Abstract

In this study, the effect of CO2 concentration and ambient relative humidity (RH) on accelerated and natural carbonation of 18 concrete mixtures produced with nine different cement types is investigated. Increasing the CO2 concentration from 0.045 to 1 and 4 % at 57 % RH does not alter the relative carbonation resistance between the concrete mixtures. The increase of RH from 57 to 70 and 80 % RH at 4 % CO2 shows a water-to-cement ratio and cement-specific effect that affects the relative carbonation resistance between the concrete mixtures. The carbonation resistance at 4 % CO2 and 57 % RH allows assessing the carbonation resistance of concrete in sheltered and with restrictions in unsheltered outdoor exposure. The carbonation resistance below 70 % RH is mainly governed by the CO2 buffer capacity. However, in the accelerated tests at 80 % RH and in the unsheltered outdoor exposure capillary condensation is of increased importance.

Similar content being viewed by others

References

Wierig HJ (1984) Longtime studies on the carbonation of concrete under normal outdoor exposure. In: Proceedings of the RILEM seminar on the durability of concrete structures under normal outdoor exposure, pp 239–49

Papadakis VG (2000) Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem Concr Res 30:291–299

Rozière E, Loukili A, Cussigh F (2009) A performance based approach for durability of concrete exposed to carbonation. Constr Build Mater 23:190–199

Thomas MDA, Matthews JD (1992) Carbonation of fly ash concrete. Mag Concr Res 44:217–228

De Ceukelaire L, Van Nieuwenburg D (1993) Accelerated carbonation of a blast-furnace cement concrete. Cem Concr Res 23:442–452

Chen CT, Ho CW (2013) Influence of cyclic humidity on carbonation of concrete. J Mater Civ Eng 25:1929–1935

Sanjuàn MA, Andrade C, Cheyrezy M (2003) Concrete carbonation tests in natural and accelerated conditions. Adv Cem Res 15:171–180

Turcry P, Oksri-Nelfia L, Younsi A, Aït-Mokhtar A (2014) Analysis of an accelerated carbonation test with severe preconditioning. Cem Concr Res 57:70–78

Galan I, Andrade C, Castellote M (2013) Natural and accelerated CO2 binding kinetics in cement paste at different relative humidities. Cem Concr Res 49:21–28

Parrot LJ (1991) Factors influencing relative humidity in concrete. Mag Concr Res 43:45–52

Andrade C, Sarría J, Alonso C (1999) Relative humidity in the interior of concrete exposed to natural and artificial weathering. Cem Concr Rese 29:1249–1259

Tuutti K (1982) Corrosion of steel in concrete. Svenska Forskningsinstitutet för cement och betong, Stockholm

González JA, Andrade C (1982) Effect of carbonation, chlorides and relative ambient humidity on the corrosion of galvanized rebars embedded in concrete. Br Corros J 17:21–28

Groves GW, Brough A, Richardson IG, Dobson CM (1991) Progressive changes in the structure of hardened C3S cement pastes due to carbonation. J Am Ceram Soc 74:2891–2896

Goñi S, Gaztañaga MT, Guerrero A (2002) Role of cement type on carbonation attack. J Mater Res 17:1834–1842

Lang E (2003) Einfluss unterschiedlicher Karbonatphasen auf den Frost-Tausalzwiderstand—Labor. und Praxisverhalten. Beton Informationen 5:39–57

Anstice DJ, Page CL, Page MM (2005) The pore solution phase of carbonated cement pastes. Cem Concr Res 35:377–383

Castellote M, Fernandez L, Andrade C, Alonso C (2009) Chemical changes and phase analysis of OPC pastes carbonated at different CO2 concentrations. Mater Struct 42:515–525

Hyvert N, Sellier A, Duprat F, Rougeau P, Francisco P (2010) Dependency of C–S–H carbonation rate on CO2 pressure to explain transition from accelerated tests to natural carbonation. Cem Concr Res 40:1582–1589

