz and Lüning 1999; Lüning et al. 2000; Pang and Lüning 2004) (Fig. 11.3a–e).

a Rope with young Saccharina latissima 6 weeks after seeding; b Laminarian plants after 10 weeks cultivation in land based facilities; c Seeding rope used for offshore cultivation arranged in a “curtain”-mode before seeding; d Large S. latissima harvested from an offshore site after 5 months cultivation ready for the drying procedure; e Tank for seeding procedure and day-length adaptation. Photos a and d AWI/Dr. Cornelia Buchholz; b–c and e AWI/Prof. Dr. Bela H. Buck

In general, Laminaria in the German North Sea show a period of rapid growth from January to June and one of slow growth from July to September (Kain 1979). Helgolandic S. latissima and L. hyperborea predominantly grow in winter and early spring similarly as in Norway (Bartsch et al. 2008). While growth of L. hyperborea totally stops in July, growth of S. latissima decreases substantially but does not cease. In contrast, the growth period of L. digitata from Helgoland extends from spring to summer and in September, it exhibits a growth rate of still 50% of the optimum (Lüning 1979). The seasonal variations in abiotic conditions affect growth performance, particularly in algae from high latitudes with a more pronounced seasonality of temperature, irradiance and photoperiod (Bartsch et al. 2008).

Exploring the feasibility of offshore kelp cultures, potential forces experienced by the attached algae were studied extensively. Sporophytes were seeded on ropes, which were designed for the use in offshore environments (Fig. 11.3a, c). Land-based cultivation took place in tank devices, where the day length could be adapted according to the development of sorus (Fig. 11.3b, e). When Laminarian thalli reached market size (1.5–2.0 m in length) plants were harvested and transferred to the lab to test its dry weight ratio (Fig. 11.3d).

The degree of exposure influenced morphology and shape of the algae and their resistance to environmental forcing considerably. Laminaria originating from sheltered conditions had wider blades with thick and undulate margins, while offshore sporophytes grown at exposed sites were thin and streamlined (Bartsch et al. 2008; Buck and Buchholz 2005). S. latissima sporophytes pre-cultivated onshore but transferred to the sea at very early stages developed a streamlined blade and resisted current velocities up to 2.5 m s−1. If grown singly in currents of >1 mm s−1, S. latissima can withstand the high energy environment experienced in offshore cultivation (Buck and Buchholz 2005). These experiments on Laminaria species show that adapted to strong currents as young individuals, they will grow well and produce large amounts of biomass at exposed sites of the German Bight (Buck and Buchholz 2005; Fig. 11.4a, b).

a Saccharina latissima originating from a sheltered site with a wider blade and ruffled margins and b cultivated S. latissima from the offshore site with a streamlined shape (modified after Buck and Buchholz 2005). Photos AWI/Prof. Dr. Bela H. Buck

When combining Laminaria aquaculture with offshore wind farms, the foundations would provide a stable fixing structure for the seaweed cultivation systems (e.g. Buck 2002; Krause et al. 2003; Buck et al. 2004). These ideas led to several multi-use projects in the German Bight, such as No. 1–4, 9, 13, 15 (see Fig. 11.1) (Buck 2002; Michler-Cieluch et al. 2009a, b, Buck and Buchholz 2004a, 2005; Buck et al. 2012), where for the first time Laminaria species were tested in an IMTA approach with partners from the offshore wind industry.

Mass culture of Laminaria sp. and Saccharina latissima under the high energy offshore environment in the North Sea requires a rigid cultivation system for withstanding rough conditions, which can be handled while retaining the macroalgae. Buck and Buchholz (2004a) tested various carrier constructions and different mooring systems and their results led to a new patented ring carrier for macroalgae offshore cultivation (see subchapter on techniques and system design below) (Figs. 11.32 and 11.33).

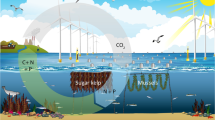

For IMTA approaches in the German Bight, the three native Laminaria species are ideal extractive candidates: Laminaria cultivation brings clear advantages for the environment. Apart from their CO2-consumption, kelps are also able to absorb large amounts of nitrogen and phosphate, thus helping to abate coastal eutrophication (McHugh 2003; Lüning and Pang 2003; Fei 2004) (see Chapter Offshore Aquaculture with Extractive Species: Seaweed and Bivalves). This feature of Laminaria and other seaweeds qualifies them for use in sustainable maricultures. Modern integrated aquaculture systems have been developed and are constantly improved. The combination of seaweed culture with land-based fish culture or open marine cage culture has found great acceptance (Subandar et al. 1993; Petrell and Alie 1996; Ahn et al. 1998; Troell et al. 1999; Chopin et al. 2001; Neori et al. 2004). Macroalgae, including Laminaria, may act as biofilters for finfish aquaculture at offshore sites in the German Bight, removing dissolved excretions and surplus nutrients and providing extra oxygen and biomass.

3.1.2 Candidate: Palmaria palmata

Dulse is an edible intertidal or shallow subtidal red alga (Rhodophyta) of the Atlantic and North Pacific and its culture methods are well known (Browne 2001; Le Gall et al. 2004; Pang and Lüning 2004, 2006) (Fig. 11.5a).

a–c Dulse (Palmaria palmata) grown in a land-based IMTA-system in co-culture with turbot for nutrient budget calculation for the multi-use of offshore wind farms. a Palmaria palmata (Photo AWI/Sina Löschke); b Palmaria palmata from IMTA tank culture (Photo AWI/Dr. Britta Grote); c IMTA tank system for cultivation of Palmaria palmata in project No. 15 “Offshore Site Selection”. The red macroalgae were grown in tumble culture (Photo AWI/Dr. Britta Grote)

P. palmata has been proven to be a good candidate for integrated multi-trophic aquaculture (IMTA) in the projects SEAPURA (Lüning 2001) and “Offshore Site Selection” (Project No. 15; Matos et al. 2006; Grote 2016; Grote and Buck 2017) and is thought to be a suitable species for cultivation in multi-use approaches in offshore wind farms (Grote and Buck 2017) (Fig. 11.5b, c). The red alga can reach specific growth rates (SGR) between 1.1% d−1 at 14 °C, 13–14 h daylight and varying radiation in co-culture with halibut (Corey et al. 2014) and 6.18% d−1 at 14 °C, 16 h daylight and constant radiation in co-culture with turbot (Grote and Buck 2017). Latter results are similar to the maximum SGR of P. palmata reaching 7% d−1 at 6–14 °C and 16 h daylight with nutrients added (Morgan and Simpson 1981). In an IMTA-system with turbot, the excess N of 1 kg fish supported the growth of more than 6.5 kg of dulse, which removed a maximum of 0.76 mg N mg DW−1 d−1 at 14 °C (Grote and Buck 2017). Conservative estimates of yields of P. palmata at about 300 t year−1 are expected to remove up to 30% of N excreted by 500 tonnes of salmon within two years (Sanderson et al. 2012).

