Abstract

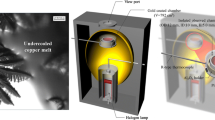

High-temperature optical microscopy is an essential in situ characterisation and monitoring technique with wide applications in different areas of materials science. The devices used include commercial available instruments, known as heating microscopes, and custom-made devices, usually called “high-temperature processing microscopes” or “thermo-optical instruments”. The different areas of applications of high-temperature optical microscopy are discussed on the basis of practical examples drawn from the literature. Besides the classical use of the technique to study the melting and softening behaviour of glass, slags, ashes and other silicate and ceramic materials, this review covers alternative applications, in particular the use of heating microscopes as “optical dilatometers” to investigate the sintering kinetics of powder compacts. In this regard, the advantages of the technique over conventional dilatometry are emphasised. A variety of custom-made devices is described, developed to investigate particular problems, such as delamination and curling of laminate composites during densification, cosintering of multilayer metal-ceramic and ceramic-ceramic systems, and wetting behaviour of liquid phases on rigid substrates. As a particular example of such a custom-made equipment, a novel, multi-purpose high-temperature processing microscope is described, and its application potential, which is well beyond that of commercial devices, is outlined. This instrument is unique in that it combines both vertical and horizontal sample observation capability, as well as the possibility to investigate samples of relatively large sizes (65 mm3), i.e. about 10 times larger than those suitable for commercial heating microscopes.

Similar content being viewed by others

References

E. M. Chamot and C. W. Mason, in “Handbook of Chemical Microscopy,” Vol. I, 2nd ed. (John Wiley & Sons, New York, 1938) pp. 198–204.

R. Clevenger, Ind. Eng. Chem. 16 (1924) 854.

P. K. Gallagher, in “Thermal Characterisation of Polymeric Materials,” Vol. 1, 2nd ed., edited by E. A. Turi (Academic Press, San Diego, 1997) pp. 149–155.

P. A. Tick, K. E. Lu, S. Mitachi, T. Kanamori and S. Takahashi, J. of Non-Cryst. Solids 140 (1992) 275–280.

R. J. Miller and H. F. Gleeson, Meas. Sci. Technol. 5 (1994) 904–911.

E. M. Daver and W. J. Ullrich, in “Experimental Techniques in Powder Metallurgy,” edited by J. S. Hirschhorn and K. H. Roll (Plenum Press, New York, 1970) pp. 189–200.

F. A. Costa Oliveira, R. J. Fordham, S. Canetoli and J. H. W. De Wit, Key Eng. Mat. 113 (1996) 91–98.

Y. Maeda and M. Koizumi, Rev. Sci. Instrum. 67 (1996) 2030–2031.

Linkam Scientific Instruments: Heating and Freezing Stages, Product Information, 1998.

D. M. Price, European Microscopy and Analysis 53(5) (1998) 21–23.

B. E. Dom, H. E. Evans and D. M. Torres, in “Adhesion Aspects of Polymeric Coatings,” edited by K. L. Mittal (Plenum Press, New York, 1983) pp. 597–612.

“Materials Science and Technology, Vol. 2B: Characterisation of Materials,” edited by R. W. Cahn, P. Haasen and E. J. Cramer. (Wiley-VCH, 1993).

“Handbook of Microscopy, Applications in Materials Science, Solid-State Physics and Chemistry,” edited by S. Amelinckx, D. van Dyck, J. van Landuyt and G. van Tendeloo (VCH, Weinheim, 1997).

ASM Handbook, Vol. 17, Nondestructive Evaluation and Quality Control (ASM International, Ohio, 1989).

Leica Mikroskopie und Systeme GmbH, LEITZ Heating Microscopes, Product Information N. 913661. Leica Mikroskopie und Systeme GmbH, Wetzlar (Germany).

Misura 2.0: Automatic Heating Microscope with Integrated Image Analysis, Product Information. Expert System srl, Modena (Italy).

