Abstract

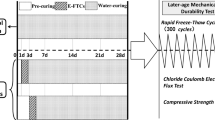

Freeze–thaw exposure of wet-mix sprayed concrete for permanent tunnel linings is characterized by thermal and moisture gradients between wet temperate rock mass/concrete and cold dry concrete/air surface. Hardened sprayed concrete with water/binder ratios in the range of 0.45–0.47 has been studied. The standard freeze/thaw tests like e.g. salt frost scaling according to CEN/TS 12390-9 and rapid freeze/thaw cycling according to ASTM C666 represent much more severe exposure conditions than the worst possible cases in tunnel linings. The sprayed concrete did not pass the salt frost scaling test with 3 % NaCl and rapid freeze/thaw cycling in water but showed no deleterious freezing dilation during sealed freezing following 4–6 months submersion in water. The porosity characteristics, air void content, spacing factor and protective pore factor also indicate a certain freeze–thaw resistance. A new functional performance freezing test method simulating the moisture and freezing gradient exposure conditions in a tunnel lining in a more realistic manner is presented. Reproducible cyclic freeze–thaw exposure during the different test series was measured. Frost damage was measured by resonant frequency on disc shaped specimens prepared from the core sample after gradient frost exposure. The new gradient frost method also indicates frost durability at full capillary saturation on concrete that deteriorated in salt frost scaling- and rapid freeze/thaw tests. The findings of this study suggest that the sprayed concrete in a sprayed concrete lining structure waterproofed with membrane based on ethyl-vinyl-acetate copolymer, is not prone to freeze–thaw damage under the tested moisture and thermal conditions.

Similar content being viewed by others

References

ASTM C215 (2003). Standard test method for fundamental transverse longitudinal and torsional resonant frequencies of concrete specimens

ASTM C457 (2012) Standard test method for microscopical determination of parameters of the air-void system in hardened concrete

ASTM C666 (2008). Standard test method for resistance of concrete to rapid freezing and thawing

ASTM C671-86 (1986). Standard test method for critical dilation of concrete specimens subjected to freezing

Bager DH, Sellevold EJ (1986) Ice formation in hardened cement paste. Part II Drying and resaturation on room temperature cured pastes, Cement and Concrete Research 16(6):835–844

Beaupré D, Talbot C, Gendreau M, Pigeon M, Morgan DR (1994) Deicer salt scaling resistance of dry- and wet process shotcrete. ACI Mater J 91(5):487–494

CEN/TS 12390-9 (2006).Testing hardened concrete, part 9: freeze-thaw resistance scaling

Dilek U (2008) Assessments of damage gradients using dynamic Young’s modulus of thin disks. ACI Mater J 105(5):429–437

Fagerlund G (1977) The critical degree of saturation method of assessing the freeze/thaw resistance of concrete. Mater Struct 10:217–229

Fagerlund G (1995) Freeze-thaw resistance of concrete. Report TVBM-3060, Lund Technical University

Fonseca PC, Scherer GW (2014) An image analysis procedure to quantify the air void system in mortar and concrete. Mater Struct. doi:10.1617/s11527-014-0381-9

Hauck CJ, Kristiansen M (2010) The influence on air content on sprayed concrete quality and sprayability in a civil tunnel. In: Proceedings of the 3rd international conference on engineering developments in Shotcrete, Queenstown, New Zealand, Taylor and Francis, London

Highway Research Board (1959) Special Report 47, Report on cooperative freezing and thawing tests of concrete, Washington D.C

Holter KG (2014) Loads on sprayed waterproof tunnel linings in jointed hard rock – a study based on Norwegian cases. Rock Mech Rock Eng 47:1003–1020

Holter KG, Foord R (2015) Testing of properties and constructability considerations of EVA-based sprayed membranes for waterproofing of tunnels. In: Proceedings of the ITA/AITES 2015 world tunnel congress, Hubitg, Zagreb

Holter KG, Geving S (2015) Moisture transport through sprayed concrete tunnel linings. Rock Mech Rock Eng. doi:10.1007/s00603-015-0730-1

Jacobsen S, Farstad T, Gran HC, Sellevold EJ (1993) Frost/salt scaling of no-slump concrete. Effects of strength, air-entraining agent and condensed silica fume. Nordic Concr Res Publ 12(1):57–71

Jacobsen S, Sellevold EJ, Matala S (1996) Frost durability of high strength concrete: effect of internal cracking on ice formation. Cem Concr Res 26(6):919–931

Jacobsen S (1997) Scaling and cracking in wet freeze/thaw testing. In: M.J. Setzer, R. Auberg (ed) RILEM proc. 34, frost resistance of concrete, pp 246–254

