Abstract

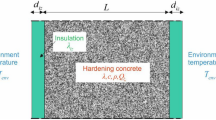

As the demand for energy growing rapidly these years, liquefied natural gas (LNG) has become one of the significant parts of the energy source for its high calorific value and performances, as well as the ease of transport and storage. Hence, increasing number of LNG tank has been constructed. The outer wall of LNG tank is usually made by reinforced concrete and the thermal induced cracking may occur during construction period because of the heat of hydration and concrete shrinkage. The finite element (FE) method was adopted in this paper to study the temperature and thermal stress distribution on the concrete wall of a 160,000 m3 LNG tank. The detailed FE model was first established and mesh convergence analysis was conducted to determine the suitable element size. The heat transfer analysis was conducted to obtain the temperature field on the concrete wall, based on which the incremental method was adopted to calculate the thermal stress. The thermal induced cracks distribution was then obtained by comparing the first principle tensile stress with the ultimate tensile stress of concrete. It was found that the cracks in vertical direction appeared at the concrete wall surface and the cracks in circumferential direction appeared at the buttress column surface. In addition, the major influence factors on the thermal stress were also investigated and the construction season and quality showed significantly effect on the thermal stress.

Similar content being viewed by others

References

BS 7777, Flat-bottomed, vertical, cylindrical storage tanks for low temperature service, BS 7777, 1993

BS EN 14620-1. Design and manufacture of site built, vertical, cylindrical, flat-bottomed steel tanks for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and −165 °C—Part 1: General, BS EN 14620-1, 2006

ACI Committee 301, Specifications for structural concrete, ACI 301M-10, 2010

NFPA-59A, Standard for the production, storage, and handling of liquefied natural gas (LNG), NFPA-59A, 2009

Dahmani L (2011) Thermomechanical response of LNG concrete tank to cryogenic temperatures. Strength Mater 43(5):526–531

Zareian F, Sampere C, Sandoval V, McCormick DL, Moehle J, Leon R (2012) Reconnaissance of the Chilean wine industry affected by the 2010 Chile offshore Maule earthquake. Earthq Spectra 28(1):S503–S512

Brunesi E, Nascimbene R, Pagani M, Beilic D (2014) Seismic performance of storage steel tanks during the May 2012 Emilia, Italy, earthquakes. J Perform Constr Facil. doi:10.1061/(ASCE)CF.1943-5509.0000628

Jeon SJ, Jin BM, Kim YJ et al (2007) Consistent thermal analysis procedure of LNG storage tank. Struct Eng Mech 25(4):445–466

Huang CX (1999) The three dimensional modelling of thermal cracks in concrete structure. Mater Struct 32:673–678

Santurjian O, Kolarow L (1996) A spatial FEM model of thermal stress state of concrete blocks with creep consideration. Comput Struct 58(3):563–574

Lawrence AM, Tia M, Ferraro CC, Bergin M (2012) Effect of early age strength on cracking in mass concrete containing different supplementary cementitious materials: experimental and Finite-Element investigation. J Mater Civ Eng 24:362–372

Larsson O, Thelandersson S (2011) Estimating extreme values of thermal gradients in concrete structures. Mater Struct 44:1491–1500

Wu S, Huang D, Lin FB, Zhao H, Wang P (2011) Estimation of cracking risk of concrete at early age based on thermal stress analysis. J Therm Anal Calorim 105:171–186

Borst R, Boogaard AH (1994) Finite-element modeling of deformation and cracking in early-age concrete. J Eng Mech 120:2519–2534

Buffo-Lacarriere L, Sellier A, Turatsinze A, Escadeillas G (2011) Finite element modelling of hardening concrete: application to the prediction of early age cracking for massive reinforced structures. Mater Struct 44:1821–1835

Zhou Y, Meng D, Wang Y (2014) Finite-element simulation of hydration and creep of early-age concrete materials. J Mater Civ Eng 26(11):05014006

