Abstract

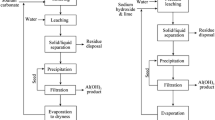

This research presents an alternative method for scandium (Sc) recovery from impure bauxite residue solutions containing Fe(III), Al, Ca, Nd, and Y through the use of hydroxide and phosphate precipitation. Among hydroxide donors, ammonia solution removed the most Fe(III) from solution, while co-precipitation of other elements in the synthetic pregnant leach solution remained negligible. When using dibasic phosphate as the precipitant, in the pH range of 1.5–2.5, both Sc and Fe were removed rapidly, while co-precipitation of other ions remained low. Experimental results were used to propose the preliminary design of a three-stage precipitation process capable of producing a scandium product from highly impure process solutions.

Similar content being viewed by others

References

Lathabai S, Lloyd P (2002) The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al–Mg alloy. Acta Mater 50(17):4275–4292

Lee S, Utsunomiya A, Akamatsu H, Neishi K, Furukawa M, Horita Z, Langdon T (2002) Influence of scandium and zirconium on grain stability and superplastic ductilities in ultrafine-grained Al–Mg alloys. Acta Mater 50(3):553–564

Marquis E, Seidman D (2001) Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys. Acta Mater 49(11):1909–1919

Ormerod RM (2003) Solid oxide fuel cells. Chem Soc Rev 32(1):17–28

Yamamoto O (2000) Solid oxide fuel cells: fundamental aspects and prospects. Electrochim Acta 45(15):2423–2435

Feuling RJ (1991) Recovery of scandium, yttrium and lanthanides from titanium ore. US Patent 5,049,363

Gongyi G, Yuli C, Yu L (1988) Solvent extraction off scandium from wolframite residue. JOM 40(7):28–31

Wang W, Cheng CY (2011) Separation and purification of scandium by solvent extraction and related technologies: a review. J Chem Technol Biotechnol 86(10):1237–1246

Wang W, Pranolo Y, Cheng CY (2011) Metallurgical processes for scandium recovery from various resources: a review. Hydrometallurgy 108(1):100–108

Power G, Gräfe M, Klauber C (2011) Bauxite residue issues: I. Current management, disposal and storage practices. Hydrometallurgy 108(1):33–45

Borra CR, Pontikes Y, Binnemans K, Van Gerven T (2015) Leaching of rare earths from bauxite residue (red mud). Miner Eng 76:20–27

Ochsenkühn-Petropoulou MT, Hatzilyberis KS, Mendrinos LN, Salmas CE (2002) Pilot-plant investigation of the leaching process for the recovery of scandium from red mud. Ind Eng Chem Res 41(23):5794–5801

Ochsenkühn-Petropulu M, Lyberopulu T, Ochsenkühn K, Parissakis G (1996) Recovery of lanthanides and yttrium from red mud by selective leaching. Anal Chim Acta 319(1):249–254

Wang W, Pranolo Y, Cheng CY (2013) Recovery of scandium from synthetic red mud leach solutions by solvent extraction with D2EHPA. Sep Purif Technol 108:96–102

Ochsenkühn-Petropulu M, Lyberopulu T, Parissakis G (1995) Selective separation and determination of scandium from yttrium and lanthanides in red mud by a combined ion exchange/solvent extraction method. Anal Chim Acta 315(1):231–237

Horovitz CT (2012) Scandium its occurrence, chemistry physics, metallurgy, biology and technology. Academic Press, London

Chen PL, Chen IW (1993) Reactive cerium (IV) oxide powders by the homogeneous precipitation method. J Am Ceram Soc 76(6):1577–1583

Li JG, Ikegami T, Mori T, Yajima Y (2004) Sc2O3 nanopowders via hydroxyl precipitation: effects of sulfate ions on powder properties. J Am Ceram Soc 87(6):1008–1013

Stevenson PC, Nervik WE (1961) The radiochemistry of the rare earths: scandium, yttrium, and actinium, vol 3020. National Academies, Washington, DC

Vickery RC (1960) The chemistry of yttrium and scandium, vol 2. Pergamon Press, Oxford

Firsching FH, Brune SN (1991) Solubility products of the trivalent rare-earth phosphates. J Chem Eng Data 36(1):93–95

Liu X, Byrne RH (1997) Rare earth and yttrium phosphate solubilities in aqueous solution. Geochim Cosmochim Acta 61(8):1625–1633

Lucas S, Champion E, Bregiroux D, Bernache-Assollant D, Audubert F (2004) Rare earth phosphate powders RePO4·nH2O (Re = La, Ce or Y)—part I. Synthesis and characterization. J Solid State Chem 177(4):1302–1311

Beltrami D, Deblonde GJ-P, Bélair S, Weigel V (2015) Recovery of yttrium and lanthanides from sulfate solutions with high concentration of iron and low rare earth content. Hydrometallurgy 157:356–362

Acknowledgments

The research leading to these results has received funding from the European Community’s Horizon 2020 Programme ([H2020/2014–2019]) under Grant Agreement No. 636876 (MSCA-ETN REDMUD). This publication reflects only the author’s view, exempting the Community from any liability. Project website: http://www.etn.redmud.org.

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was Yiannis Pontikes.

Rights and permissions

About this article

Cite this article

Yagmurlu, B., Dittrich, C. & Friedrich, B. Precipitation Trends of Scandium in Synthetic Red Mud Solutions with Different Precipitation Agents. J. Sustain. Metall. 3, 90–98 (2017). https://doi.org/10.1007/s40831-016-0098-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-016-0098-9