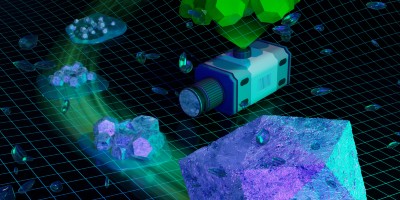

3D printing can be used to automate the manufacturing of building elements for large-scale structures such as skyscrapers, aircraft, rockets and space bases without human intervention. However, challenges in materials, processes, printers and software control must first be overcome for large-scale 3D printing to be adopted for widespread applications.

References

Gu, D. et al. Material-structure-performance integrated laser-metal additive manufacturing. Science 372, eabg1487 (2021).

Ngo, T. D. et al. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. B Eng. 143, 172–196 (2018).

Zuo, Z. et al. Experimental research on transition from scale 3D printing to full-size printing in construction. Constr. Build. Mater. 208, 350–360 (2019).

Chen, S. & Zuo, Z. Shanghai Construction Group builds China’s first on-site 3D printed habitable and deliverable two-story building, which is a national key R&D program demonstration project. Shanghai Construction Group https://mp.weixin.qq.com/s/7jGrrEZMYm0dD0k3iuoCRA (2022).

Schaedler, T. A. & Carter, W. B. Architected cellular materials. Annu. Rev. Mater. Res. 46, 187–210 (2016).

Zhang, K. et al. Aerial additive manufacturing with multiple autonomous robots. Nature 609, 709–717 (2022).

De Schutter, G. et al. Vision of 3D printing with concrete — technical, economic and environmental potentials. Cem. Concr. Res. 112, 25–36 (2018).

Cesaretti, G. et al. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 93, 430–450 (2014).

Bechthold, M. & Weaver, J. C. Materials science and architecture. Nat. Rev. Mater. 2, 17082 (2017).

Vantyghem, G., De Corte, W., Shakour, E. & Amir, O. 3D printing of a post-tensioned concrete girder designed by topology optimization. Automat. Constr. 112, 103084 (2020).

Acknowledgements

This work is supported by the National Key R&D Program of China (no. 2018YFC0705800), the Science and Technology Commission of Shanghai Municipality (no. 19QB1403300) and Shanghai Construction Group R&D Program (no. 14GLXX-05 and 16JCYJ-02). The authors acknowledge J. Gong of SCG for his help in implementing research and engineering projects of LS3DP over the years. The authors thank M. Gong and C. Lu of SCG and C. Gao of KENYO for their help in preparing the figure.

Author information

Authors and Affiliations

Contributions

Z.Z., Y.H., X.C., J.L. and Longlong Zhang researched data for the article. Z.Z., W.D.C. and V.M. contributed substantially to discussion of the content. All authors wrote the article. Z.Z., W.D.C., Y.Z., J.X., Y.Y., K.Z., Lulu Zhang and V.M. reviewed and edited the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Zuo, Z., De Corte, W., Huang, Y. et al. Propelling the widespread adoption of large-scale 3D printing. Nat Rev Mater (2023). https://doi.org/10.1038/s41578-023-00626-1

Published:

DOI: https://doi.org/10.1038/s41578-023-00626-1

- Springer Nature Limited