Abstract

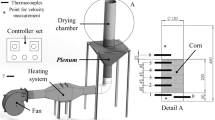

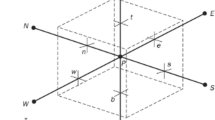

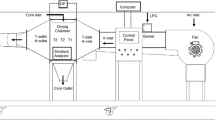

This chapter focuses in drying of wet solids in cross flow dryer (continuous drying system) with particular reference to grains. Here, topics related to grain, drying fundamental, types and selection of dryer, and drying models are presented in details. A cross flow dryer mathematical modeling that considers the influence of the porosity of the bed and transient terms in the drying process is presented and discussed. The governing conservation equations have been solved numerically using the finite-volume method and upwind formulation to convective terms. Application has been done to drying of yellow corn kernel. To analyze the influence of the main drying parameters on the quality of the product at the end of the process, results of the humidity ratio and temperature of the air and temperature and moisture content of the solid along of the drying process are presented, analyzed and compared with experimental data.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Brokker, D.B., Bakker-Arkena, F.W., Hall, C.W.: Drying and Storage of Grains and Oil Seeds. AV1 Book, New York (1992)

Rumsey, T.R., Rovedo, C.O.: Two-dimensional simulation model for dynamic cross-flow rice drying. Chem. Eng. Process. 40, 355–362 (2001)

Pang, S., Haslett, A.N.: High-temperature kiln drying of softwood timber: the role of mathematical modeling. In: Turner, I., Mujumdar, A.S. (eds.) Mathematical Modeling and Numerical Techniques in Drying Technology. Marcel Dekker Inc, New York (1997)

Houška, K., Valchář, J., Viktorin, Z.: Computer-aided design of dryers. In: Mujumdar, A.S. (ed.) Advances in Drying, vol. 4. Hemisphere Publishing Corporation, New York (1987)

Sokhansanj, S.: Grain drying simulation with respect to energy conservation and grain quality. In: Mujumdar, A.S. (ed.) Advances in Drying, vol. 3. Hemisphere Publishing Corporation, New York (1984)

Imre, L.: Solar drying. In: Mujumdar, A.S. (ed.) Handbook of Industrial Drying, vol. 1. Marcel Dekker, Inc., New York (1995)

Turner, I., Perré, P.: A synopsis of the strategies and efficient resolution techniques used for modelling and numerically simulating the drying process. In: Turner, I., Mujumdar, A.S. (eds.) Mathematical Modeling and Numerical Techniques in Drying Technology. Marcel Dekker, Inc., New York (1997)

Bakker-Arkema, F.W., Lerew, L.E., De Boer, S.F., Roth, M.C.: Grain drying simulation, Reseacher Report 224 (1974)

Sokhansanj, S., Wood, H.C.: Simulation of thermal and disinfestations characteristics of forage dryer. Drying Technol. 9(3), 643–656 (1991)

Fasina, O., Sokhansang, S.: Modeling the bulk cooling of alfalfa pellets. Drying Technol. 13(889), 1881–1904 (1993)

Barrozo, M.A.S., Sartori, D.J.M., Freire, J.T.: Simultaneous heat and mass transfer during the drying of the soybeans seeds in a crossflow moving bed. In: Proceeding of the International Drying Symposium (IDS), Krakow, Poland, vol. B, pp. 873–880, (1996)

Motta-Lima, O.C., Pinto, J.C., Massarani, G.: Parameter estimation in cross-flow sliding bed drying. In: Proceedings of the International Drying Symposium, Krakow, Poland, vol. A, pp. 283–290, (1996)

Li, Y., Cao, C., Liu, D.: Simulation of recirculating circular grain dryer with tempering stage. Drying Technol. 15(1), 201–214 (1997)

Liu, Q., Bakker-Arkema, F.W.: Automatic control of cross-flow dryers, part 2: design of a model-predictive controller. J. Agric. Eng. Res. 80(2), 173–181 (2001)

Liu, Q., Bakker-Arkema, F.W.: Automatic control of cross-flow dryers, part 1: development of process model. J. Agric. Eng. Res. 80(1), 81–86 (2001)

Eltigani, A.Y., Bakker-Arkena, F.W.: Automatic control of commercial cross-flow grain dryers. Drying Technol. 5(4), 561–575 (1987)

Vasconcelos, L.G.S., Alsina, O.L.S.: Drying simulation of (carioca( beans in cross-flow. In: Proceedings of the International Drying Symposium (IDS), Montreal, Canada, vol. B, pp. 1500–1507, (1992)

França, A.S., Fortes, M., Haghighi, K.: Numerical simulation of intermittent and continuous deep-bed drying of biological material. Drying Technol. 12(7), 1537–1560 (1994)

Soponronnarit, S., Prachaayawarakorn, S., Sripawatakul, O.: Developments of cross-flow fluidized bed paddy dryer. Drying Technol. 14(10), 2397–2410 (1996)

Giner, S.A., Mascheroni, R.H., Wellist, M.E.: Cross-flow drying of wheat: a simulation program with a diffusion-based deep-bed model and a kinetic equation for viability loss estimation. Drying Technol. 14(10), 2255–2292 (1996)

Giner, S.A., Bruce, D.M., Mortimore, S.: Two-dimensional model of steady-state mixed-flow grain drying: part 1: the model. J. Agric. Eng. Res. 71, 37–50 (1998)