Since P. palmata is one of the few seaweed in Europe used for food, its chemical composition has been investigated (Morgan et al. 1980a). In recent years, interest in health foods, food supplements, new protein sources and novel bioactive compounds led to further research of the chemicals found in seaweeds (Løvstad-Holdt and Kraan 2011; Indergaard and Minsass 1991). The red alga has also a relatively high protein content, which can be increased by IMTA cultivation, as the ammonium leads to increased N storage in the algal tissue (Grote 2016).

P. palmata requires a site with high water current for nutrient and CO2 exchange across the surface of the fronds as well as for prevention of fouling (Werner and Dring 2011), thus making it a good candidate for offshore cultivation. Currents with flow rates of minimum 5–10 cm s−1 are needed for Palmaria cultivation. However, the exposure of the site to wave action should be moderate (Werner and Dring 2011). Therefore, for offshore cultivation of dulse wave exposure and current velocities need to be considered to reach optimal growth conditions and to reduce loss of biomass.

Another limiting factor for growth of P. palmata in the wind farms of the German Bight is the relatively high water temperatures in summer. Grote and Buck (2017) found reduced SGRs of 2.2% d−1 at 16.5 °C. Minimum winter temperatures are not considered to be damaging unless there is the unlikely threat of ice-formation which could cause abrasion of the cultures. Growth of P. palmata is optimal at temperatures between 6° and 12 °C, but the red alga will grow well to temperatures up to 15 °C (Morgan et al. 1980b; Morgan and Simpson 1981) or 17 °C (Grote and Buck 2017), with these differences probably resulting from different temperature ranges for different populations.

The size at which P. palmata should be harvested is a frond length of 30–40 cm (Werner and Dring 2011). It is crucial to monitor the algae during spring and especially during the summer months to ensure that the dulse is harvested before the fronds are overgrown by fouling organisms (Werner and Dring 2011). This is very important when P. palmata is grown for human consumption, which requires high quality harvests. As growth is expected to be reduced during the summer months due to higher temperatures in the German Bight, the optimal time for harvest would be in June (Grote and Buck 2017). As the growth of P. palmata was enhanced in the vicinity of fish farms at sea (Sanderson et al. 2012) and as it is an robust alga thought to withstand strong forces, P. palmata is thought to be an ideal extractive candidate for offshore IMTA (Grote and Buck 2017). However, the potential forces experienced by the attached algae offshore need to be studied in more detail.

3.1.3 Candidate: Delesseria sanguinea

Sea beech is an European endemic, sublittoral red alga with a distribution range from northern Spain and Portugal to northern Norway and Iceland (Lüning 1990). It is thought to be a candidate for offshore aquaculture systems due to its biological tolerance to environmental conditions (Lüning 1990); however, biological studies on multi-use and offshore aquaculture success of this species are still missing. The reproductive season of D. sanguinea lasts from October to February/April at Helgoland (Molenaar and Breeman 1997) and the red alga can tolerate temperatures between 13 and 23 °C, but temperatures for optimal growth lie between 10 and 15 °C (Lüning 1990). D. sanguinea is used in the cosmetics industry for its anticoagulant properties and vitamin K content; the active principle being termed delesserine (Guiry and Blunden 1991).

3.2 Bivalve Species

Following mainly biological and technical requirements, but also a regulatory and economic framework, three filter-feeding bivalves were identified as potentially successful candidates for offshore cultivation in the German Bight: Mytilus edulis, Crassostrea gigas and Ostrea edulis (Buck et al. 2006a).

M. edulis and O. edulis are native species while C. gigas was introduced to German waters in the 1960s due to aquaculture activities in the Netherlands (Diederich et al. 2004; Smaal et al. 2009). By now C. gigas is distributed all over the German North Sea coastline and is commercially cultured since the 1980s. All three species are classified as extractive species in aquaculture and are therefore ideal candidates for offshore cultivation with IMTA concepts. They reduce nutrient emissions of higher trophic species by filter-feeding and require low maintenance as they do not require additionally feed (Pogoda et al. 2011).

During several studies, these candidates have been cultivated at various offshore sites and approved their suitability for offshore aquaculture operations in the future. Results of these studies clearly elucidated that all three bivalve species grow successfully under exposed conditions in offshore environments (e.g. Buck 2007; Brenner et al. 2012; Pogoda et al. 2011, 2013). As the “multi-use” of offshore wind farms for aquaculture installations will facilitate the further expansion of environmentally friendly and sustainable aquaculture, most test sites of the described cultivation experiments were conducted in North Sea areas of two offshore wind farms (OWF): “Butendiek” (in operation since 2015) and “Nordergründe”Footnote 1 (currently under construction in late 2016, Fig. 11.6).

3.2.1 Candidate: Mytilus edulis

Biological conditions: Blue mussels cultivated in offshore areas of the German North Sea, for the most part, show high growth rates compared to those grown in nearshore sites (e.g. Buck 2004, 2007). This is due to the fact that water quality (e.g. less urban sewage) and oxygen concentrations are more suitable and the infestation of parasites is low or non-existent (Buck et al. 2005; Pogoda 2012). However, in areas under estuarine influence and/or exposure to fluvial transport point to a comparable probability for high contamination loads similar to nearshore areas, thus potentially reducing fitness (Brenner et al. 2012). In Project No. 2 “Open Ocean Aquaculture” mooring devices were deployed to test the feasibility of mussel and seaweed aquaculture at offshore sites within areas of planned wind farms (Fig. 11.7a). Larval abundance of mussels tended to decrease with increasing distance from shore (Walter et al. 2002; Buck 2017). However, several offshore sites were identified, where larval concentration was sufficient enough to facilitate adequate natural seeding (Buck 2007) (Fig. 11.7b). Alternatively, limited spat availability may be viewed as an advantage when moving offshore. The benefit for a low settlement can lead to a one-step cultivation technique (no thinning procedure) if collecting and grow-out sites are within the same region in the vicinity of offshore structures. The lower settlement success on one hand results in a limited commercial potential, but on the other hand eases handling and maintenance (Fig. 11.7c). During Project No. 3 “Roter Sand”Footnote 2 different types of submerged longline systems were developed and tested: a conventional polypropylene longline as well as a steel hawser longline, both with different versions of buoyancy modes. Spat collectors and grow-out ropes were suspended perpendicular from the horizontal longline for several months. These multi-use experiments have shown a massive settlement at offshore cultivation lines, making thinning essential (Buck 2007) (Fig. 11.8).

