Abstract

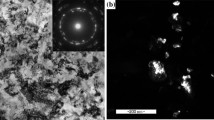

Studies of the deformation and evolution of temperature fields in flat specimens of BT1-0 titanium in the Coarse-Grained (CG) and nanostructured/ultrafine-grained (NS/UFG) states and BT6 titanium alloy were performed. The yield and ultimate stresses for NS/UFG BT1-0 titanium are twice as high as those for the CG state and are comparable with the characteristics of the BT6 alloy. It was found that the ultimate strain before damage of NS/UFG titanium specimens that are tensioned at a constant deformation rate of 6.5 × 10−3 s−1 decreases by a factor of 2. In the region of a macroscopic localization of a plastic deformation the temperature abruptly rises and reaches the maximum values in the crack formation zone. An abrupt temperature increase in the zones of localization of plastic deformations and crack formation is observed in specimens with both the CG and NS/UFG states. Comparing the experimental data on the temperature distributions on the surfaces of strained CG and NS/UFG titanium specimens shows that a macroscopic plastic deformation develops more uniformly in BT1-0 titanium in the NS/UFG state. Under identical loading conditions, the heat release rate is higher for BT1-0 titanium in the NS/UFG state.

Similar content being viewed by others

References

Sharkeev, Yu.P., Belyavskaya, O.A., Polenichkin, V.K., Klimentenko, O.P., Fortuna, S.V., and Polenichkin, S.V., RF Patent no. 2376955, 2009.

Sharkeev, Yu.P., Belyavskaya, O.A., Polenichkin, V.K., Khlusov, I.A., Fortuna, S.V., and Lukonin, S.E., RF Patent no. 71537, 2008.

Sharkeev, Yu.P., Eroshenko, A.Yu., Bratchikov, A.D., Legostaeva, E.V., and Kukarenko, V.A., Structure and Mechanical Properties of Nanostuctured Titanium after Prerecrystallization Annealings, Fizich. Mezomekhan., 2005, vol. 8.

Sharkeev, Yu.P., Eroshenko, A.Yu., Bratchikov, A.D., Legostaeva, E.V., Danilov, V.I., and Kukareko, V.A., Bulk Ultrafine-Grained Titanium with High Mechanical Properties for Medical Implants, Nanotekhnika, 2007, no. 3(11), pp. 81–88.

Eroshenko, A.Yu., Sharkeev, Yu.P., Tolmachev, A.I., Korobitsyn, G.P., and Danilov, V.I., Structure and Properties of Bulk Ultrafine-Grained Titanium Obtained by abc-Pressing and Rolling, Perspekt. Mater., 2009, special issue, no. 7, pp. 107–112.

Sharkeev, Yu.P., Polenichkin, V.K., and Belyavskaya, O.A., Prospects of Application of Ultrafine-Grained Titanium in Dental Implantology, Materialy Mezhdunarodnoi Nauchno-Prakticheskoi Konferentsii “Sostoyanie I Perspektivy Transplantologii” (Proc. of Int. Scientific and Practical Conf. “State and Prospects of Transplantology,” 2008); Minsk: Belorusskaya nauka, 2008, pp. 116–118.

Plekhov, O.A., Uvarov, S.V., Sant’e, N., Palen-Luk, T., and Naimark, O.B., Studying Fatigue Straining of Materials Using the IR Thermography Method, Deform. Razrush. Mater., 2005, no. 11, pp. 39–43.

Vavilov, V.P., Infrakrasnaya termografiya i teplovoi kontrol’ (Infrared Thermography and Thermal Testing), Moscow: Spektr, 2009.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.P. Sharkeev, V.P. Vavilov, V.A. Skripnyak, V.A. Klimenov, O.A. Belyavskaya, D.A. Nesteruk, A.A. Kozulin, A.I. Tolmachev, 2011, published in Defektoskopiya, 2011, Vol. 47, No. 10, pp. 68–75.

Rights and permissions

About this article

Cite this article

Sharkeev, Y.P., Vavilov, V.P., Skripnyak, V.A. et al. Evolution of the temperature field during deformation and fracture of specimens of coarse-grained and ultrafine-grained titanium. Russ J Nondestruct Test 47, 701–706 (2011). https://doi.org/10.1134/S1061830911100147

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830911100147