Morandeau A, Thiery M, Dangla P (2014) Investigation of the carbonation mechanism of CH and CSH in terms of kinetics, microstructure changes and moisture properties. Cem Concr Res 56:153–170

Morandeau A, Thiéry M, Dangla P (2015) Impact of accelerated carbonation on OPC cement paste blended with fly ash. Cem Concr Res 67:226–236

Auroy M, Poyet S, Le Bescop P, Torrenti JM, Charpentier T, Moskura M, Bourbon X (2015) Impact of carbonation on unsaturated water transport properties of cement-based materials. Cem Concr Res 74:44–58

Leemann A, Nygaard P, Kaufmann J, Loser R (2015) Relation between carbonation resistance, mix design and exposure of mortar and concrete. Cem Concr Compos 62:33–43

Sevelsted TF, Skibsted J (2015) Carbonation of C–S–H and C–A–S–H samples studied by 13C, 27Al and 29Si MAS NMR spectroscopy. Cem Concr Res 71:56–65

Kropp J (1983) Karbonatisierung und Transportvorgänge in Zementstein. Doctoral Thesis, University of Karlsruhe, Germany

Papadakis VG, Vayenas CG, Fardis MN (1991) Physical and chemical characteristics affecting the durability of concrete. Mater J 88:186–196

Papadakis VG, Vayenas CG, Fardis MN (1991) Fundamental modeling and experimental investigation of concrete carbonation. Mater J 88:363–373

Steffens A, Dinkler D, Ahrens H (2002) Modeling carbonation for corrosion risk prediction of concrete structures. Cem Concr Res 32:935–941

Saetta AV, Vitaliani RV (2004) Experimental investigation and numerical modeling of carbonation process in reinforced concrete structures: part I: theoretical formulation. Cem Concr Res 34:571–579

Bary B, Sellier A (2004) Coupled moisture—carbon dioxide–calcium transfer model for carbonation of concrete. Cem Concr Res 34:1859–1872

Diamond S (1971) A critical comparison of mercury porosimetry and capillary condensation pore size distributions of portland cement pastes. Cem Concr Res 1:531–545

Baroghel-Bouny V (2007) Water vapour sorption experiments on hardened cementitious materials part I: essential tool for analysis of hygral behaviour and its relation to pore structure. Cem Concr Res 37:414–437

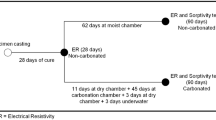

SN 505 262/1 (2013) Betonbau—Ergänzende Festlegungen, Anhang I, Karbonatisierungswiderstand, SIA Zürich

VAB (2015) Ringversuch Karbonatisierungswiderstand, Vereinigung Akkreditierter Baustoffprüflabors. Empa Bericht Nr. 5214007288, Dübendorf

Thiery M, Dangla P, Belin P, Habert G, Roussel N (2013) Carbonation kinetics of a bed of recycled concrete aggregates: a laboratory study on model materials. Cem Concr Res 46:50–65

Lawrence CD (1984) Transport of oxygen through concrete. In: Glasser FP (ed) The chemistry and chemically-related properties of cement. British Ceramic Society proceedings, vol 35, pp 277–293

Buenfeld NR, Okundi E (1998) Effect of cement content on transport in concrete. Mag Concr Res 50:339–351

Villani C, Loser R, West MJ, Di Bella C, Lura P, Weiss JW (2014) An inter lab comparison of gas transport testing procedures: oxygen permeability and oxygen diffusivity. Cem Concr Compos 53:357–366

EN 12390-3 (2002) Testing hardened concrete—part 3: compressive strength of test specimens

Cook RA, Hover KC (1999) Mercury porosimetry of hardened cement pastes. Cem Concr Res 29:933–943