Jacobsen S, Melandsø F, Nguyen HT (2004) Flow calculation and thermodynamics in wet frost exposure of cement based materials. In: Proceedings of the international RILEM symposium on the advances in concrete through science and engineering, Evanston

Jolin M, Baupré D, Pigeon M, Lamontage A (1997) Use of set accelerating admixtures in dry-mix shotcrete. J Mater Civ Eng 9:180–184

Leming ML, Na J, Fukuda J (1998) Nondestructive determination of the dynamic Young’s modulus of concrete disks. ACI Mater J 95(1):50–57

Malhotra VM (1982) Mechanical properties and freezing and thawing resistance of non-air entrained, air-entrained and air-entrained superplasticized concrete using ASTM C666 procedures A and B. Cem Concr Aggreg (ASTM) 4(1):3–23

Myren S, Bjøntegaard Ø (2014). Fiber reinforced sprayed concrete: Mechanical properties and pore structure characteristics. In: Proceedings of the 7th international symposium on sprayed concrete, Sandefjord, Norway, Tekna/Norwegian Concrete Association, Oslo

NBG Norwegian Rock Mechanics Group (2000) Handbook No 2 Engineering Geology and Rock Engineering. Norwegian Tunneling Society, Oslo

NCA Norwegian Concrete Association (2011) Publication No 7 Sprayed Concrete Handbook, Tekna. Oslo

NPRA Norwegian Public Roads Administration (2007) Handbook 014, laboratory investigations (in Norwegian). Norwegian Public Roads Administration, Oslo

NPRA Norwegian Public Roads Administration, (2012). Major Research and Development Project: Modern Road Tunnels 2008–2011(Norwegian). Report No. 127. Norwegian Public Roads Administration, Oslo

NTNU (2013) Tunnel. Isotropic thermal conductivity and specific heat capacity of various rock and concrete samples determined with the transcient plane source technique. Report 13.October 2013. NTNU Department of Energy and Process Engineering, Trondheim

Powers TC & Brownyard TL (1948). Studies of the Physical Properties of Hardened Cement Paste. Bulletin no 22, Portland Cement Association, Skokie

Powers TC (1949) In: Proceedings of the Highway Research Board, vol 29, pp 184–202

Schrader E, Kaden R (1987) Durability of shotcrete. ACI 2:1071–1101

Sellevold EJ (1988) Concrete technology basic course compendium. NTNU, Trondheim

Sellevold EJ & Farstad T (2005) The PF-method—a simple method to estimate the w/c ratio and air content of hardened concrete, In: Proceedings of the S Mindess symposium, ConMat conference, Vancouver 2005

SFS 4475 (1988) Concrete. Frost resistance. Protective pore ratio. Finnish Standards Association SFS, Helsinki

SIA Schweizer Ingenieur- und Architektenverein (2003), Norm 197/1 Design of Tunnels. Rail tunnels. SIA, Zürich

SINTEF (1988) Capillary absorption as a quality criterion. Report No STF25, A88028 (in Norwegian). SINTEF, Trondheim

Swedish Transport Administration (Trafikverket) (2012) Temperature flow in rail tunnels—the Glödberg tunnel. Status report 2010. Publication no 2012.095. Trafikverket, Borlänge (Swedish)

Swedish Transport Administration (Trafikverket) (2014) Design of underground structures in rock. Report no 2014.144. Trafikverket, Borlänge (Swedish)

Valenza J, Scherer GW (2006) Mechanism for salt scaling. J Am Ceram Soc 89(4):1161–1179

Acknowledgments

Mrs Maren Kristine Tandberg is acknowledged for having conducted a substantial part of the testing according to ASTM C666 procedure A and participating in developing the tunnel lining freezing test method. Mrs Bente McGonnell at the laboratory of the Norwegian Public Roads Administration is acknowledged for having conducted the salt scaling testing according to CEN-TS 12390-9. The Norwegian Public Roads Administration and the Norwegian National Rail Administration’s site organizations at the E6-highway & Dovre rail line joint project, the E39 Harangen highway tunnel project and the Gevingås rail tunnel are acknowledged for having made locations available for the construction, monitoring and sample preparation for this study. Finally the Norwegian National Rail Administration, the Norwegian Public Roads Administration, BASF Construction Chemicals Europe AG, Orica International Ltd are acknowledged for financial support for this research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Holter, K.G., Smeplass, S. & Jacobsen, S. Freeze–thaw resistance of sprayed concrete in tunnel linings. Mater Struct 49, 3075–3093 (2016). https://doi.org/10.1617/s11527-015-0705-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0705-4