a Shows the map indicating the stations where offshore test installations were moored; b displays the concentration of mussel larvae in the water column at the respective site and c represents the number of mussels settling on ropes (Buck 2017)

Map of the southern German Bight. The enlarged upper Inset illustrates the test area No. I, Nordergründe, and the test area No. II at the offshore lighthouse Roter Sand. The wind turbines indicate the planned offshore wind farm “Energiekontor” (modified after Buck 2007)

Resistance of mussels to severe conditions: The resistance of mussels to strong currents as well as high waves and swell depends on the degree and duration of these forces (Project No. 5 “MytiFit” and Project No. 10 “River Jade”). Information on hydrodynamic conditions is important due to the fact that e.g. mussels and oysters do adapt to harsh conditions but do not automatically grow fast. Even when flow rates are increasing and consequently deliver more food, which stimulates mussels and oysters to feed intensively, at a certain current velocity threshold growth is reduced due to a pressure differential between inhalant and exhalent siphons (Wildish and Kristmanson 1984, 1985; Rosenberg and Loo 1983). Further, exposure to high waves/swell also reduces production rates due to the loss of mussels through detachment (Scarratt 1993). Even if mussels cultivated in high energy environments are able to adapt to the permanent physical stress by increasing the strength and number of byssal-thread attachments, system design adapted from sheltered environments, such as collector devices, have to be modified to prevent detachment (Brenner and Buck 2010).

To follow the idea of multi-use of sites and support the co-existence of mussel cultivation off the coast in severe conditions where wind farms occur the attachment and detachment of mussels and their byssus threats from their holding devices were tested (Figs. 11.9a–c, 11.10 and 11.11a–m). Collector types for larval settlement attraction, good foothold and interweaving abilities, or collectors combining these properties should be developed and applied depending on the use for seed mussel collection or grow-out as well as for a one-step or a two-step (including thinning) cultivation method. Due to the harsh conditions in the open ocean collector surfaces should be precisely tailored to avoid loss of mussels. It may happen that not only one collector type for all purposes is the solution. Changing collector surfaces according to the prevailing conditions (current velocity, waves, size of the mussel, etc.) may be most beneficial.

a–c Investigation of the forces needed to detach mussels/byssus threads from substrates. a Dislodgement device with a force gauge; b sample and clamp to pick up a single mussel from a mussel conglomerate; c visible are various byssus threats when lifting up the clamp (modified after Brenner and Buck 2010)

Collector types used for the detachment test. ASW Artificial Seaweed Collector (Size [S]: 10 mm; Material [M]: nylon rope as back bone with 10 cm long PP-leaves attached at both sites; Origin [O]: Japan); LOC Looped Christmas Tree (M Extruded polypropylene with a straight trim, strands of lead in the centre help sinking; O New Zealand); LEC Leaded Christmas Tree (M Extruded polypropylene with a looped trim, strands of lead in the centre help sinking; O New Zealand); GAR Galician Rope (M Rough surfaced nylon-PE ropes with strands; O Spain); SSC Self-Sinking Collector (M Polyester net formed as a tube, small stones help sinking; O Norway); LAD Ladder Collector (S 16 mm; M Parallel running PP-ropes connected every 35 cm by a plastic bar; O Norway); AQU Aquamats® (M Strands of PP-fleece material with ballast sleeve; O USA); NFL Naue® Fleece (M PP-fleece, cost-saving alternative to AQU; O Germany); COC Coconut Rope (S 24 mm; M rope of coconut fibres; O India); REF Reference Collector (M Bushy tufts of a unravelled 10 mm PP-rope; O Germany) (modified after Brenner and Buck 2010)

a–m EM-photos (100-fold magnification) of mussel byssus threats/plaques attached to substrates. a Byssus plaque attached to a mussel shell. White arrows demonstrate the outstretched size of the plaque. b Byssus plaques on an ASW collector; c attached post-larvae on LEC collector and on d LAD collector; e byssus plaques on LEC collector; f attached post-larvae on COC collector; g byssus plaques and h attached post-larvae on NFL collector; i byssus plaques and k attached post-larvae on an SSC collector; m byssus plaques on an GAR collector (modified after Brenner and Buck 2010)

Use of fouling organisms originating from foundations: In Project No. 14 “NutriMat” the use of harvested Mytilus edulis, originally settling in vast amounts on the foundations of offshore wind farms, was investigated (Weiss et al. 2012). The removal of fouling organisms at regular intervals due to regulated construction surveys is mandatory to get an insight into corrosion, cuts or any other potential damage on the wind turbine foundation surface. However, the inspection and resulting removal opens an access to a high quality protein and lipid source. The meat of harvested Blue mussels as alternative protein source in aquaculture feeds was tested for the feeding of farmed turbot (Scophthalmus maximus) (Fig. 11.12a–e). For this purpose, mussels were scraped off the foundation and transferred to the land-based facilities to produce feed in various mixtures with common fish feed and then fed to turbot, which was cultivated within a Recirculating Aquaculture System (RAS). These mixes of feed all containing different concentrations of mussel meal were tested and the resulting growth, acceptance, welfare and digestibility observed. The experiments revealed that a replacement of fish meal with mussel meal of 100% and 50% resulted in depressed growth; while a fish meal replacement with 10% and 25% of mussel meal did not reduce growth or negatively affect the health of the tested turbot. The outcome of this project was that mussel meal has a high potential to serve as supplement or fish meal replacement in feed for turbot raised in aquaculture systems and therefore reduces the impact of fisheries for fish meal production (Weiss and Buck 2017).

a–e Mussels (Mytilus edulis) from offshore foundations to be used as fish feed. a Harvested mussels scrapped from the foundation; b grinder to chop the mussel meat; c Blue mussels attached to a foundation surface underwater; d mussel meat after grinding; e mussels to be tested for parasite infestation. Photos a – b and d–e AWI/Dr. Monika Weiß; c AWI/Prof. Dr. Bela H. Buck. Modified after Weiss et al. 2012

