Abstract

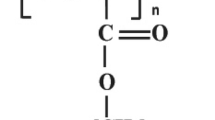

Smoothing of the nanometer-scale asperities of a poly(methyl methacrylate) (PMMA) film using vacuum ultraviolet (VUV) with the wavelength λ = 123.6 nm was studied. The exposure time and the residual air pressure in an working chamber were varied during the process of VUV treatment. A nanostructured surface of PMMA film is used as a sample to be exposed. The nanostructured surface of the PMMA film was obtained by treating the initially smooth spin-coated film in oxygen radio-frequency plasma. The degree of VUV exposure is estimated using changes in the morphology and roughness of the nanostructured surface, which were determined by atomic-force microscopy (AFM). Recognition of morphological surface features on the AFM-images and determination of main geometrical characteristics of these features are performed by using virtual feature-oriented scanning method. It is discovered by morphology and Fourier spectra that the nanostructured surface of the PMMA film is partially ordered. The developed VUV smoothing procedure can be used to treat the electron-beam, UV, and X-ray sensitive PMMA resists, PMMA elements of microelectromechanical systems, biomedical PMMA implants, as well as to certify nanotechnological equipment incorporating UV radiation sources.

Similar content being viewed by others

Reference

H. H. Solak, J. Phys. D. 39, R171 (2006).

E. Dubois and J.-L. Bubbendorff, Solid-State Electron. 43, 1085 (1999).

J. Hartwich, L. Dreeskornfeld, V. Heisig, et al., Appl. Phys. A 66, S685 (1998).

L. J. Guo, J. Phys. D. 37, R123 (2004).

F. Zhang and H. Y. Low, Nanotecnology 17, 1884 (2006).

K.-S. Kim, Y. Ando, and K.-W. Kim, Nanotecnology 19, 105701 (2008).

Y. Guo, G. Liu, Y. Xiong, and Y. Tian, J. Micromech. Microeng. 17, 9 (2007).

J. M. Li, C. Liu, X. D. Dai, et al., J. Micromech. Microeng. 18, 095021 (2008).

M. Haiducu, M. Rahbar, I. G. Foulds, et al., J. Micro-mech. Microeng. 18, 115029 (2008).

S. E. Pel’tek, T. N. Goryachkovskaya, V. M. Popik, et al., Ross. Nanotekhnol. 3(9–10), 136 (2008).

S. W. Li, J. H. Xu, Y. J. Wang, et al., J. Micromech. Microeng. 19, 015035 (2009).

M. E. Vlachopoulou, A. Tserepi, P. Pavli, et al., J. Micromech. Microeng. 19, 015007 (2009).

A. Nisar, N. Afzulpurkar, B. Mahaisavariya, and A. Tuantranont, Sens. Transducers 94, 176 (2008).

N. Gomathi, A. Sureshkumar, and S. Neogi, Current Sci. 94, 1478 (2008).

K. A. Valiev, L. V. Velikov, Yu. I. Dorofeev, et al., Poverkh-nost: Fiz. Khim. Mekh., No. 6, 86 (1985).

C. Peth, F. Barkusky, and K. Mann, J. Phys. D. 41, 105202 (2008).

J. Chai, F. Lu, B. Li, and D. Y. Kwok, Langmuir 20, 10919 (2004).

H. Lim, Y. Lee, S. Han, et al., J. Vac. Sci. Technol. A 19, 1490 (2001).

N. Vourdas, A. Tserepi, and E. Gogolides, Nanotecnology 18, 125304 (2007).

S. Yoshida, T. Ono, and M. Esashi, Nanotecnology 19, 475302 (2008).

D. K. Singh, R. V. Krotkov, H. Xiang, et al., Nanotecnology 19, 245305 (2008).

J. H. Choi, S. M. Adams, and R. Ragan, Nanotecnology 20, 065301 (2009).

S. Magonov and Y. Godovsky, Am. Lab. 31, 52 (1999).

J. F. Jorgensen, K. Carneiro, and L. L. Madsen, Nanotecnology 4, 152 (1993).

Ya. A. Rudzit and V. N. Plutalov, in Principles of Metrology, Precision and Reliability in Instrument Design (Mashi-nostroenie, Moscow, 1991) [in Russian].

R. V. Lapshin, Nanotecnology 15, 1135 (2004); www.niifp.ru/staff/lapshin/en.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © R.V. Lapshin, A.P. Alekhin, A.G. Kirilenko, S.L. Odintsov, V.A. Krotkov, 2010, published in Poverkhnost’. Rentgenovskie, Sinkhrotronnye i Neitronnye Issledovaniya, No. 1, pp. 5–16.

Rights and permissions

About this article

Cite this article

Lapshin, R.V., Alekhin, A.P., Kirilenko, A.G. et al. Vacuum ultraviolet smoothing of nanometer-scale asperities of Poly(methyl methacrylate) surface. J. Surf. Investig. 4, 1–11 (2010). https://doi.org/10.1134/S1027451010010015

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451010010015