Abstract

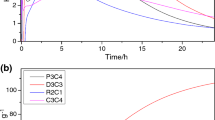

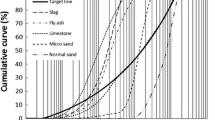

Three fiber-reinforced cement composites were prepared and cured in an autoclave for up to 168 h at 2 MPa of steam pressure in order to investigate the effect of hydrothermal curing on the alteration of pore structure, density, and formation and stability of hydrated products with time. Compressive strength was reviewed in connection with sample porosity. It was found that the time of autoclaving plays a crucial role in objective assessment of the durability of composites as potential candidates for geothermal applications. A mercury intrusion porosimeter Quantachrome Poremaster 60GT was used for the estimation of the pore structure parameters of composites. The thermal analysis method was used to identify different temperature ranges of cured samples’ thermal decomposition and to characterize the nature of hydrated products. Two kinds of products were formed. The first group consisted of calcium-silicate-hydrate (C-S-H), calcium-silicate-aluminate-hydrate (C-S-A-H), calcium-aluminate-hydrate (C-A-H), and calcium-carbonate (C-C) as a product of carbonation. The second group are chemically bond products, e.g. hydroxyapatite (Ca5(PO4)3(OH)) and gibbsite (Al(OH)3). These two hydroceramic products formed under hydrothermal conditions act also as binders and they can be useful as geothermal cement binders.

Similar content being viewed by others

References

Aligizaki, K. K. (2006). Pore structure of cement-based materials: testing, interpretation and requirements. New York, NY, USA: Taylor & Francis.

Ashraf, M., Naeem Khan, A., Qasair, A., Mirza, J., Goyal, A., & Anwar, A. M. (2009). Physico-chemical, morphological and thermal analysis for the combined pozzolanic activities of minerals additives. Construction and Building Materials, 23, 2207–2213. DOI: 10.1016/j.conbuildmat.2008.12.008.

Bägeľ, Ľ., & Palou, M. (2010). Cement composites under hydrothermal load. Effect of prolonged autoclaving on the pore structure alterations. Building Research Journal, 58, 139–156.

Bägeľ, Ľ., & Živica, V. (1997). Relationship between pore structure and permeability of hardened cement mortars: On the choice of effective pore structure parameter. Cement and Concrete Research, 27, 1225–1235. DOI: 10.1016/s0008-8846(97)00111-7.

Berndt, M. L., & Philippacopoulos, A. J. (2002). Incorporation of fibers in geothermal well cements. Geothermics, 31, 643–656. DOI: 10.1016/s0375-6505(02)00028-7.

Collepardi, M., Monosi, S., & Piccioli, P. (1995). The influence of pozzolanic materials on the mechanical stability of aluminous cement. Cement and Concrete Research, 25, 961–968. DOI: 10.1016/0008-8846(95)00091-p.

Day, R. L., & Marsh, B. K. (1988). Measurement of porosity in blended cement pastes. Cement and Concrete Research, 18, 63–73. DOI: 10.1016/0008-8846(88)90122-6.

Drábik, M., Gáliková, Ľ., Balkovic, S., & Slade, R. C. T. (2007). Potential of Portland cements for MDF materials. Journal of Physics and Chemistry of Solids, 68, 1057–1061. DOI: 10.1016/j.jpcs.2007.03.006.

Janotka, I., Krajči, Ľ., Rayb, A., & Mojumdar, S. C. (2003). The hydration phase and pore structure formation in the blends of sulfoaluminate-belite cement with Portland cement. Cement and Concrete Research, 33, 489–497. DOI:10.1016/s0008-8846(02)00994-8.

Jupe, A. C., Wilkinson, A. P., Luke, K., & Funkhouser, G. P. (2008). Class H cement hydration at 180°C and high pressure in the presence of added silica. Cement and Concrete Research, 38, 660–666. DOI: 10.1016/j.cemconres.2007.12.004.

Kalousek, G. L. (1979). Development of cement for geothermal wells. Upton, NY, USA: Brookhaven National Laboratory. (BNL Report 51024 UC 66-D)

Kukacka, L. E., & Sugama, T. (1994). Lightweight CO 2-resistant cements for geothermal well completions. Upton, NY, USA: Brookhaven National Laboratory. (BNL Report60326)

Kula, T. M., Meiser, M. D., & Tressler, R. E. (1980). Curing temperature and humidity effects on the strength of an aluminous cement. Cement and Concrete Research, 10, 491–497. DOI: 10.1016/0008-8846(80)90093-9.

Le Saout, G., Lécolier, E., Rivereau, A., & Zanni, H. (2006). Chemical structure of cement aged at normal and elevated temperatures and pressures: Part I. Class G oilwell cement. Cement and Concrete Research, 36, 71–78. DOI:10.1016/j.cemconres.2004.09.018.

Luke, K., & Taylor, H. F. W. (1984). Equilibria and nonequilibria in the formation of xonotlite and truscottite. Cement and Concrete Research, 14, 657–662. DOI: 10.1016/0008-8846(84)90028-0.

Ma, W., & Brown, P. W. (1992). Mechanical behaviour and microstructural development in phosphate modified high alumina cement. Cement and Concrete Research, 22, 1192–1200. DOI: 10.1016/0008-8846(92)90048-z.

Nelson, E. B., Eilers, L. H., & Kalousek, G. L. (1981). Formation and behavior of calcium silicate hydrates in geothermal environment. Cement and Concrete Research, 11, 371–381. DOI: 10.1016/0008-8846(81)90109-5.

Nilforoushan, M. R., & Talebiaan, N. (2007). The hydration products of a refractory calcium aluminate cement at low temperatures. Iranian Journal of Chemistry & Chemical Engineering-International, 26, 71–76.

Palou, M. T., Živica, V., & Kuliffayová, M. (2010). Thermal and microstructure analysis of fibre reinforced binder composites cured in autoclave. Building Research Journal, 58, 157–173.

Sugama, T. (2006). Advanced cements for geothermal wells. Upton, NY, USA: Brookhaven National Laboratory. (BNL-77901-2007-IR)

Sugama, T., & Carciello, N. R. (1992). Carbonation of hydrothermally treated phosphate-bonded calcium aluminate cements. Cement and Concrete Research, 22, 783–792. DOI:10.1016/0008-8846(92)90102-2.

Sugama, T., Weber, L., & Brothers, L. E. (2000), Sodiumpolyphosphate-modified fly ash/calcium aluminate blend cement: durability in wet harsh geothermal environments. Materials Letters, 44, 45–53. DOI: 10.1016/s0167-577x(00)00002-1.

Taichi, S. (1985). Thermal decomposition of aluminium hydroxides to aluminas, Thermochimica Acta, 88, 69–84. DOI: 10.1016/0040-6031(85)85415-0.

Živica, V. (2009). Effects of the very low water/cement ratio. Construction and Building Materials, 23, 3579–3582. DOI:10.1016/j.conbuildmat.2009.03.014.

Živica, V., & KriŽma, M. (2011). Dependence of efficiency of pressure compaction on the cement type used. Construction and Building Materials, 25, 3073–3077. DOI:10.1016/j.conbuildmat.2010.12.061.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palou, M., Bágeľ, Ľ. Preparation and properties of cementitious composites for geothermal applications. Chem. Pap. 66, 881–890 (2012). https://doi.org/10.2478/s11696-012-0166-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11696-012-0166-y