Additionally, an automatic mussel harvesting technique by designing a remotely operating robot was developed (Fig. 11.13a–c), called EuRG (Ernte- und Reinigungsgerät, Harvest and cleaning device). It was used for harvesting mussels from the surface of the foundation. However, this vehicle was only designed on paper and never built.

a–c Harvest and cleaning device. a Side view of a foundation and an attached EuRG; the enlargement of the EuRG shows the structure in more detail; b is a computer model, which shows the load forces on the foundation and the carriage. c show some details of the development progress of the carriage and its superstructure. Modified after Weiss et al. 2012

3.2.2 Candidates: Crassostrea gigas and Ostrea edulis

Health conditions: In contrast to Blue mussel cultivation, which can rely on natural spatfall in offshore areas of the German Bight, offshore oyster cultivation depends on purchasing seed oysters and caging of animals. The biological performance of Pacific and European oysters was investigated at three different offshore sites in the German Bight during the first multi-use aquaculture project “Open Ocean Aquaculture” as well as in the project “Offshore Oyster Physiology” (OysterPhys) (Project No. 2 and No. 7, Fig. 11.1). Young oysters were cultivated in the open ocean 10–40 nautical miles off the coast in 2001–2003 and from April to October 2004 and 2007 in oyster lanterns (Fig. 11.14). Research focused on growth performance, condition and survival rates in these high-energy environments. For a higher resolution of overall condition, elemental and biochemical compositions as well as macroparasitic burden were analysed.

O. edulis and C. gigas obtained positive growth rates in terms of shell length (Fig. 11.15a) and dry mass outside their natural coastal habitat, which is normally located on the seabed of coastal seas. In general, growth rates were similar to those of oysters from nearshore coastal areas (Pogoda et al. 2011). This documents that offshore-cultivated oysters are able to achieve a “normal” or “natural” growth performance.

a-f Shell growth of the European oyster Ostrea edulis a and the Pacific oyster Crassostrea gigas b during one offshore cultivation season (mid-April—mid-October); c O. edulis and e C. gigas showing normal shell growth from offshore sites in contrast to d and f with strong shell abrasion from an exposed cultivation site where tidal currents are high. Modified after Pogoda et al. 2012. Photos AWI/Dr. Bernadette Pogoda

Furthermore, oysters developed their species-specific morphology and produced an “aesthetic” shell, which plays an important role for their market value (Matthiessen 2001) (Fig. 11.15a). Only oysters grown at sites where daily tidal currents and sediment loads are high developed a different shape (Fig. 11.15b). Thicker shells and a very compact appearance indicate that these animals strongly invested energy in shell growth to withstand the strong currents as well as to prevent shell abrasion (Newkirk et al. 1995; Pogoda et al. 2011). This emphasizes the importance of a detailed and thorough site selection prior to the start of offshore oyster cultivation or any aquaculture operation in general (see Pogoda et al. 2011).

According to typical size classes used in commercial aquaculture farms larger O. edulis spat from a Norwegian producer was used in the experiment of 2007 (Newkirk et al. 1995; Matthiessen 2001; Pogoda et al. 2011). These animals yielded significantly higher growth rates (p < 0.0001), even beyond those of Pacific oysters. The superior condition of these European oysters was reflected by an even higher condition index (Pogoda et al. 2011). Accordingly, oyster cultivation in harsh environments could benefit from using a bigger spat size class regarding physical constraints through high current velocities and wave action, as smaller animals, in a very sensitive growing phase, grow slower under severe conditions.

The European oyster showed constant increases in shell length and dry mass during the cultivation periods (Pogoda et al. 2011). This implies a high ability of dietary assimilation of the native European oyster, even when food availability is low in summer (Rick et al. 2006) and a good adaptation to this offshore environment (Newkirk et al. 1995; Matthiessen 2001; Laing et al. 2006). In contrast, seasonal variations with reduced growth rates in summer were observed for the Pacific oyster. Interestingly, this species-specific difference is also clearly reflected in parallel changes of the biochemical compositions.

The biochemical and elemental compositions were analysed to characterize the nutritional condition and for a better understanding of related energetic processes. Accumulation and depletion of metabolic energy reserves depend primarily on food quantity and quality, environmental effects on metabolic processes, and reproductive activities (Beninger and Lucas 1984; Whyte et al. 1990; Ruíz et al. 1992). Therefore, investigations focused on seasonal dynamics of the major energy storage products, namely carbohydrates, proteins and lipids, on the compositions of lipid classes and fatty acids as well as on carbon and nitrogen.

Both species utilized primarily glycogen as energy store during times of high food availability. After the phytoplankton spring bloom, when reduced growth rates were observed for C. gigas, glycogen contents were drastically depleted, whereas lipid contents increased. In contrast, O. edulis kept on growing and accumulating glycogen, while lipid contents remained relatively constant. These different strategies may be explained by the earlier maturity of Pacific oysters and the resulting conversion of carbohydrates to lipids to enhance the production of eggs, which are rich in lipid (Gallager and Mann 1986; Whyte et al. 1990; De la Parra et al. 2005).

In shellfish production, the condition index is commonly used to evaluate the effects of the surrounding environment on these organisms. It is an adequate parameter to describe the commercial quality, physiological state and health of bivalve molluscs. The most commonly applied condition index (CI) is the ratio of flesh mass to shell mass (e.g. Walne and Mann 1975; Davenport and Chen 1987). Condition indices for all three offshore-cultivated bivalve species support the positive results already observed for the growth performance at offshore sites. CI values for Blue mussels, European and Pacific oysters indicated excellent conditions (Pogoda et al. 2011).

Seasonal variations in lipid class compositions of offshore-cultivated oysters were essentially similar to those of nearshore-grown individuals (Pogoda et al. 2013). Triacylglycerols (TAG) are the main lipid stores in the investigated oysters and serve as short-term energy reserves. Together with glycogen, they accumulate during periods of high food availability and are depleted in periods of food paucity. Accordingly, the amount of TAGs is a sensitive indicator of the nutritional condition of an animal (Fraser et al. 1985). Expressed as the ratio of phospholipids to triacylglycerols (PL:TAG), values ≤1 indicate a good nutritional state (Abad et al. 1995; Caers et al. 2000) and European and Pacific oysters clearly improved condition during offshore-cultivation. PL and TAG levels reached equal proportions of 1 in summer, which indicate well-fed animals and excellent growing conditions at offshore cultivation sites in the German Bight (Pogoda et al. 2013).