Giner, S.A., Bruce, D.M.: Two-dimensional model of steady-state mixed-flow grain drying: part 2: experimental validation. J. Agric. Eng. Res. 71, 51–56 (1998)

Santori, D.J.M.: Drying of reeds in cross-flow moving bed: mechanical effect and air humidity. In: Proceedings of the International Drying Symposium (IDS), Montreal, Canada, vol. B, pp. 1524–1533, (1992)

Pimentel, R.O., Sartori, D.J.M.: Drying of grass seeds in cross flow band dryer. In Proceedings of the International Drying Symposium, Halkidiki, Greece, vol. B, pp. 1350–1357 (1998)

Yang, W., Siebenmorgen, T.J., Jia, C.C., Howwell, T.A., Cnossen, A.G.: Cross-Flow drying of rough rice as mapped on its glass transition state diagram. In: Proceedings of the International Drying Symposium (IDS), Noordwijkerhout, The Netherlands, CD ROM (2000)

Siebenmorgen, W.Y., Jia, C.C., Howell, T.A., Cuossen, A.G.: Cross-flow drying of rough rice as mapped and its glass transition state diagram. In: Proceedings of the International Drying Symposium (IDS), Noordwijkerhout, The Netherlands, CD ROM (2000)

Farias, R.P.: Biological products drying simulation in crossflow dryer. Master Thesis (Mechanical Engineering), Federal University of Campina Grande, Campina Grande, Brazil (2003). (In portuguese)

Farias, R.P., Holanda, P.R.H., Lima, A.G.B.: Drying of grains in conveyor dryer and cross flow: a numerical solution using finite-volume method. Braz. J. Agro-ind. Prod. 6(1), 1–16 (2004)

Fick, A.: Ueber diffusion. Annln Phys. 170(1), 59–86 (1855)

Sun-Tak, Hwang, Kammermeyer, K.: Membranes in Separations. Wiley, New York (1975)

Shukla, K.N.: Diffusion Processes During Drying of Solids. World Scientific, Singapore (1990)

Lewis, W.K.: The rate of drying of solid materials. J. Ind. Eng. Chem. 13, 427–432 (1921)

Sherwood, T.K.: The drying of solid, Pt. I. Ind. Eng. Chem. 21, 12–16 (1929)

Sherwood, T.K.: The drying of solids, Pt. II. Ind. Eng. Chem. 21, 976–980 (1929)

Sherwood, T.K.: The drying of solids, Pt. III, Mechanism of the drying of pulp and paper. Ind. Eng. Chem. 22, 132–136 (1930)

Newman, A.B.: Diffusion and surface emission equation. Trans. AIChe. 27, 203–220 (1931)

Fortes, M., Okos, M.R.: Drying theories: their bases and limitations as applied to foods and grains. In: Mujumdar, A.S. (ed.) Advances in Drying, vol. 1. Hemisphere Publishing Corporation, Washington (1980)

Parry, J.L.: Mathematical modelling and computer simulation of heat and mass transfer in agricultural grain drying. A review. J. Agri. Eng. Res. 32, 1–29 (1985)

Jumah, R.Y., Mujumdar, A.S., Raghavan, G.S.V.: A mathematical model for constant and intermittent batch drying of grains in a novel rotating jet spouted bed. Drying Technol. 14(3–4), 765–802 (1996)

Rossi, S.J.: Psicrometry. João Pessoa, FUNAPE (1987). p. 60 (In Portuguese)

Patankar, S.V.: Numerical Heat Transfer and Fluid Flow. Hemisphere Publishing Corporation, New York (1980)

Maliska, C.R.: Computational Heat Transfer and Fluid Mechanics. Ed. LTC, Rio de Janeiro, Brazil (1995). (In Portuguese)

Versteeg, H.K., Malalasekera, W.: An Introduction to Computational Fluid Dynamics: The Finite Volume Method. Prentice Hall, London (1995)

Santiago, D.C., Farias, R.P., Lima, A.G.B.: Modeling and simulation of cross flow band dryer: a finite-volume approach. In: Proceedings of the International Drying Symposium (IDS), Beijing, China, CD-ROM (2002)

Fortes, M.: A non-equilibrium thermodynamics approach to transport phenomena in capillary-porous media with special reference of grain and foods. PhD Thesis, Purdue University (1978)

Acknowledgments

The authors would like to express their thanks to CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico, Brazil), CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Brazil), and FINEP (Financiadora de Estudos e Projetos, Brazil) for supporting this work; to the authors of the references in this chapter that helped in our understanding of this complex subject, and to the Editors by the opportunity given to present our research in this book.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

de Lima, A.G.B., de Farias, R.P., Farias Neto, S.R., Pereira, E.M.A., da Silva, J.V. (2014). Grain Drying Simulation: Principles, Modeling and Applications. In: Delgado, J., Barbosa de Lima, A. (eds) Transport Phenomena and Drying of Solids and Particulate Materials. Advanced Structured Materials, vol 48. Springer, Cham. https://doi.org/10.1007/978-3-319-04054-7_3

Download citation

DOI: https://doi.org/10.1007/978-3-319-04054-7_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-04053-0

Online ISBN: 978-3-319-04054-7

eBook Packages: EngineeringEngineering (R0)