Abstract

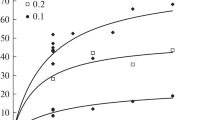

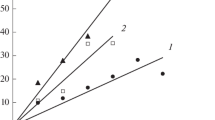

The samples of granulated (2–4 mm) porous carbon material with unimodal and bimodal poresize distributions were prepared. The sample with a unimodal porous structure was prepared via the mixing of soot and petroleum pitch followed by carbonization (the first stage). At the second stage, the carbon material obtained was ground to a particle size smaller than 0.2 mm, mixed with petroleum pitch, and also subjected to carbonization. The porous structures of these materials were studied by scanning electron microscopy and mercury porosimetry. It was established that the predominant pore size (20–1000 nm) of the samples with the unimodal structure depends on the used soot grade. At the second stage of the process, a considerable volume of pores in a range of 4–12 μm is formed in the production of bidisperse material. As compared with a sample with the monodisperse structure, porous carbon material with a bimodal distribution of pores was characterized by a lower crushing strength of granules and comparable specific surface areas, total pore volumes, and ash contents.

Similar content being viewed by others

References

Auer, E., Freund, A., Pietsch, J., and Tacke, T., Appl. Catal., A, 1998, vol. 173, no. 2, p. 259.

Stiles, A.B., Nositeli i nanesennye katalizatory. Teoriya i praktika (Catalyst Supports and Supported Catalysts: Theoretical and Applied Concepts), Slinkin, A.A., Ed. of the Russian translation, Moscow: Khimiya, 1991.

Stiles, A.B., Catalyst Supports and Supported Catalysts: Theoretical and Applied Concepts, Boston: Butterworths, 1987.

Sittig, M., Izvlechenie metallov i neorganicheskikh soedinenii iz otkhodov (Metal and Inorganic Waste Reclaiming Encyclopedia), Emanuel’, N.M., Ed. of the Russian translation, Moscow: Metallurgiya, 1985.

Sittig, M., Metal and Inorganic Waste Reclaiming Encyclopedia, Park Ridge: Noyes Data Corp., 1980.

Marsh, H. and Rodriguez-Reinoso, F., Activated Carbon, London: Elsevier, 2006.

Boreskov, G.K., Geterogennyi kataliz (Heterogeneous Catalysis), Moscow: Nauka, 1986.

Gheorghiu, S. and Coppens, M.-O., React., Kinet., Catal., 2004, vol. 50, no. 4, p. 812.

Kel’tsev, N.V., Osnovy adsorbtsionnoi tekhniki (Basics of Adsorption Instrumentation), Moscow: Khimiya, 1976.

Kim, Y., Kim, C., and Yi, J., Mater. Res. Bull., 2004, vol. 39, no. 13, p. 2103.

Coppens, M.-O., Sun, J., and Maschmeyer, T., Catal. Today, 2001, vol. 69, nos. 1–4, p. 331.

Sun, G., Li, K., Xie, L., et al., Micropor. Mesopor. Mater., 2012, vol. 151, p. 282.

Cai, T., Zhou, M., Han, G., and Guan, S., J. Power Sources, 2013, vol. 241, p. 6.

Lu, A.-H., Schmidt, W., Spliethoff, B., and Schuth, F., Adv. Mater., 2003, vol. 15, no. 19, p. 1602.

Kugatov, P.V. and Zhirnov, B.S., J. Porous Mater., 2013, vol. 20, no. 4, p. 875.

Plachenov, T.G. and Kolosentsev, S.D., Porometriya (Porosimetry), Leningrad: Khimiya, 1988.

Rubinshtein, A.M. and Klyachko-Gurvich, A.L., Kinet. Katal., 1962, vol. 3, no. 4, p. 599.

Rubinshtein, A.M. and Afanas’ev, V.A., Izv. Akad. Nauk SSSR, Otd. Khim. Nauk, 1956, no. 11, p. 1294.

Kiselev, A.V., Iogansen, A.V., Sakodynskii, K.I., et al., Fiziko-khimicheskoe primenenie gazovoi khromatografii (Physicochemical Application of Gas Chromatography), Moscow: Khimiya, 1973.

Brunauer, S., Emmett, P.H., and Teller, E., J. Am. Chem. Soc., 1938, vol. 60, no. 2, p. 309.

Karnaukhov, A.P., Adsorbtsiya. Tekstura dispersnykh i poristykh materialov (Adsorption: Texture of Dispersed and Porous Materials), Novosibirsk: Nauka, Sib. Otd. Ross. Akad. Nauk, 1999.

McClellan, A.L. and Harnsberger, H.F., J. Colloid Interface Sci., 1967, vol. 23, no. 4, p. 577.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © P.V. Kugatov, I.I. Bashirov, B.S. Zhirnov, 2014, published in Khimiya Tverdogo Topliva, 2014, No. 5, pp. 21–25.

About this article

Cite this article

Kugatov, P.V., Bashirov, I.I. & Zhirnov, B.S. Porous carbon material based on petroleum pitch. Solid Fuel Chem. 48, 293–297 (2014). https://doi.org/10.3103/S0361521914050061

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0361521914050061