W. Radmacher, Brensstoff-Chemie 30 (1949) 377–384.

K. H. Endell, Z. Krist. 56 (1921) 191.

E. Ebert, Organ f¨ur die Forstschritte des Eisenbahnwesens 85 (1930) 410.

W. Mann, Ber. Deutsch. Keram. Gesell. 29 (1952) 163–168.

S. Schor, Energie 8 (1956) 2–4.

A. Zwetsch, Ber. Deutsch. Keram. Gesell. 33 (1956) 349–357.

A. Metz, Radex-Rundschau 4 (1959) 612–616.

R. GÖrke and K.-J. Leers, Keramische Zeitschrift 48 (1996) 300–305.

A. Metz, Keram. Zeitschrift 6 (1962) 351–354.

B. Luthard, Fa. Leica,Wetzlar (Germany), personal communication (1998).

A. Metz, Silikat-Journal 3 (1964) 273–278.

H. Scholze, Ber. Dtsch. Keram. Ges. 39 (1962) 63–68.

H. Jebsen-Marwedel, Glastech. Ber. 27 (1954) 172–173.

H. S. Kim, R. D. Rawlings and P. S. Rogers, J. Mater. Sci. 24 (1989) 1025–1037.

T.-F. Lee and Y.-C. Ko, Ceram. Bull. 61 (1982) 737–740.

I. Vicente Magarino, J. Ma. RincÓn, P. Bowles, R. D. Rawlings and P. S. Rogers, Glass Technol. 33 (1992) 49–52.

H. J. Padberg, cfi/Ber. DKG 70 (1993) 598–602.

D. S. Buist, Br. Ceram. Soc. Trans. 69 (1970) 15–20.

R. Conradt, in “Proc.HVG/NCNGColloquium: Melting Processes in Glass Furnaces,” edited by H. A. Schaeffer and R. G. C. Beerkens (German Glass Society (DGG) 1998).

E. Gugel Und F. Czedik-Eysenberg, Berg-und h¨uttenmännische Monatsh. 105 (1960) 201–210.

K. H. Clemens, Mitt. VDEfa 9 (1961) 97–108.

E. Hofmann, Stahl und Eisen 79 (1959) 846–854.

F. Reich and J. D. Panda, TIZ-Zbl. 85 (1961) 186–190.

Idem., Tonindustrie-Zeitung 85 (1961) 223–229.

F. Zapp and I. Domagala, Keramische Zeitschrift 6 (1954) 505–508.

K. Spangenberg, Silikatechnik 5 (1954) 330.

F. Freund, Ber. Dtsch. Keram. Ges. 37 (1960) 209–218.

R. M. German, “Sintering Theory and Practice” (John Wiley & Sons, New York, 1996).

O. S. Ozgen and G. M. Fryer, Trans. Br. Ceram. Soc. 80 (1981) 67–70.

X. Elias and A. Viedma, Keram. Zeitschrift 32 (1984) 420–425.

D. Harkort and D. Paetsch, Ber. Dtsch. Keram. Ges. 37 (1960) 402–409.

H. E. Exner, Powd. Metall. 4 (1980) 203–209.

K.-D. Kim, J. Mat. Res. 10 (1995) 1846–1849.

L. C. Dejonghe and M. N. Rahaman, Rev. Sci. Instrum. 55 (1984) 2007–2010.

M. N. Rahaman, L. C. Dejongue, G. W. Scherer and R. J. Brook, J. Amer. Ceram. Soc. 70 (1987) 766–780.

A. R. Boccaccini, Science of Sintering 23 (1991) 151–161.

U. Partsch, C. Kretzschmar, E. K. Polzer, P. Otschlik, J.-H. Meyer, in “Werkstoffwoche 96: Werkstoffe f¨ur die Informationstechnik,” edited by H. Thomann (DGM Informationsgesellschaft, Oberursel, 1997) pp. 139–144.

Z. Panek, J. Mater. Sci. 29 (1994) 5383–53889.

W. S. Hackenberger, T. R. Shrout and R. F. Speyer, in “Sintering Technology,” edited by R. M. German, G. L. Messing and R. G. Cornwall (Marcel Dekker, New York, 1996) pp. 505–512.

M. Paganelli, Ind. Ceram. 16 (1996) 1–6.

M. Ferraris and E. Verne, J. Europ. Ceram. Soc. 16 (1996) 421–427.

E. VernÉ, M. Ferraris, A. Ventrella, L. Paracchini, A. Krajewski and A. Ravaglioli, J. Europ. Ceram. Soc. 18 (1998) 363–372.

A. P. N. Deoliveira, T. Manfredini, L. Barbieri, C. Leonelli, G. P. Pellacani, J. Amer. Ceram. Soc. 81 (1998) 777–780.

A. R. Boccaccini, J. Mater. Sci., 29 (1994) 4273–4278.

A. R. Boccaccini, P. A. Trusty and D. M. R. Taplin, Mater. Lett. 24 (1995) 199–205.

A. R. Boccaccini and R. Kramer, Glass Technology 36 (1995) 95–97.

A. R. Boccaccini, Microscopy and Analysis 57 Nr. 1 (1997) 19–20.

Idem., J. Mater. Sci. Lett. 12 (1993) 943–945.