Schutter GD (2002) Finite element simulation of thermal cracking in massive hardening concrete elements using degree of hydration based material laws. Comput Struct 80:2035–2042

Klemczak BA (2014) Modeling thermal-shrinkage stresses in early age massive concrete structures—comparative study of basic models. Arch Civ Mech Eng 14:721–733

Wu Y, Luna R (2001) Numerical implementation of temperature and creep in mass concrete. Finite Elem Anal Des 37:97–106

Machida N, Uehara K (1987) Nonlinear thermal stress analysis of a massive concrete structure. Comput Struct 26(1/2):287–296

Saetta A, Roberto S, Vitaliani R (1995) Stress analysis of concrete structures subjected to variable thermal loads. J Struct Eng 121:446–457

Chen HLR, Choi JH (2011) Analysis of shrinkage and thermal stresses in concrete slabs reinforced with GFRP rebars. J Mater Civ Eng 23:612–627

Zaidi A, Masmoudi R, Bouhicha M (2013) Numerical analysis of thermal stress-deformation in concrete surrounding FRP bars in hot region. Constr Build Mater 38:204–213

Utsi S, Jonasson JE (2012) Estimation of the risk for early thermal cracking for SCC containing fly ash. Mater Struct 45:153–169

Yoshitake I, Wong H, Ishida T, Nassif AY (2014) Thermal stress of high volume fly-ash (HVFA) concrete made with limestone aggregate. Constr Build Mater 71:216–225

Yan YL, Yao DX (2005) Construction of guangdong LNG receiving station with technique of DOKA from. Qual Civ Eng Constr 5:27–29 (In Chinese)

The National Standard of the People’s Republic of China (2010) Code for design of concrete structures (GB 50010-2010). China Architecture & Building Press, Beijing. (In Chinese)

Wang XG, Gao HS, Wen BL (2009) Key technologies for calculation of the mass concrete temperature field with ANSYS. China Harb Eng 1:41–44 (In Chinese)

Huang X, Pang PP, Liu Y (2010) The simulated analysis of temperature stress produced by hydration heat generated in the concrete structure. J Anhui Inst Archit Ind (Nat Sci) 18(3):16–23 (In Chinese)

Liu F (2009) Finite element analysis of temperature field and thermal stress field of mass concrete foundation of tall building. Master Thesis, Tianjin University (In Chinese)

Zhang ST, Li M (2006) Application of ANSYS in the analysis of temperature field and thermal stress of concrete structure. China Water Transp (Theory Ed) 4(5):54–56 (In Chinese)

Chen CH (2006) Analysis of temperature field and thermal stress in construction considering the influence of reinforcement. Master Thesis, Hohai University. (In Chinese)

Guan ZW (2008) The addition method based on ANSYS to analyse the elastic creep thermal stress of big size concrete building. Water Sci Eng Technol Suppl:83–85 (In Chinese)

Sun W (2005) Finite element analysis of temperature field & thermal stress of massive concrete. Constr Des Proj 10:25–27 (In Chinese)

Wu SX, Zhou D (1993) Optimal determination of stress relation coefficients of thermal stress in massive concrete. J Hohai Univ 21(2):47–53 (In Chinese)

Zhu BF (1999) Thermal stress of mass concrete and temperature control. China Electric Power Press, Beijing (In Chinese)

Wang TM (1997) Crack control in engineering structure. China Architecture & Building Press, Beijing (In Chinese)

Harbin Institute of Technology, Dalian University of Technology, Beijing Institute of Civil Engineering and Architecture (2002) Concrete and masonry structure. China Architecture & Building Press, Beijing (In Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhai, X., Wang, Y. & Wang, H. Thermal stress analysis of concrete wall of LNG tank during construction period. Mater Struct 49, 2393–2406 (2016). https://doi.org/10.1617/s11527-015-0656-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0656-9