Abstract

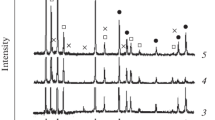

The structure and tribological behavior of composite materials (CMs) filed by dispersed particles and based on aluminum alloys grown by reactive casting with titanium microparticles and SiC nanoparticles or synthetic diamond mixed to the melt have been studied. The composition, size, and volume fraction of the strengthening phases are determined by optical microscopy and x-ray diffraction. The hardness of the CMs is measured. The tribological properties of the CMs are tested during dry friction on a rider made of grade 45 steel. Alloying nanoparticles are shown to affect the morphology, volume fraction, and sizes of the strengthening phases formed in the CMs. The main phases in the CMs are intermetallic compounds Al3Ti, Al24Ti9, and AlTi. The introduction of SiC nanoparticles in a CM causes the formation of TiSi2 (<1%) particles, whereas TiC carbides (<1%) form in a CM containing diamond nanoparticles. CM-steel friction interaction causes the formation of intermediate layers consisting of mechanical mixtures with an ultrafine-grained structure between the sliding surfaces. Their effect on the stable-friction range is discussed.

Similar content being viewed by others

References

A. V. Panfilov, A. A. Panfilov, T. A. Chernyshova, et al., “New Aluminium-Matrix Composite Materials Fabricated in situ,” in Proceedings of the International Conference on the Theory and Practice of the Production of Articles Made of Composite Materials and New Metallic Alloys (TPKMM), Moscow, Russia (Znanie, Moscow, 2004), pp. 136–140.

A. V. Petrunin, A. V. Panfilov, and A. A. Panfilov, “Formation of the Microstructure of Aluminium-Matrix Composite Materials Alloyed by Filling Nanomaterials,” in Proceedings of the 26th International Conference on Composite Materials in Industry, Yalta, Ukraine (UNTs, Nauka. Tekhnika. Tekhnologiya, 2006), pp. 347–348.

C. Cui and R. Wu, “Fabrication of in-situ Reacted AIN-TiC/Al Composite,” in Proceedings of the 10th International Conference on Composite Materials (ICCM-10), Vol. II: Metal Matrix Composites, 1995, pp. II-153–II-159.

I. G. Fruks and I. A. Buinovskii, Introduction to Tribology (Neft’i Gaz, Moscow, 1995) [in Russian].

D. N. Garkunov, Tribological Engineering (Moscow, Mashinostroenie, 1989) [in Russian].

K. L. Tee, Lu, and M. O. Lai, “Wear Performance of insitu Al-TiB2 Composite,” Wear 240, 59–64 (2000).

N. Saheb, T. Laoui, A. R. Daud, et. al., “Influence of Ti Addition on Wear Properties of Al-Si Eutectic Alloys,” Wear 249, 656–662 (2001).

T. A. Chernyshova, L. I. Kobeleva, and L. K. Bolotova, “Tribological Properties of Precipitation-Hardening Aluminum-Matrix Composites under Dry Friction conditions,” in Proceedings of the 4th International Conference MEE-2006, Yalta, Russia (Akademperiodika, Yalta, 2006), p. 20.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © T.A. Chernyshova, L.K. Bolotova, I.E. Kalashnikov, L.I. Kobeleva, P.A. Bykov, 2007, published in Metally, 2007, No. 3, pp. 79–84.

Rights and permissions

About this article

Cite this article

Chernyshova, T.A., Bolotova, L.K., Kalashnikov, I.E. et al. Effect of refractory nanoparticles on the structural modification of metal-matrix composites. Russ. Metall. 2007, 236–241 (2007). https://doi.org/10.1134/S0036029507030123

Received:

Issue Date:

DOI: https://doi.org/10.1134/S0036029507030123