A. R. Boccaccini, W. Stumpfe, D. M. R. Taplin and C. B. Ponton, Mat. Sci. Eng. A219 (1996) 26–31.

H. Schreiner and R. Tusche, Powder Metall. Int. 11 (1979) 52–56.

H. E. Exner and E. A. Giess, J. Mater. Res. 3 (1988) 122–125.

M. J. Hoffmann, A. Nagel, P. Greil and G. Petzow, J. Amer. Ceram. Soc. 72 (1989) 765–769.

A. R. Boccaccini, in Proceedings 4th ESG Conference, Fundamentals of Glass Science and Technology (The Glass Research Institute, Växjö, Sweden, 1997) pp. 356–363.

A. Cyunczyk, Powd. Metall. Int. 11 (1979) 162–164.

Y. Wanibe, N. Fujitsuna, T. Itoh and H. Yokohama, Powd. Metall. 32 (1989) 191–194.

R. Raman, R. M. German, Met. Mat. Trans. 26A (1995) 653–660.

Y. Mizuno, A. Kawasaki and R. Watanabe, Powd. Metall. 38 (1995) 191–195.

A. P. Bromley, G. Wood and R. Fletcher, Ceram. Bull. 77 (9) (1998) 58–62.

M. N. Rahaman and L. C. Dejonghe, J. Amer. Ceram. Soc. 70 (1987) C-348–C-351.

G. W. Scherer, Ceram. Bull. 70 (1991) 1059–1063.

A. R. Boccaccini, Adv. Comp. Lett. 4 (1995) 143–149.

S. Winkler, P. Davies, J. Janoschek, J. Thermal Analysis 40 (1993) 999–1008.

A. Jagota, K. R. Kikeska and R. K. Bordia, J. Amer. Ceram. Soc. 73 (1990) 2266–2273.

A. R. Boccaccini and E. A. Olevsky, Met. Mat. Trans. 28A(11) (1997) 2397–2404.

A. R. Boccaccini, J. Mater. Res. 13(6) (1998) 1693–1697.

T. Takamori and K. Iriyama, Ceram. Bull. 46 (1967) 1169–1173.

M. N. Rahaman, L. C. Dejonghe, S. L. Shinde and P. H. Tewari, J. Amer. Ceram. Soc. 71 (1988) C-338–C-341.

R. E. Dutton and M. N. Rahaman, ibid. 75 (1992) 2146–2154.

M. Y. Nazmy, Powder Metall. Int. 8 (1976) 19.

M. Borbe, A. BÜrger, E. Hornbogen and H. NÖcker, Materialpr¨ufung 36 (1994) 418–421.

Z. Chen, S.-F. Chen, R. A. Overferth and M. F. Rose, J. Mater. Res. 13 (1998) 2202–2205.

M. A. Nettleton and E. Raask, J. Appl. Chem. 17 (1967) 18–21.

E. Raask and R. Jessop, Phys. Chem. Glasses 7 (1966) 200–201.

C. K. Schoff, in “Modern Approaches to Wettability. Theory and Applications,” edited by M. E. Schrader and G. L. Loeb (Plenum Press, New York, 1992) p. 375.

W. F. Gale, J. W. Fergus, W. M. Ingram and M. Koopman, J. Mater. Sci. 32 (1997) 4931–4940.

K. Lellig, Untersuchung der Benetzung und Haftung bei Verbundwerkstoffen aus Gläsern und thermoplastischen Polymeren, Dissertation, Aachen University of Technology, Aachen, Germany, 1996.

E. Kuhn, B. Hamann and D. HÜlsenberg, Glas und temperaturbeständige, glaskristalline Erzeugnisse auf der Basis von recyceltem, verunreinigtem Flachglas. Final Report Nr. B403-96003. Technical University of Ilmenau, Ilmenau, Germany (1997).

Carbolite GmbH, Laboröfen, Trocken-und Brötschränke. Product Information, Carbolite GmbH (1998) p. 19.

S. Mäkipirtti, in “Powder Metallurgy,” edited by W. Leszynski (Interscience Publishers, New York, 1960) pp. 97–111.

M. Tikkanen, Planseeberichte f¨ur Pulvermetallurgie 11 (1963) 70–81.

G. A. Shoales and R. M. German, Met. Mat. Trans. 29A (1998) 1257–1263.

Y Mizuno, A. Kawasaki and R. Watanabe, Metall. Mat. Trans. 26B (1995) 75–79.