Atahan HN, Oktar ON, Tasdemir MA (2009) Effects of water–cement ratio and curing time on the critical pore width of hardened cement paste. Constr Build Mater 23:1196–1200

Manmohan D, Metha PK (1981) Influence of pozzolanic, slag, and chemical admixtures on pore size distribution and permeability of hardened cement pastes. Cem Concr Aggreg 3:63–67

Frías M, Cabrera J (2000) Pore size distribution and degree of hydration of metakaolin–cement pastes. Cem Concr Res 30:561–569

Aldea CM, Young F, Wang K, Shah SP (2000) Effects of curing conditions on properties of concrete using slag replacement. Cem Concr Res 30:465–472

Chindaprasirt P, Jaturapitakkul C, Sinsiri T (2005) Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem Concr Compos 27:425–428

Powers TC, Brownyard TL (1946) Studies of the physical properties of hardened cement paste. ACI J Proc 43:249–336

Parrott LJ (1992) Variations of water absorption rate and porosity with depth from an exposed concrete surface: effects of exposure conditions and cement type. Cem Concr Res 22:1077–1088

McCarter WJ, Watson DW, Chrisp TM (2001) Surface zone concrete: drying, absorption and moisture distribution. J Mater Civ Eng 13:49–57

Patel RG, Killoh DC, Parrott LJ, Gutteridge WA (1988) Influence of curing at different relative humidities upon compound reactions and porosity in Portland cement paste. Mater Struct 21:192–197

Parrott LJ (1995) Influence of cement type and curing on the drying and air permeability of cover concrete. Mag Concr Res 47:103–111

Houst YF, Wittmann FH (1994) Influence of porosity and water content on the diffusivity of CO2 and O2 through hydrated cement paste. Cem Concr Res 24:1165–1176

Fatthudi NI (1988) Concrete carbonation as influenced by curing regime. Cem Concr Res 18:426–430

Osborne GJ (1989) Carbonation and permeability of blastfurnace slag cement concretes from field structures. ACI Spec Publ 114:1209–1238

Thomas MDA, Matthews JD, Haynes CA (1992) Carbonation of fly ash concrete. ACI Spec Publ 19:539–556

Younsi A, Turcry Ph, Aït-Mokhtar A, Staquet S (2013) Accelerated carbonation of concrete with high content of mineral additions: effect of interactions between hydration and drying. Cem Concr Res 43:25–33

Lothenbach B, Le Saout G, Gallucci E, Scrivener K (2008) Influence of limestone on the hydration of Portland cements. Cem Concr Res 38:848–860

Parrot LJ, Killoh DC (1984) Prediction of cement hydration. Proc Br Ceram Soc 35:41–53

Feng X, Garboczi EJ, Bentz DP, Stutzman PE, Mason TO (2004) Estimation of the degree of hydration of blended cement pastes by a scanning electron microscope point-counting procedure. Cem Concr Res 34:1787–1793

Lumley JS, Gollop RS, Moir GK, Taylor HFW (1996) Degrees of reaction of the slag in some blends with Portland cements. Cem Concr Res 26:139–151

Pane I, Hansen W (2005) Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem Concr Res 35:1155–1164

Kocaba V, Gallucci E, Scrivener KL (2012) Methods for determination of degree of reaction of slag in blended cement pastes. Cem Concr Res 42:511–525

Shi Z, Lothenbach B, Geiker MR, Kaufmann J, Leemann A, Ferreiro S, Skibsted J (2016) Experimental studies and thermodynamic modeling of the carbonation of Portland cement, metakaolin and limestone mortars. Cem Concr Res. doi:10.1016/j.cemconres.2016.06.006

Acknowledgments

The authors would like to thank P. Lura for the careful review of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leemann, A., Moro, F. Carbonation of concrete: the role of CO2 concentration, relative humidity and CO2 buffer capacity. Mater Struct 50, 30 (2017). https://doi.org/10.1617/s11527-016-0917-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-016-0917-2