Also the amount of essential fatty acids greatly affects growth and condition of oysters (Pazos et al. 1996). The fatty acid compositions of the European and the Pacific oysters were dominated by 16:0, 20:5(n − 3) and 22:6(n − 3), major components of phospholipids of typical marine organisms. Both species of offshore-cultivated oysters showed the accumulation of lipids as energy reserves during high food availability from spring to early summer. Diatom markers increased during spring and early summer in both oyster species and suggest a diet rich in diatoms (Pogoda et al. 2013). Increasingly high ratios of (n − 3)/(n − 6) during the cultivation experiment underline the excellent physiological condition of both offshore-cultivated oyster species (Pogoda et al. 2013; Pazos et al. 1996).

The combination of successful growth performance and obviously excellent overall condition of offshore-cultivated oysters resulted in insignificant mortalities. In contrast to commercial oyster production in nearshore environments, which often suffer from high mortalities, offshore survival rates for both oyster species were high (>96% in 2004, >99% in 2007) and encourage open ocean cultivation (Pogoda et al. 2011).

Parasite infestation: Studies on the macroparasite burden of offshore-cultivated European and Pacific oysters and Blue mussels reported a zero infestation at offshore locations in the North Sea (Fig. 11.16a–c). In general, parasites can affect condition and health of host animals. Buck et al. (2005), Brenner (2009) and Pogoda et al. (2012) have shown that offshore grown mussels and oysters were free of macroparasites and that infestation rates increased with proximity of the sites to shore, respectively; intertidal mussels and oysters showed the highest numbers of parasites. The debate over the effects of parasites on the energy status and overall health of the host is still open as robust data to elucidate these issues is still lacking. Three major groups of macroparasites are known to infest North Sea mussels and oysters: shell-boring polychaetes, trematodes and mytilicolid copepods. Absence of trematodes at offshore locations can be explained by their complex life cycle: they often infest intertidal gastropods as first intermediate hosts (e.g. Littorina littorea and Hydrobia ulva). These are typical macroparasites of inshore bivalves, which, however, are completely absent in offshore cultivated oysters and mussels.

Due to the absence of these exclusively coastal organisms the parasite’s life cycle cannot be completed in offshore regions (Buck et al. 2005). Mytilicolid copepods and shell-boring polychaetes (e.g. Polydora ciliata) are abundant in inshore waters (Thieltges et al. 2006). However, their short planktonic larval phase restricts successful dispersion to coastal waters. Larvae drifting away from the coast are bound to die due to predation or starvation in the absence of hosts, which are only available at very few selected offshore culture locations (Buck et al. 2005). These results present a commercial advantage of such offshore shellfish cultures.

All known micro- and macroparasites found in European coastal waters are harmless to consumers, but may have negative condition effects (macroparasites) and cause higher mortalities (microparasites) in infested hosts (Brenner et al. 2012). Beside the potential harmful effect, some macroparasites cause aesthetic risks, since they are visible due to their colour (Mytilicola intestinalis) (Fig. 11.16a) or size (Pinnotheres pisum). Oysters are commonly eaten raw and consumers would not accept the appearance of e.g. parasitic copepods, as they are easy to recognize due to their bright red colour and size (up to 25 mm). This is an issue, as it would result in a serious commercial decrease of the shellfish value. Some macroparasites could also evoke a deteriorated morphological appearance, e.g. shell-boring polychaetes. As oysters and mussels represent high-value seafood products, an aesthetic appearance of the shell—especially on the oyster half-shell market—and meat is rather important. From an economic point of view the absence of macroparasites in shellfish products is certainly favourable. Furthermore, parasite infestations could reduce harvests and severely deplete local populations. Understanding the development of infestation patterns is therefore crucial for the successful site-selection in shellfish cultivation.

Restauration and ecosystem services: Because of their high ecological value oyster stocks are now in the focus of European conservation efforts. In the context of cooperation within the Oslo-Paris Commission (OSPAR), the native oyster was identified as a severely endangered habitat creating species and its protection in its area of distribution was concluded. According to the Habitats Directive for the protected habitat type “reef”, a favourable conservation status has to be preserved or restored. In view of the ecosystem-related benefits of oyster reefs, especially the high biodiversity of species found in reefs, the Federal Agency for Nature Conservation (BfN) is engaged with the possibilities of a potential reintroduction of native European oysters in the North Sea. The recently launched Project No. 16 “Restore” aims at the development of strategies for a sustainable restoration of Ostrea edulis in the German Bight. Methods and procedures will be tested at experimental scales at different locations in the field. As fishery is completely prohibited within offshore wind farm areas in German waters, these are in the focus for first restoration sites and resemble yet another type of multi-use. Results of this investigation will support the future development and implementation of a German native oyster restoration program to re-establish a healthy population of this highly endangered oyster species in the German North Sea.

3.3 Crustacean Species

3.3.1 Candidate: Homarus gammarus

Krone and Schröder (2011) and Krone et al. (2013) investigated various artificial reefs (e.g. wind farms, wrecks) to proof if these new hard substrate structures, which are placed on the sand and silt dominated seabed of the German Bight, would provide a habitat for a hard bottom dweller like the European lobster. From these insights Krone (2012a) developed various habitat designs connected to foundations of offshore wind foundations, which allow mobile reef fauna, such as lobsters, to live in or hide. These new designs could be beneficial to reef fauna stocks.

The population of the European lobster H. gammarus in the German Bight is currently limited to the rocky area around the island of Helgoland. Despite management and reinforcement actions, the lobster population has still not recovered from a severe collapse in the 1950s and 1960s (Schmalenbach et al. 2011). A successful settlement of the animals in the stone fields that surround the individual wind turbines, could possibly contribute to the long-term stabilization of the population. Researchers are now exposing lobsters in this emerging habitat (Schmalenbach and Krone 2011). The project will investigate the feasibility and environmental consequences of such a lobster transaction. 2,400 animals were raised in a rearing facility on Helgoland in 2013/2014. Young lobsters, about five cm size, were then relocated by divers to the hard substrate surrounding wind turbines in the Borkum Riffgat offshore wind farm 70 km off the German-Dutch coast. Researchers will survey the ecological habitat and how many of the juveniles settle successfully in the stone fields (Krone et al. 2013).

