Abstract

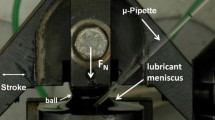

SMOOTH spherical particles have been observed during the microscopic analysis of wear surfaces (ref. 1 and R. S. Miller, personal communication) and of wear particles2 using a new technique called ferrogram developed by Westcott2. These investigators speculated that the spherical particles were produced by cavitation bubbles occurring at the contact surfaces of the bearing. The possibility of cavitation in bearings is well known3; however, it was difficult to understand how these bubbles could produce such perfect microspheres (in the range of 1 to 10 µm in diameter). To verify that cavitation erosion could indeed produce such spheres, we conducted careful experiments with the help of the American Society for Testing and Materials (ASTM) standard vibratory cavitation erosion apparatus; this communication reports the results of this investigation.

Similar content being viewed by others

References

Scott, D., and Mills, G. H., Wear, 16, 234–237 (1970).

Westcott, V. C., Survey of Wear Processes and the Particles Resulting from Wear by means of a Ferrograph, (Trans-Sonics Incorporated Technical Report to Office of Naval Research dated, October 1972).

Thiruvengadam, A., Appl. Mech. Revs, 245–253 (March 1971).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

DOROFF, S., MILLER, R., THIRUVENGADAM, A. et al. Spheroidal particles produced by cavitation erosion. Nature 247, 363–364 (1974). https://doi.org/10.1038/247363a0

Received:

Issue Date:

DOI: https://doi.org/10.1038/247363a0

- Springer Nature Limited

This article is cited by

-

Cavitation–silt erosion in sand suspensions

Journal of Mechanical Science and Technology (2018)