A. Siegmann, I. Raiter, M. Narkis and P. Eyerer, J. Mater. Sci. 21 (1986) 1180–1186.

C. T. Bellehumeur, M. K. Bisaria and J. Vlachopoulos, Polym. Eng. Sci. 36 (1996) 2198–2207.

L. Sarvaranta, J. App. Polym. Sci. 56 (1995) 1085–1091.

C. P. Ostertag, in “Science of Sintering,” edited by D. P. Uskokovic, H. Palmour III and R. M. Spriggs (Plenum Press, New York, 1989) pp. 453–459.

C. P. Ostertag, J. Amer. Ceram. Soc. 70 (1987) C-355–C-357.

P. Z. Cai, D. J. Green and G. L. Messing, ibid. 80 (1997) 1929–39.

T. Cheng and R. Raj, ibid. 71 (1988) 276–280.

Idem., ibid. 72 (1989) 1649–1655.

G.-Q. Lu, R. C. Sutterlin and T. K. Gupta, ibid. 76 (1993) 1907–14.

J. Bang and G.-Q. Lu, J. Mater. Res. 10 (1995) 1321–1326.

J.-H. Jean and C.-R. Chang and Z.-C. Chen, J. Amer. Ceram. Soc. 80 (1997) 2401–2406.

J.-H. Jean and C.-R. Chang, ibid. 80 (1997) 3084–92.

T. J. Garino and H. K. Bowen, ibid. 73 (1990) 251–257.

J. N. Calata, A. Matthys and G.-Q. Lu, J. Mater. Res. 13 (1998) 2334–2341.

F. Raether and G. MÜller, in “Fourth Euroceramics,” Vol. 2, edited by C. Galassi (Faenza Editrice, 1995) pp. 103–112.

B. J. Carroll, in “Contact Angle,Wettability and Adhesion,” edited by K. L. Mittal (VSP, Utrecht, The Netherlands, 1993) pp. 235–246.

F. Boury and J.-E. Proust, ibid. (1993) pp. 585–595.

V. K. Nagesh, A. P. Tomsia and J. A. Pask, J. Mater. Sci. 18 (1983) 2173–2180.

H. J. Oel, Ber. Dtsch. Keram. Ges. 38 (1961) 258–267.

H.-N. Ho, S.-T. Wu, Mat. Sci. Eng. A248 (1998) 120–124.

S. W. Ip, R. Sridhar, J. M. Toguri, T. F. Stephenson, A. E. M. Warner, ibid. A244 (1998) 31–38.

A. Feng, B. J. Mccoy, Z. A. Munir, D. Cagliostro, ibid. A242 (1998) 50–56.

E. Saiz and A. P. Tomsia, J. Amer. Ceram. Soc. 81 (1998) 2381–2393.

K. Landry, S. Kalogeropoulou, N. Eustathopoulos, Mat. Sci. Eng. A254 (1998) 99–111.

J. C. Bacri, R. Perzynski, D. Salin, F. Brochard-Wyart, J. M. Di Meglio, D. Quere, in “Hydrodynamics of Dispersed Media,” edited by J. P. Hulin, A. M. Cazabat, E. Guyon and F. Carmona (North Holland, Amsterdam, 1990) pp. 63–68.

W. D. Kingery, J. Amer. Ceram. Soc. 42 (1959) 6–10.

P. Nikolopoulos and G. Ondracek, Z. Werkstofftechnik 13 (1982) 60–69.

C. A. Deckert and D. A. Peters, in “Adhesion Aspects of Polymeric Coatings,” edited by K. L. Mittal (Plenum Press, New York, 1983) pp. 469–480.

R. Nitsche, Zur Benetzung und Haftung von Verbundwerkstoffphasen und Metall-Keramik-Systemen. Dissertation, Aachen Technical University, Aachen, Germany (1994).

Thermal Technology, Reaction Monitoring Display System. Product Information, Thermal Technology, Inc. Santa Rosa, USA.

B. Hamann and W. Gruner,Vorrichtung zur Untersuchung thermischerVorgänge anWerkstoffproben. Patentanmeldung (Germany) DE 198 15 827.0. 9.4.98.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boccaccini, A.R., Hamann, B. Review In Situ high-temperature optical microscopy. Journal of Materials Science 34, 5419–5436 (1999). https://doi.org/10.1023/A:1004706922530

Issue Date:

DOI: https://doi.org/10.1023/A:1004706922530