The shown foundation has climbing aids in the form of guide profiles, which are fastened in some sections to the offshore construction in a vertical, horizontal, and/or diagonal direction (Fig. 11.17a–c). These profiles are designed as rib-shaped flat or round profiles as well as structured by flat transverse profiles, which are also used for making breeding places (Krone et al. 2012). The pyramid-like structure (polyhedral form) relates to an artificial habitat to crustaceans on soft bottoms (Fig. 11.17d; Krone 2012b). Lobsters and other crustaceans as basically hard substrate animals also settle on soft soils when suitable habitats are available. This device can be placed next to wind turbine foundations. Another device is a scavenging carriage including a basic unit and a running unit that is configured to detachably couple the scavenging carriage with a rail device to be movable. The scavenging carriage is configured to detachably couple with the habitat carriage and the lifting device (Fig. 11.17e; Krone and Krämer (2011). Finally, one more device was invented to be used to establish and harvest a colony of benthic animals, in particular crabs. The device is hoisted and lowered in the folded form, and is laid out in the folded or fully open form. Tubular components improve drift and are particularly attractive as a habitat for crabs. This device can be used as an artificial reef to establish a colony and as a trap for effectively harvesting crabs in the immediate surroundings of wind turbines in offshore areas (Fig. 11.17f; Krone and Krämer (2012).

a–d Wind farm foundations as artificial reefs. a shows a tripod foundation with climbing aids; b are potential guide profiles for the target species in a flat, round or even structured mode; c profiles attached to a foundation piece in a circular and spiral manner; d artificial habitat in polyhedron form for crustaceans; e scavenging carriage to harvest target species; f device for colonizing and harvesting marine hardground animals (all images modified after Krone (2012a); Krone et al. 2012; Krone and Krämer (2012) and Krone and Krämer (2011)

3.3.2 Candidate: Cancer pagurus

The edible crab or brown crab is a potential candidate for multi-use by passive gear fishery within offshore wind farms (OWF). As this species covers fairly the same niche as the European lobster and is also a high value seafood product on the market, it is another promising candidate that should be examined. Passive fishery on brown crab is very common along Northern European coasts and also in several offshore areas of the German Bight and reduces the ecological pressure on the endangered lobster population. Clear positive effects on the potential of OWFs to function as refuge for fish and marine animals were observed for crustacean species such as brown crab (Cancer pagurus) due to increased opportunities for shelter and food availability (Stelzenmüller et al. 2016).

3.4 Fish Species

Fish as a candidate for offshore multi-use concepts is new. Most of the studies on aquaculture in offshore wind farms concentrated on invertebrates and algae. In recent years, interest in offshore fish cultivation is increasing (Buck and Krause 2012). By now, only few studies focused on culture techniques, system design as well as on the commercial potential and the management of fish cultivation in wind farms (Buck et al. 2012). Existing studies on the biology of offshore fish cultivation, however, did not directly deal with fish cultivation in co-use with wind farms. Hundt et al. (2011) and Buck et al. (2012) provided a list of potential candidates for the cultivation in wind farms in the EEZ of the German Bight, such as European sea bass (Dicentrarchus labrax), cod (Gadus morhua), Atlantic halibut (Hippoglossus hippoglossus), turbot (Scophthalmus maximus), haddock (Melanogrammus aeglefinus), and Atlantic salmon (Salmo salar).

This selection of candidate species for offshore aquaculture in the German Bight was based on mainly four criteria: (1) natural occurrence in the North Sea (absolutely no introduction of non-native species), (2) physical requirements of candidates match the conditions in the German Bight, (3) current status of farming knowledge and available techniques, and (4) its economic feasibility (Buck et al. 2012). Generally, the harsh offshore conditions of the North Sea, namely strong tidal currents and wave heights, and the wide temperature difference in the shallow marginal sea limit the candidate list to few fish species. For the German Bight, the strong temperature difference lies between <6 °C in winter and >21 °C in summer and is probably the most limiting factor for cultivation of many fish species (Buck et al. 2012). Furthermore, Buck et al. (2012) conducted studies on the welfare of fish within net pens in RAS conditions that were similar to exposed conditions offshore. These results demonstrated, that a clear understanding of the dependence of fish fitness on strong hydrodynamic conditions is paramount.

3.4.1 Candidate: Dicentrarchus labrax

The European sea bass is a well-established species in aquaculture and with a production of over 60,000 tons per year one of Europe’s most cultured marine fish species (FAO 2005). The on-growing usually takes place in coastal surface cages (FAO 2005), but the successful rearing under more exposed conditions was proven in flexible surface cages in the Mediterranean (Sturrock et al. 2008), which is the main site of production of European sea bass. Since sea bass is a physoclist species, in which the swim bladder is closed and pressure compensation is only possible by slow gas exchange, the ascent and decent of the cage has to include sufficient breaks to prevent a barotrauma of the fish’s swim bladder (Korsøen 2011). However, the eurythermal species is capable to tolerate temperatures below 5 °C (FAO 2005), which would enable on-growing in the offshore regions of the German North Sea. Nonetheless, the average temperature of 10 °C in the North Sea (Wiltshire and Manly 2004) is below its optimum temperature range of 22–28 °C for growth (Lanari et al. 2002), which will result in an extended on-growing phase. A rough approximation of the actual length at the end of the on-growing can be based on the growth models by Lanari et al. (2002) and the annual temperature of the water in the German Bight (data BSH-German station bay, 10 m depth, daily mean values of 2009, www.bsh.de). The model suggests that an approximately 3 g fingerling would need 31 months to reach the 300 g harvest weight (Buck et al. 2012). This exceeds the production of D. labrax in cages in the Mediterranean by 4–8 months (FAO 2005) making an offshore cultivation in the North Sea economically not feasible.

