Abstract

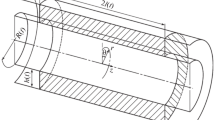

For some models of rigid-plastic bodies, the strain rate fields turn out to be singular near the maximum friction surfaces. In particular, the equivalent strain rate (the second invariant of the strain rate tensor) tends to infinity when approaching such frictions surfaces. The coefficient multiplying the leading singular term in the series expansion of the equivalent strain rate near the maximum friction surfaces is called the strain rate intensity factor. This coefficient occurs in several models predicting the development of intensive plastic deformation layers near friction surfaces and in equations describing the change in the material structure in such layers. In the present paper, the solution is constructed for the compression of a layer of a plastic material obeying the double shear model between cylindrical surfaces on each of which the maximum friction law holds. The dependence of two strain rate intensity factors on the material and process parameters is calculated and analyzed.

Similar content being viewed by others

References

S. Aleksandrov and O. Richmond, “Singular Plastic Flow Fields near Surfaces of Maximum Friction Stress,” Int. J. Non-Lin. Mech. 36(1), 1–11 (2001).

S. E. Aleksandrov and E. A. Lyamina, “Singular Solutions for Plane Plastic Flow of Pressure-Dependent Materials,” Dokl. Ross. Akad. Nauk 383(4), 492–495 (2002). [Dokl. Phys. (Engl. Transl.) 47 (4), 308–311 (2002)].

S. E. Aleksandrov, A. R. Pirumov, and O. V. Chesnikova, “Plastic Flow of Porous Materials in Friction Contact Area,” Poroshk. Metallurg., No. 9–10, 13–20 (2008) [Powder Metall. Met. Ceram. (Engl. Transl.) 1 (9–10), 512–517 (2008)].

S. E. Aleksandrov and E. A. Lyamina, “On the Possibility of Introducing the Strain Rate Intensity Coefficient in Viscoplasticity,” in Actual Problems of Mechanics: Deformable Solid Mechanics, Ed. by R. V. Goldstein (A. Yu. Ishlinskii Institute for Problems in Mechanics, RAS, Nauka, Moscow, 2009) [in Russian], pp. 313–326.

S. E. Aleksandrov and G. Mishuris, “Qualitative Behavior of Viscoplastic Solutions in the Vicinity of Maximum-Friction Surfaces,” J. Engng Math. 65(2), 143–156 (2009).

S. E. Aleksandrov and E. A. Lyamina, “Solving the Problem of Expansion and Extension of a Hollow Cylinder with the Use of the Gradient Plasticity Theory,” Zh. Prikl. Mekh. Tekhn. Fiz. 50(6), 186–192 (2009) [J. Appl. Mech. Tech. Phys. (Engl. Transl.) 50 (6), 1071–1076 (2009)].

A. J. M. Spencer, “A Theory of the Kinematics of Ideal Soils under Plane Strain Conditions,” J. Mech. Phys. Solids 12(5), 337–351 (1964).

V. N. Nikolaevskii, Mechanical Properties of Soils and Plasticity in Mechanics of Deformable Solids, Itogi Nauki i Tekhniki [Progress in Science and Technology], (VINITI, Moscow, 1972), [in Russian].

W. A. Spitzig, R. J. Sober, and O. Richmond, “The Effect of Hydrostatic Pressure on the Deformation Behavior of Maraging and HY-80 Steels and Its Implications for Plasticity Theory,” Metallurg. Trans. 7A(11), 1703–1710 (1976).

V. A. Lomakin, “Nonlinear Deformation of Materials the Strength of which Depend on the Stress-Strain Type,” Izv. Akad. Nauk SSSR. Mekh. Tverd. Tela, No. 4, 92–99 (1980) [Mech. Solids (Engl. Transl.)].

A. S. Kao, H. A. Kuhn, W. A. Spitzig, and O. Richmond, “Influence of Superimposed Hydrostatic Pressure on Bending Fracture and Formability of a Low Carbon Steel Containing Globular Sulfides,” Trans. ASME. J. Engng Mater. Technol. 112(1), 26–30 (1990).

E. Lyamina, S. Aleksandrov, D. Grabko, and O. Shikimaka, “An Approach to Prediction of Evolution of Material Properties in the Vicinity of Frictional Interfaces in metal Forming,” Key Engng Mater. 345–346, 741–744 (2007).

S. E. Aleksandrov and E. A. Lyamina, “Nonlocal Fracture Criterion near Surface Friction and Its Application to Analysis of Drawing and Extrusion,” Probl. Mashinostr. Nadezhn. Mashin, No. 3, 62–68 (2007).

S. E. Aleksandrov, D. Z. Grabko, and O. A. Shikimaka, “To the Determination of Intensive Strain Layer Thickness near the Friction Surface in Metal Forming Processes,” Probl. Mashinostr. Nadezhn. Mashin, No. 3, 72–78 (2009).

S. P. Moylan, S. Kompella, S. Chandrasekar, and T. N. Farris, “A New Approach for Studying Mechanical Properties of Thin Surface Layers Affected by Manufacturing Processes,” Trans. ASME. J. Manuf. Sci. Engng 125, 310–315 (2003).

T. A. Trunina and E. A. Kokovikhin, “Formation of Highly Dispersed Structure in Surface Layers of Steel under Combined Treatment with Hydraulic Forging,” Probl. Mashinostr. Nadezhn. Mashin, No. 2, 71–74 (2008).

S. Alexandrov, “The Strain Rate Intensity Factor and Its Applications: A Review,” Mater. Sci. Forum. 623, 1–20 (2009).

S. Alexandrov and E. Lyamina, “Flow of Pressure-Dependent Plastic Material between Two Rough Conical Walls,” Acta Mech. 187(1–4), 37–53 (2006).

S. E. Aleksandrov and E. A. Lyamina, “Strain Rate Intensity Factors for a Plastic Mass Flow between Two Conical Surfaces,” Izv. Akad. Nauk. Mekh. Tverd. Tela, No. 5, 74–78 (2008). [Mech. Solids (Engl. Transl.) 43 (5), 751–755 (2008)]

S. E. Aleksandrov and E. A. Lyamina, “Strain-Rate Intensity Factor in Compression of a Layer of a Plastic Material between Cylindrical Surfaces,” Zh. Prikl. Mekh. Tekhn. Fiz. 50(3), 171–180 (2009) [J. Appl. Mech. Tech. Phys. (Engl. Transl.) 50 (3), 504–511 (2009)].

L. M. Kachanov, Foundations of the Theory of Plasticity (Gostekhizdat, Moscow, 1956) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.E. Aleksandrov, E.A. Lyamina, 2013, published in Izvestiya Akademii Nauk. Mekhanika Tverdogo Tela, 2013, No. 6, pp. 43–57.

About this article

Cite this article

Aleksandrov, S.E., Lyamina, E.A. Strain rate intensity factors for a plastic material layer compressed between cylindrical surfaces. Mech. Solids 48, 636–648 (2013). https://doi.org/10.3103/S0025654413060071

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654413060071