Abstract

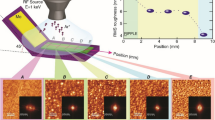

Amorphous hafnium dioxide (HfO2) film was prepared on Si (100) by facing-target mid-frequency reactive magnetron sputtering under different oxygen/argon gas ratio at room temperature with high purity Hf target. 3D surface profiler results showed that the deposition rates of HfO2 thin film under different O2/Ar gas ratio remain unchanged, indicating that the facing target midfrequency magnetron sputtering system provides effective approach to eliminate target poisoning phenomenon which is generally occurred in reactive sputtering procedure. X-ray photoelectron spectroscopy (XPS) and Fourier transform infrared spectroscopy (FTIR) demonstrated that the gradual reduction of oxygen vacancy concentration and the densification of deposited film structure with the increase of oxygen/argon (O2/Ar) gas flow ratio. Atomic force microscopy (AFM) analysis suggested that the surface of the as-deposited HfO2 thin film tends to be smoother, the root-meansquare roughness (RMS) reduced from 0.876 nm to 0.333 nm while O2/Ar gas flow ratio increased from 1/4 to 1/1. Current-Voltage measurements of MOS capacitor based on Au/HfO2/Si structure indicated that the leakage current density of HfO2 thin films decreased by increasing of oxygen partial pressure, which resulted in the variations of pore size and oxygen vacancy concentration in deposited thin films. Based on the above characterization results the leakage current mechanism for all samples was discussed systematically.

Similar content being viewed by others

References

J. Robertson, R. M. Wallace Mater. Sci. Eng. R 88, 1–41 (2015).

R. Basak, B. Maiti and A. Mallik, Superlattices Microstruct. 80, 20 (2015).

S. Capone et al., J. Vac. Sci. Technol. A 16, 3564 (1998).

J. M. Khoshman, A. Khan and M. E. Kordesch, Surf. Coat. Technol. 202, 2500 (2008).

Y. Wang, Z. Z. Yu, F. Zahid. L. Liu, Y. Zhu, J. Wang and H. Guo, J. Appl. Phys. 116, 023703 (2014).

Juan C. Ranuárez, M. J. Deen, C.-H. Chen, Microelectron. Reliab. 46, 1939 (2006).

R. K. Nahar, V. Singh and A. Sharma, J. Mater. Sci. Mater. Electron. 18, 615 (2007).

A. Callegari, E. Cartier, M. Gribelyuk, H. F. Okorn-Schmidt and T. Zabel, J. Appl. Phys. 90, 6466 (2001).

F. M. Li et al., Appl. Phys. Lett. 98, 252903 (2011).

V. Dave, P. Dubey, H. O. Gupta and R. Chandra, Thin Solid Films 549, 2 (2013).

B. Chau, S. Datta, M. Doczv, B. Dovle, J. Kavalieros and M. Metz, IEEE Electron Dev. Lett. 25, 408 (2004).

K. L. Ganapathi, N. Bhat and S. Mohan, Semicond. Sci. Technol. 29 055007 (2014).

J. C. Dupin, D. Gonbeau, P Vinatier, A. Levasseur, Phy. Chem. Chem. Phys. 2, 1319 (2000).

L. G. Wang, X. Qian, Y. Q. Cao, Z. Y. Cao, G. Y. Fang, A. D. Li and D. Wu, Nano. Res. Lett. 10, 135 (2015).

G. Aygun, I. Yildiz, J. Appl. Phys. 106, 014312 (2009).

A. Cantas, G. Aygun and R. Turan, Appl. Surf. Sci. 318, 199 (2014)

M. Esro, G. Vourlias, C. Somerton, W. I. Milne and G. Adamopoulos, Adv. Funct. Mater. 25, 134 (2015).

A. Deshpande, R. Inman, G. Jursich and C. Takoudis, Microelectron. Eng. 83, 547 (2006).

S. T. Li, S. J. Slivers and M. S. El-Shall, J. Phys. Chem. B 101, 1794 (1997).

S. Suyama, A. Okamoto and T. Serikawa, Appl. Surf. Sci. 33-4 1236 (1988).

S. Li, X. Qiao and J. Chen, Mater. Chem. Phys. 98, 144 (2006).

Z. Ouennoughi, C. Strenger, F. Bourouba, V. Haeublein, H. Ryssel and L. Frey, Microelectron. Reliab. 53, 1841 (2013).

C. Ko, M. Shandalov, P. C. Mclntyre and S. Ramanathan, Appl. Phys. Lett. 97, 082102 (2010).

S. Zafar, H. Jagannathan, L. F. Edge and D. Gupta, Appl. Phys. Lett. 98, 152903 (2011).

E. A. Weiss, R. C. Chiechi, G. K. Kaufman, J. K. Kriebel, Z. Li, M. Duati, M. A. Rampi and G. M. Whitesides, J. Am. Chem. Soc. 129, 4336 (2007).

G. Blaise, J. Electrostat. 50, 69 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Xu, J., Wang, YN. et al. Facing-target mid-frequency magnetron reactive sputtered hafnium oxide film: Morphology and electrical properties. Journal of the Korean Physical Society 68, 679–685 (2016). https://doi.org/10.3938/jkps.68.679

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.68.679