During a subproject of Project No. 13 “Open Ocean Multi-Use”, the welfare of European seabass was tested by exposing fish in a tank device to loud noise using underwater speakers (Fig. 11.18a) (Fiedler et al. 2011). The noise was equivalent to the sound, which originated from offshore wind turbines in 2 m depth of the surrounding water column. Next to welfare observation and the fish behaviour regarding acceptance of feed, excitability, escape, aggression among fish of the stock as well as taking cholesterol samples to measure stress were conducted. Interestingly, fish did accept the loud noise in short time of 1–2 days. After adaption of the noise the fish showed no abnormal behaviour as well as cholesterol concentrations was within a threshold of fish not exposed to the noise.

a–c European seabass (Dicentrarchus labrax) and turbot (Scophthalmus maximus) for welfare experiments. a Sea bass in a tank of a recirculating system with speakers at the side wall of the tank to induce noises imitated of offshore wind turbines; b Juvenile turbots swimming in a cylinder-like cage model with a current velocity of 0.5 m/s to test welfare and behaviour and c in a current velocity of 0.9 m/s. Photos a University of Applied Sciences Bremerhaven/Gerrit Fiedler modified after Fiedler et al. 2011, b–c AWI/Jan Schmidt and Tim Heusinger modified after Buck et al. 2012

However, at this stage it is important to understand that this test was just a preliminary work, which has to be conducted again in full scale, which means: more replicates, better infrastructure and experienced personal. The presented work was conducted during a student’s project with limited access to specific infrastructure and financial support. Nevertheless, even if not planned under best conditions, the work shows a trend, which requires more research on this topic.

3.4.2 Candidate: Gadus morhua

Declining catches of Atlantic cod lead to a growing interest in aquaculture of this species. For more than thirty years, the intensive production of cod has been established (Moksness et al. 2004). The rearing of G. morhua requires the production of live food of different sizes and feeding protocols need to be followed strictly (Moksness et al. 2004). Of all the gadoid species, cod is thought to have the greatest potential for future development for aquaculture and some scientists believe that within the next 20 years similarly high production levels can be achieved as for the Atlantic salmon (Rosenlund and Skretting 2006). The suitability of G. morhua for offshore aquaculture has been successfully demonstrated in 3000 m3 submersible cages including automatic feeding buoys by the company Sea Station™ off the coast of New Hampshire (Chambers and Howell 2006). As G. morhua is a physoclist species, necessary pauses need to be included during vertical movements of the cage (Korsøen 2011). One major problem for cod aquaculture is their ability to bite through the mesh or other materials, which makes them the fish species with the highest escapee rate (Jensen et al. 2010), which could have a negative impact on wild population by cross-breeding (Davies et al. 2008). The extreme temperature tolerance range from −1 to 23 °C and an optimum temperature range from 8 to 12 °C (Jobling 1988) make this species a candidate for aquaculture in the German Bight. However, aquaculture companies should be aware that the relatively high summer temperatures in the German Bight could enhance the risk of infections, as G. morhua is prone to bacterial fish pathogens such as Franciscella spec. or Aeromonas salmonicidae at prolonged temperatures of more than 12 °C (Buck et al. 2012).

3.4.3 Candidate: Hippoglossus hippoglossus

The Atlantic halibut is a much valued aquaculture candidate as the species is resistant to several common fish diseases, has high food conversion efficiency and a good meat quality due to its firm texture and long shelf life (Daniels and Watanabe 2010). However, the rearing of fingerlings is difficult as larvae need the right composition of live feed after the yolk sac stage and a precise temperature regime. The on-growing of H. hippoglossus takes place either in land-based tanks or troughs, or in net cages in the sea (Daniels and Watanabe 2010). The use of submersible cages was successfully demonstrated for halibut (Howell and Chambers 2005; Daniels and Watanabe 2010), offering significant advantages in contrast to surface culture, such as avoidance of the exposure to the seasonal high water temperatures and to the effect of UV radiation at the surface. The temperature tolerance range for the Atlantic halibut reaches from −1.3 to approximately 18–20 °C, depending on the oxygen saturation of the water (Daniels and Watanabe 2010). Although the oxygen saturation in the German Bight is very high below 10 m depth, temperatures in extreme years can reach values outside of the physiological capacity of H. hippoglossus. Furthermore, Atlantic halibut is sensitive to strong currents and turbidity (Buck et al. 2012). For offshore site selection, it is important to identify an area with a sufficient supply of oxygen, a moderate temperature regime as well as low current flow and turbidity.

3.4.4 Candidate: Scophthalmus maximus

The turbot is one of the most valuable food fish of the North-East Atlantic. Since the 1990s, intensive production methods are established for all stages of life of this species (Moksness et al. 2004). Today, the on-growing of turbot takes place mainly in land-based recirculating aquaculture systems. S. maximus can be held in very high stocking densities at optimum parameters (Daniels and Watanabe 2010). The culture in surface cages, or submersible cages, was successfully demonstrated at moderate velocities and a constant temperature regime (Daniels and Watanabe 2010). Since the growth of turbot rapidly decreases below 14 °C and above 20 °C and it stops feeding below 8 °C and above 22 °C, the temperature conditions in the German-Bight do not favour on-growing year-round (Person-Le Ruyet et al. 2006; Daniels and Watanabe 2010). In addition, this species is sensitive to the tide flow rates of up to 1.2 ms−1 (Buck 2002), which plays an important role for site selection in the German Bight (Buck et al. 2012).

Taking the results of current velocities and waves on cages and the nets (see Sect. 11.4 “Technologies” below) into account a further test was conducted to proof the behaviour of the culture candidates living in these high energy environments. These tests were conducted at the ZAF (Zentrum für Aquakulturforschung/Center for Aquaculture Research) under the umbrella of the AWI. A cage prototype (Fig. 11.18b, c) was manufactured and installed in a large raceway of a RAS (Recirculating Aquaculture System) including a water treatment device (drum filter, nitrifying and denitrifying filter, and protein skimmer) to guarantee best water quality during the experiment. This cylindrical cage (see section above) was mounted in a way that an adjustable pump (Hydor Koralia magnum 5, flow rate 6,500 l/h) induced a certain current velocity on the cage and its inner culture space. The cylinder cage in a size of 1:40 was taken from the current flume/wave tank investigations in Hanover.

The challenge in the subproject of Project No. 13 “Open Ocean Multi-Use” was to find fish species in small size to be used as model organism, such as juvenile turbots with a mean size of approx. 10 g (Scophthalmus maximus) (Buck et al. 2012). This fish size of the “model organism” would in terms of scaling correspond to a market sized adult turbot, which would be farmed in real offshore cages.

After acclimatizing the fish in the cage model after several hours the pump was switched on for a short term to induce a current velocity of 0.9 ms-1 at the exhaust pipe. The pump was adjustable in the tank so that the distance to the cage could be within a range of 25–150 cm. This distance to the cage and the resulting current velocity was calculated by using a corresponding situation as it occurs at the offshore site. After starting the experiment fish behaviour, escape response, welfare, and reaction at feeding were recorded using an underwater video camera.

