Abstract

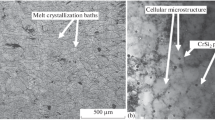

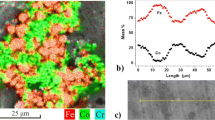

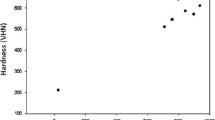

Objects with a fine-scale design of bimetallic beams can display negative thermal expansion. Based on a unit cell design for a negative expansion, produced by Optimal Design methods, we fabricate a thermoelastic “artificial material” using coextrusion of iron and nickel oxides, followed by reductive sintering. A bulk sample with 162 unit cells from Fe-60Ni and Fe-36Ni alloys displayed a thermal expansion coefficient of −3.0 × 10−6/°C, in agreement with the optimal design prediction.

Similar content being viewed by others

References

H. M. Kagaya and T. Soma Solid State Commun. 85 (1993) 617.

T. Suzuki, A. Fijita, T. Chiang and K. Fukamichi Mater. Sci. Engng. A 181/182 (1994) 954.

G. Ernst, C. Broholm, G. R. Kowach and A. P. Ramirez Nature 396 (1998) 147.

A. W. Sleight Ann. Rev. Mater. Sci. 281 (1998) 29.

N. J. Capiati J. Polym. Sci. Polym. Phys. Ed. 151 (1997) 1427.

C. L. Choy, F. C. Chen and E. L. Ong Polymer 20 (1979) 1191.

M. De F. F. Pinheiro, D. J. Radcliffe and H. M. Rosenberg, in Proc. of the Int. Cryog. Eng. Conf., 7th London (1978) p. 494.

G. Hausch, R. Bacher and J. Hartmann Physica B 161 (1998) 22.

J. S. Moya, A. G. Verduch and M. Hortal Trans. J. Brit. Ceram. Soc. 73 (1974) 177.

D. A. Woodcock, P. Lightfoot and R. I. Smith Mater. Res. Soc. Symp. Proc. 547 (1999) 191.

G. L. Belenkii, E. Yu. Salaev, N. A. Suleimanov, N. A. Abdullaev and V. Ya. Shteishraiber Solid State Commun. 53 (1985) 967.

O. Sigmund and S. Torquato J. Mech. Phys. Solids 45 (1997) 1037.

Bing-Chung Chen, “Optimal Design of Material Microstructure and Optimization of Structural Topology for Design-Dependent Loads,” Ph.D. Thesis, Mechanical Engineering, University of Michigan, 2000.

Bing-Chung Chen, Emilio C. N. Silva and N. Kikuchi Intern. J. Numer. Meth. Engng. 52 (2001) 23.

M. P. BendsØe and N. Kikuchi Comp. Meth. Appl. Mech. Engng. 71 (1988) 197.

Y. Tanji J. Phys. Soc. Japan 31 (1975) 1366.

C. Van Hoy, A. Barda, M. Griffith and J. W. Halloran J. Amer. Ceram. Soc. 81 (1998) 152.

A. T. Crumm and J. W. Halloran ibid. 81 (1998) 1053.

A. T. Crumm, “MicroFabrication by Coextrusion,” Ph.D. Dissertation University of Michigan, 2000.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Qi, J., Halloran, J.W. Negative thermal expansion artificial material from iron-nickel alloys by oxide co-extrusion with reductive sintering. Journal of Materials Science 39, 4113–4118 (2004). https://doi.org/10.1023/B:JMSC.0000033391.65327.9d

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000033391.65327.9d