Abstract

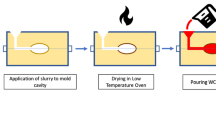

This chapter presents the issue of the effect of technological parameters (impact on the cooling rate and the physicochemical state of liquid metal) on the microstructure and quality of the casting surface. A diagram of the impact of the technological factors on the parameters of the microstructure of cast iron SGI and CGI is presented. It is demonstrated that wall thickness of the casting and pouring temperature affect the initial temperature of the metal in the mold, which determines the thickness and the presence of flake graphite in the surface layer. Moreover, the issues is raised dealing with chemical composition, including despheroidising elements, metallurgical treatments, as well as changes in the cooling rate at the transition from conventional through thin up to the ultra-thin wall casting s in terms of shaping defects and the casting surface. In addition to this, molding sand is also considered in this chapter. Special attention is paid to the molding sands containing reclaimed resin-bonded sand with p-toluenosulfonic acid as a hardening catalyst. Finally, a comparison between the effects of different types of molding sands with using fresh and reclaimed materials, protection atmosphere and coatings is shown.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Fraś E, Górny M, Lopez HF (2007) Eutectic cell and nodule count in grey and nodular cast irons. Mater Sci Tech 23(9):1109–1117

Fraś E, Górny M, Kapturkiewicz W, Lopez HF (2008) Chilling tendency and chill of cast iron. Tsinghua Sci Technol 13(2):177–183

Fraś E (2003) Solidification of alloys, WNT, Warszawa

Górny M, Dańko R, Holtzer M (2015) The effects of the metal temperature and wall thickness on flake graphite layer in ductile iron. Metalurgija 54(1):11–14

Boonmee S (2013) Ductile and compacted graphite iron casting skin—evaluation, effect on fatigue strength and elimination. PhD Dissertation, The Ohio State University (https://etd.ohiolink.edu/!etd.send_file?accession=osu1364310320&disposition=inline)

Sergeant GF, Evans ER (1978) The production and properties of compacted graphite irons. Br Foundryman 71:115

Marti F, Karsay SI (1979) Localized flake graphite structure as a result of a reaction between molten ductile iron and some components of the mold. AFS Trans 87:221–226

Nechtelberger E, Puhr H, van Nesselrode JB, Nakayasu A (1982) Cast iron with vermicular/compacted graphite-state of the art. In: International Foundry Congress, Chicago, pp 1–39

Goodrich G, Lobenhofer R (2002) Effect of cooling rate on ductile iron mechanical properties. AFS Trans 110:1003–1032

Duncan FC, Kroker J (2010) A new test casting to evaluate skin formation in CGI. AFS Trans 118:10–023

Javaid A, Davis KG, Sahoo M (1999) Effect of chemistry and processing variables on the mechanical properties of thin wall ductile iron castings. Materials Technology Laboratory Report MTL

Borrajo JM, Martinez RA, Boeri RE, Sikora JA (2002) Shape and count of free graphite particles in thin wall ductile iron castings. ISIJ Int 42(3):257–263

Stefanescu DM (2005) Metal handbook, properties and selection: irons, steels and high-performance alloys, vol 1. ASM International, Russell

Górny M (2010) Structure formation of ultra-thin wall ductile iron castings. Akapit, Cracow

Ivan N, Chisamera M, Riposan I (2012) Mold coatings to reduce graphite degeneration in the surface layer of ductile iron castings. Int J Metal Cast, 61–70

Dańko R, Holtzer M, Górny M, Żymankowska-Kumon S (2013) Effect of reclamation on the skin layer of ductile iron cast in furan molds. J Mat Eng Perform 22(11):3592–3600

Dańko R, Holtzer M, Górny M, Żymankowska-Kumon S (2014) Effect of the quality of furan moulding sand on the skin layer of ductile iron castings. ISIJ Int 54(6):1288–1293

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2015 The Author(s)

About this chapter

Cite this chapter

Górny, M. (2015). Influence of the Technological Parameters on the Microstructure and Quality of the Casting Surface. In: Microstructure and Properties of Ductile Iron and Compacted Graphite Iron Castings. SpringerBriefs in Materials. Springer, Cham. https://doi.org/10.1007/978-3-319-14583-9_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-14583-9_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-14582-2

Online ISBN: 978-3-319-14583-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)