Abstract

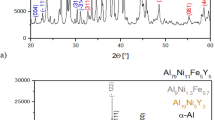

Recent studies have shown that bulk amorphous alloys from Al-based ternary systems, containing lanthanide metal and late transition metal can be fabricated. Such materials are characterized by good mechanical properties. The most common production method of these alloys is melt spinning, giving a ribbon as a final product. In order to reduce the cost of material it is possible to replace lanthanide metal by mischmetal (Mm), which is one order of magnitude cheaper than pure lanthanides. The mischmetal used in this study contains [in at.%]: Ce-50.3, La-43.5, Pr-5.9, Nd-0.3. This study had two main objectives. First — to check the possibility of replacement of yttrium in the Al-Y-Ni system alloys by mischmetal, without losing the structure and mechanical properties. The other goal was to produce the bulk amorphous material. Five alloys from Al-Mm-Ni system were investigated. The as-quenched ribbons were milled to powder and then semi-isostatically compacted at elevated temperature to bulk material. After every step of the investigation, the XRD and DSC measurements were performed to detect possible changes of structure occurring during each step of the process: ribbon production, milling, compaction. Mechanical properties were characterized by Vickers microhardness. The results of the studies show the possibility to produce bulk amorphous alloys of the above mentioned system in three-step production cycle. The microhardness is good or even better compared to Al-RE-Ni alloys. The microhardness depends not only on the chemical composition of the alloy but also on the temperature of the compaction process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Inoue, A., (1998) Prog. Mater. Sci. 43, 365–520.

Zhong, Z.C., Jiang, X.Y., and Greer, A.L., (1997) Mater. Sci. Eng. A 226–228, 531.

Zhong, Z.C., Jiang, X.Y., and Greer, A.L., (1997) Mater. Sci. Eng. A 226–228, 789.

Ohtera, K., Inoue, A., Tarabayashi, T., Nagahama, H. and Masumoto, T., (1992) Mater. Trans. JIM, 33, 775.

Kawamura, Y., Inoue, A., and Masumoto, T., (1993) Scr. Metall. 29, 25.

Latuch, J., Kokoszkiewicz, A., and Matyja, H., (1998) Mater. Sci. Forum. 269–272, 755.

Latuch, J., Dimitrov, H., Audebert, F., and Kulik, T., (2003), Solid State Phenom. 94, 71.

Dimitrov, H., Blazquez, J.S., Latuch, J., and Kulik, T., (submitted to Acta Materialia).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2005 Kluwer Academic Publishers

About this paper

Cite this paper

Kowalczyk, M., Latuch, J., Kulik, T., Dimitrov, H. (2005). Bulk Amorphous Samples from Al-Mm-Ni System. In: Idzikowski, B., Švec, P., Miglierini, M. (eds) Properties and Applications of Nanocrystalline Alloys from Amorphous Precursors. NATO Science Series, vol 184. Springer, Dordrecht. https://doi.org/10.1007/1-4020-2965-9_28

Download citation

DOI: https://doi.org/10.1007/1-4020-2965-9_28

Publisher Name: Springer, Dordrecht

Print ISBN: 978-1-4020-2963-9

Online ISBN: 978-1-4020-2965-3

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)