Abstract

Targets are essential in experimental nuclear sciences as a source of stationary nuclei for nuclear reactions with ion beams. Typically, targets should be chemically pure, uniform, homogeneous and crack-free over the irradiation area, while also being structurally rigid. The polymer-assisted deposition (PAD) method uses a water-soluble multidentate polymer that chelates metal precursors in solution. This polymer-metal solution is then spin coated and annealed to yield a crack-free, homogeneous metal oxide film. In this protocol, nuclear targets are created using PAD on silicon nitride (Si3N4) windows with silicon frames. Silicon wafers ([100], single-side polished) coated with 1 μm of silicon nitride on both sides are patterned and etched to create 1-μm silicon nitride windows. The PAD solution is then spun onto the silicon nitride window and annealed to create a thin, uniform metal oxide film of variable thickness on top of the silicon nitride backing. The production of a target window and the deposition of a thin film ranging from 50 to 150 nm takes ∼13.5 h. Subsequent reapplications to grow thicker films require an additional 5 h per application.

Similar content being viewed by others

References

Greene, J.P., Heinz, A., Falout, J. & Janssens, R.V.F. Rotating target wheel system for super-heavy element production at ATLAS. Nucl. Instrum. Methods Phys. Res. A 521, 214–221 (2004).

Clifford, S., Guo-ji, X., Ingelbrecht, C. & Pomeroy, M.J. Processes for the production of ultra-pure metals from oxide and their cold rolling to ultra-thin foils for use as targets and as reference materials. Nucl. Instrum. Methods Phys. Res. A 480, 29–35 (2002).

Grossmann, R., Maier, H.J., Friebel, H.U. & Frischke, D. Preparation of radioactive targets for tandem accelerator experiments by high vacuum evaporation–condensation. Nucl. Instrum. Methods Phys. Res. A 480, 209–213 (2002).

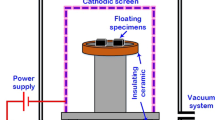

Eberhardt, K., Schädel, M., Schimpf, E., Thörle, P. & Trautmann, N. Preparation of targets by electrodeposition for heavy element studies. Nucl. Instrum. Methods Phys. Res. A 521, 208–213 (2004).

Drapchinsky, L.V., Kuzmina, T.E. & Soloviev, S.M. Practice of using the multiple painting method. Nucl. Instrum. Methods Phys. Res. A 438, 116–118 (1999).

Chakrabarty, S., Tomar, B.S., Goswami, A., Raman, V.A. & Manohar, S.B. Preparation of thin osmium targets by electrodeposition. Nucl. Instrum. Methods Phys. Res. B 174, 212–214 (2001).

Glover, K.M., Rogers, F.J.G. & Tuplin, T.A. Techniques used at Harwell in the preparation of stable and active nuclide targets. Nucl. Instrum. Methods Phys. Res. A 102, 443–450 (1972).

Jia, Q.X. et al. Polymer-assisted deposition of metal-oxide films. Nat. Mater. 3, 529–532 (2004).

Li, D. & Jia, Q.X. US Patent No. 6589457, 08 July 2003.

Lin, Y. et al. Epitaxial growth of Eu2O3 thin films on LaAlO3 substrates by polymer-assisted deposition. Appl. Phys. Lett. 85, 3426–3429 (2004).

Lin, Y. et al. Green luminescent zinc oxide films prepared by polymer-assisted deposition with rapid thermal process. Thin Solid Films 492, 101–104 (2005).

Oganessian, Y. Heaviest nuclei from 48Ca-induced reactions. J. Phys. G. 34, 165–242 (2007).

Oganessian, Yu.Ts. et al. Synthesis of a new element with atomic number Z=117. Phys. Rev. Lett. 104, 142502 (2010).

Stavsetra, L. et al. Independent verification of element 114 production in the 48Ca + 242Pu reaction. Phys. Rev. Lett. 103, 132502 (2009).

Garcia, M.A., Ali, M.N., Parsons-Moss, T., Ashby, P.D. & Nitsche, H. Metal oxide films produced by polymer-assisted deposition (PAD) for nuclear science applications. Thin Solid Films 516, 6261–6265 (2008).

Nuclear Science Advisory Committee. The frontiers of nuclear science, a long range plan (US Department of Energy, Washington, DC and National Science Foundation, Arlington, Virginia, USA, 2007).

Savard, G. & Janssens, R. Proposed ATLAS efficiency and intensity upgrade, ATLAS Workshop (CERN (European Center for Particle Physics), Geneva, 2009).

Podlech, H. et al. A cw heavy ion linac based on superconducting CH-structures (GSI-Accelerators-24). GSI Scientific Report 2008 (GSI Helmholtzzentrum, Darmstadt, Germany, (2009).

Moulson, A.J. Reaction-bonded silicon nitride: its formation and properties. J. Mater. Sci. 14, 1017–1051 (1979).

Garcia, M.A. et al. Heavy-ion irradiation of thulium (III) oxide targets prepared by polymer assisted deposition. Nucl. Instrum. Methods Phys. Res. A 592, 483–485 (2008).

Seidel, H., Csepregi, L., Heuberger, A. & Baumgartel, H. Anisotropic etching of crystalline silicon in alkaline solutions. J. Electrochem. Soc. 137, 3612–3632 (1990).

Schubert, D.W. & Dunkel, T. Spin coating from a molecular point of view: its concentration regimes, influence of molar mass and distribution. Mater. Res. Innov. 7, 314–321 (2003).

Mayerhofer, D. Characteristics of resist films produced by spinning. J. Appl. Phys. 49, 3993 (1978).

Sparrow, E.M. & Gregg, J.L. Mass transfer, flow, and heat transfer about a rotating disk. J. Heat Trans. 82, 294–302 (1960).

Bornside, D.E., Macosko, C.W. & Scriven, L.E. Spin coating: one-dimensional model. J. Appl. Phys. 66, 5185–5194 (1989).

Radspin Ali, M.N., Garcia, M.A., Chang, N.N. & Nitsche, H. Patent pending. (2007).

Acknowledgements

This work was supported by the National Nuclear Security Administration under the Stewardship Sciences Academic Alliance Program, project NS00075, award Number DE-FG52-06NA27480. Work at the Molecular Foundry was supported by the Director, Office of Science, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering, of the US Department of Energy under contract no. DE-AC02-05CH11231.

Author information

Authors and Affiliations

Contributions

All authors contributed extensively to the work presented in this article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Ali, M., Garcia, M., Parsons-Moss, T. et al. Polymer-assisted deposition of homogeneous metal oxide films to produce nuclear targets. Nat Protoc 5, 1440–1446 (2010). https://doi.org/10.1038/nprot.2010.105

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2010.105

- Springer Nature Limited

This article is cited by

-

Improving material properties and performance of nuclear targets for transmutation-relevant experiments

Journal of Radioanalytical and Nuclear Chemistry (2015)