The results of these investigations show a strong impact of strong current velocities on farmed turbot within the cage. Juvenile turbot are unharmed at velocities of 0–1.0 ms-1. However, the fish are affected by stronger currents in a way that the fish will be transferred from their resting area on the bottom of the cage resulting in more activity of the fish swimming against the current trying to resettle on the bottom. At very strong current velocities of 1.5 ms-1 and higher it might happen that young turbots are pressed against the net of the cage leading to the risk to obtain skin injuries.

To summarize, these results show that turbot cultivation offshore is not suitable if current velocities exceed a certain value, making a site-selection-criteria process necessary. However, we have to take into account that we used small fish—the model organism—in the experiment, which allowed the upscaling to a size corresponding with real fish sizes to be farmed at offshore sites. As fish in a size we used in this investigation will never be transferred to offshore sites as it is described in this book we assume that larger fish, which normally will be cultured in offshore cages, will act differently.

3.4.5 Candidate: Melanogrammus aeglefinus

The haddock is a valued food fish on both sides of the North Atlantic, but its wild catches stagnate, so that haddock is an interesting candidate for aquaculture (Moksness et al. 2004). In recent years, the cooperation of a large commercial salmon production (Heritage Salmon Limited) with various Canadian research institutes lead to great advances in the management of broodstock, the feed of larvae, as well as the weaning and on-growing methods (Chambers and Howell 2006). Same as cod, haddock is a physoclist species and breaks in descents and ascents need to be included to prevent barotraumas due to rapid pressure changes by vertical movement of the cages. (Buck et al. 2012). Moreover, M. aeglefinus has the ability to penetrate even tight mesh (Özbilgina and Glass 2004), precaution needs to be taken to prevent escapes. The on-growing of M. aeglefinus in submersible offshore cages has proven to be very promising, reaching good growth rates in a 600 m2 Sea Station at the temperature conditions off the coast of New Hampshire (Chambers and Howell 2006). However, the similarly high growth rates as cod in the first year decreased slightly and the growth potential over longer periods of time must be considered to be lower than in cod (Treasurer et al. 2006). Haddock can tolerate temperatures between 1 and 20 °C (Chambers and Howell 2006), making it a potential aquaculture species for the offshore area in the German Bight.

3.4.6 Candidate: Salmo salar

With an annual production of 1,244,637 t (Bilio 2008), the Atlantic salmon, Salmo salar, is by far the most produced marine species. Although S. salar is an anadromous species, which is spending a part of its live in freshwater (FAO 2004), it is an excellent candidate for aquaculture in marine waters and has its highest growth rate at salinities between 33 and 34‰. The temperature range for this species is 6–16 °C (FAO 2004), with temperatures optimal for growth between 8 and 12 °C (Boghen 1991). Although the temperature minima and maxima of this species can be exceeded in the surface waters of German North Sea, the Atlantic salmon is thought to be suitable for aquaculture in the German Bight (Buck et al. 2012).

3.5 Various Species in One Habitat—Managing Reef Effects

Following Krone (2012b), it is currently difficult to judge the ecological consequences associated with the introduction of the artificial reef type “wind power foundation” and its reef effects on fish and benthos. The question whether the impact is positive, negative or negligible remains unanswered and depends on the emphasis one places on the different implications of the reef effect. The present findings, however, enable the designed structure to increase or to reduce biofouling and megafauna settlement at offshore wind power foundations (Fig. 11.19). Krone (2012b) defines it as “reef passivation”. Alternatively, all potential reef functions could be activated if the development of a highly valuable artificial reef fauna is intended, such as “reef activation” (for more details see Krone 2012b).

Techniques for passivation and activation of wind power foundations and artificial reef fauna examples. 1 Electrochemical anti-fouling system for structures wetted by sea water; 2 Calcareous EAT-material designed to reduce structural diversity and as scour protection; 3 Device for using technical devices underwater, equipped with a camera; 4 The electrochemical anti-fouling system applied to prevent sea stars (A. rubens) to climb up to feed on the Bivalvia M. edulis; 5 Device for developing habitats in the underwater area of an offshore construction, paths and hideouts for crabs and demersal fish; 6 EAT-material used to create reef-like structures to enhance the reef species; 7 Device for colonizing and harvesting marine hard ground animalssuch as M. edulis and large vagile megafauna; 8 Transportable device for colonizing and harvesting invertebrates in the vicinity of offshore constructions; 9 Artificial habitat in polyhedron shape used as a fishing net barrier which is at the same time habitable for lobsters (modified after Krone 2012b)

4 Technology

4.1 Longline-Techniques and Combination to Wind Farm Turbines

In the coastal sea of Germany, there are some limitations to allow the expansion of mussel culture activities. First, nearly 98% of the coastal sea has a nature reserve status. Culture plot sizes are decreasing in order to follow the mussel management plans of Schleswig-Holstein and Lower-Saxony (e.g. CWSS 2002; Buck 2002) with no new licenses being approved in the future. Second, moving more seawards to abandon the preserved areas, environmental conditions in the North Sea are harsh and protected bays for safe mussel longline cultivation is inexistent. However, exposed locations off the coast are in the focus for many aquaculture activities worldwide (e.g. Polk 1996; Hesley 1997; Stickney 1998; Bridger and Costa-Pierce 2003) and generated a vast quantity of projects in high energy environments. With this in mind, a multiple use concept for another newcomer, the offshore wind farm operator, has been developed (Buck et al. 2004). The offshore wind farm turbines provide space and attachment devices for mariculture installations and therefore minimize the risks originating from high energy environments (Buck et al. 2006b). The viability of a mussel cultivation enterprise within offshore wind farm areas was intensively studied following various factors, such as (1) the technological and biological feasibility, (2) the legislative and regulatory constraints, (3) the environmental sustainability of farming aquatic organisms at all, and (4) the profitability of this potential commercial operation (for review see Buck et al. 2008a). However, without the solid foundations of the wind turbines as anchor or connection points, economic viable installations of equipment for an extensive mariculture would decrease in view of the high-energy environment in this part of the North Sea.

4.1.1 Mussel Longlines: Design

In Project No. 3 (Roter Sand) different anchored longlines were installed in order to test their suitability under open sea conditions in terms of material and functionality and to obtain insights on how to connect these systems to wind farm foundations. Various test devices of horizontal ropes anchored to the seafloor with buoys to provide flotation and vertical droppers for spat collection and/or mussel grow-out were deployed offshore in multi-use with the wind farm “Energiekontor” 17 nautical miles off Bremerhaven.