Abstract

Bayer process of alumina production involves generation of considerable mud tonnage (1.5 – 3 t of red mud per 1 ton of alumina) with high content of scandium and rare earth metals up to 120 g/t and 1500 g/t respectively. Scandium is difficult-to-obtain and expensive element (oxide price – 99.9–99.99% is between USD 4 000 – 5000 per kg). The main applications are the high quality alloys, high temperature ceramics, luminescent materials, dielectrics.

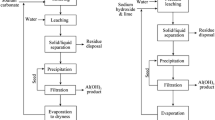

In frames of creation of ecologically friendly technology to utilize red mud, RUSAL is developing process of scandium concentrate recovery based on the carbonization leaching of scandium. This process allows improvement of the efficiency of red mud processing by scandium recovery and partial caustic removal with alkali recycling to the process. This technology excludes the acids effluents and can be easily implemented into existing process circuit. This paper presents the results of the laboratory trials of red mud processing with scandium concentrate generation, as well as the data on the pilot unit to produce scandium concentrate at one of the alumina refineries in Russia.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

6. References

Methodical directions Aluminum alloys in production of details of mechanisms and machines A.E. Artes, Moscow, 2004, MGTU «Stankin».

Jiang Feng, Bai Lan, Yin Zhimin Preparation of Scandium-Bearing Master Alloys by Aluminium-Magnesium Thermoreduction. Journal of rare earths, 2002, V. 20, № 5, p. 507–511.

V.V. Zaharov, V.I. Elagin, T.D. Rostova, Y.A. Filatov Physicometallurgical principles of aluminum alloys alloyage by scandium, 2010 № 1, p. 67

N. Trofimenko, M. Kuznezoff, A. Michaelis Electrochemical Characterization of High Temperature Solid Oxide Electrolysis Cell Based on Scandia Stabilized Zirconia with Enhanced Electrode Performance, 10-th EUROPEAN SOFC FORUM 2012, 26–29 June 2012, Lucerne, Switzerland, P. 0703.

Курицына И.Е., Бредихин С.И., Коровкин Е.В., Синицын В.В. Сравнительное исследование транспортных и механических характеристик твердого электролита ZrO2, допированного скандием, Всероссийская конференция с международным участием «Твердооксидные топливные элементы и энергоустановки на их основе», 16–18 июня 2010, Черноголовка, Россия, С. 80–83.

Scandium Korshunov B.G., Reznik A.M., Semenov S.A., Moscow: Metallurgy, 1987, 164 p.

Scandium in bauxites and clays. / V.N. Lavrenchuk, A.V. Stryapkov, E.N. Kokovin; GUP SO Kamensk-Uralsk Printshop, 2004. – 291 pages.

A.B. Kozyrev, A.V. Nechaev, A.S. Sibilev, G.N. Klimentenok, O.V. Petrakova. Sorption recovery of scandium from low-concentrate raw materials — red mud / The 2nd Russian conference with international participation , ‘New approaches in chemical engineering of minerals. Application of extraction and sorption’ — St. Petersburg 2013, Russia, P 145–146.

O. Petrakova, G. Klimentenok, A. Panov, S. Gorbachev Application of modern methods for red mud processing to produce rare earth elements, 1st European Rare Earth Resources Conference, 4–7 September, Milos, Greece, P. 221–229.

Inorganic and analytical scandium chemistry, L.N. Komissarova, Moscow, 2001, Editorial URSS, P 512.

Patent 2483131 Russia. Method for scandium production from red mud / I.N. Pyagay, S.P. Yatsenko, L.A. Pasechnik, and others; Published 27.05.2013, Bulletin No 15.

V.S. Anashkin, S.E. Vishnyakov, O.V. Petrakova, S.N. Gorbachev, A.V. Panov Method for scandium concentrate production from red mud. Russian Federation patent application № 2014121942 from 29.05.2014.

Rare earth metals carbonates: Review information Moscow: “Tsvetmetinformatsiya”, 1990. 50 p.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Petrakova, O.V. et al. (2015). Improved Efficiency of Red Mud Processing through Scandium Oxide Recovery. In: Hyland, M. (eds) Light Metals 2015. Springer, Cham. https://doi.org/10.1007/978-3-319-48248-4_17

Download citation

DOI: https://doi.org/10.1007/978-3-319-48248-4_17

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48610-9

Online ISBN: 978-3-319-48248-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)