Abstract

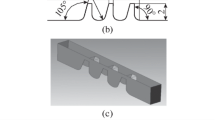

The efficiency, vibration stability, operational durability, and cost of the main types of peripheral seals used in steam turbines are considered. A comparison between the conventional and honeycomb seals is given. Conditions subject to which replacement of conventional seals by honeycomb ones can be justified are pointed out. The use of variable-pitch multicomb seals as the most promising ones is recommended.

Similar content being viewed by others

References

A. G. Kostyuk, Dynamics and Strength of Turbine Machines (MEI, Moscow, 2007) [in Russian].

A. G. Kostyuk, V. V. Frolov, A. E. Bulkin, and A. D. Trukhnii, Steam and Gas Turbines for Power Stations (MEI, Moscow, 2008) [in Russian].

S. V. Ushinin, “Experience gained from using honeycomb seals in steam turbines,” Elektr. Stn., No. 10, 8–14 (2009).

A. G. Kostyuk and B. N. Petrunin, “Comparison between the flow rate and dynamic characteristics of radial and radial-axial seals used in turbine machines,” Vestnik MEI, No. 1, 45–47 (1999).

E. V. Ur’ev and S. V. Zhukov, “About the use of honeycomb seals in steam turbines,” Elektr. Stn., No. 9, 40–44 (2008).

S. V. Zhukov, A. V. Kistoichev, K. V. Shaposhnikov, and E. V. Ur’ev, “Analyzing the use of honeycomb seals in steam turbine designs,” Elektr. Stn., No. 2, 27–31 (2013).

A. G. Kostyuk, A. P. Ruchnov, and A. I. Kumenko, “Calculating the Parameters Characterizing the Dynamic Stability of the Shaft Systems Used in Large-Capacity Steam Turbine Sets,” Therm. Eng. 37(8) (1987).

A. G. Kostyuk and D. P. Pokhodenko, “Improving a turbine unit of the 160-MW class,” Vestnik MEI, No. 5, 64–71 (2001).

A. G. Kostyuk, V. G. Gribin, and A. D. Trukhnii, “The concept of a new-generation steam turbines for coal power engineering in Russia. Part 1. Economic and technical substantiation of the concept,” Therm. Eng. 57(12), 1018 (2010).

V. L. Shvetsov, I. I. Kozheshkurt, V. A. Konev, and A. V. Konoplya, “Main trends of development of steam-turbine construction in OAO Turboatom,” Therm. Eng. 59(2), 100 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.G. Kostyuk, 2015, published in Teploenergetika.

Rights and permissions

About this article

Cite this article

Kostyuk, A.G. Selection of labyrinth seals in steam turbines. Therm. Eng. 62, 14–18 (2015). https://doi.org/10.1134/S0040601515010061

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601515010061