Abstract

The present work is a survey on aircraft hybrid electric propulsion (HEP) that aims to present state-of-the-art technologies and future tendencies in the following areas: air transport market, hybrid demonstrators, HEP topologies applications, aircraft design, electrical systems for aircraft, energy storage, aircraft internal combustion engines, and management and control strategies. Several changes on aircraft propulsion will occur in the next 30 years, following the aircraft market demand and environmental regulations. Two commercial areas are in evolution, electrical urban air mobility (UAM) and hybrid-electric regional aircraft. The first one is expected to come into service in the next 10 years with small devices. The last one will gradually come into service, starting with small aircraft according to developments in energy storage, fuel cells, aircraft design and hybrid architectures integration. All-electric architecture seems to be more adapted to UAM. Turbo-electric hybrid architecture combined with distributed propulsion and boundary layer ingestion seems to have more success for regional aircraft, attaining environmental goals for 2030 and 2050. Computational models supported by powerful simulation tools will be a key to support research and aircraft HEP design in the coming years. Brazilian research in these challenging areas is in the beginning, and a multidisciplinary collaboration will be critical for success in the next few years.

Similar content being viewed by others

1 Introduction

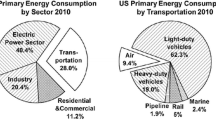

Since the introduction of jet engines, the air transport industry has doubled its size every 20 years, the highest rate in transport sector, and it is expected to continue in a similar rate in the next years. However, its environmental impact in terms of noise and pollutant emissions has gained public attention (IATA 2019).

In addition, the foreseen financial benefits of increased energy efficiency have motivated the transport industry to invest in propulsion alternatives (IATA 2019). Whereas air transport industry is responsible for a considerable part of greenhouse gas emissions, a concept where ICEs and electric motors (EM) are combined in the propulsion to increase vehicle efficiency and reduce the impact is being analyzed (Zhang et al. 2016). This alternative has been called by some authors hybrid-electric propulsion (HEP) (Hung and Gonzalez 2012).

This hybridization can be achieved combining ICEs or FCs with EMs and batteries (González Espasandín et al. 2014). Some of the main advantages of HEP compared with the traditional propulsion are: (a) increasing the global aircraft efficiency; (b) increasing aircraft reliability, power distribution/quality, and flight range; (c) emissions and noise reduction; (d) capacity of extending the market to smaller airports (Sliwinski et al. 2017).

Hybrid-electric propulsion system (HEPS) appears as the most viable solution for an energy efficient, cleaner and quieter aeronautical propulsion, since it is able to combine the advantages of the conventional propulsion system and the all-electric approach (Sliwinski et al. 2017). Despite this, several goals must be achieved to make the technology viable. NASA’s Subsonic Fixed Wing project identified four “corners” to be overcome: noise, emissions, aircraft fuel burn, and field length (Kim et al. 2008).

Recent advances in electrical motors, energy storage systems, and power electronics converters (PEC) are leading the aircraft propulsion to become increasingly electrical (Sliwinski et al. 2017). The concept More Electric Aircraft (MEA) aims for changing the aircraft systems to be fully powered by electricity. Currently, only monitoring devices and auxiliary systems are electrical, while more powerful devices still work with hydraulic or thermal systems (Buticchi et al. 2017). Despite this, since 2010 developments with all-electrically propelled aircraft have augmented, even faster from 2016, especially in the area of urban air vehicles (UAVE) (IATA 2019).

The hybrid-electric propulsion offers operational flexibility, due to the greater number of components. Fuel and battery sources allow more possibilities for managing of the propulsion system in the various stages of a mission, and reduce the energy consumption, compared with traditional. However, it implies an increase in the necessary load during the design phase, and a greater complexity in the operation. Proper management of the electrical components and combustion is mandatory to meet the environmental requirements and reduce the fuel consumption (Riboldi 2019).

Aircraft propulsion will gradually evolve from small all-electric UAVEs in the beginning, to medium size hybrid-electric aircraft, and later to HEP regional aircraft in a lapse of three decades. The study of HEPS requires a multidisciplinary combined approach to cope with all the related areas, a challenging task to cope with. This present work is a survey that depicts the state-of-art development in HEP identifies the most challenging requirements in the short and mean times, resumes the different approaches and alternatives, and points the paths of future research.

2 Civil Aviation Market

Civil global aviation market has experienced a considerable economic growth in recent years, and will keep increasing. It is estimated that around 1300 new international airports will be required, and the commercial aircraft fleet will double by 2050 (IATA 2017; Liu 2013). Brazil has a considerable stake in this increment, since it is the second country in the world in the amount of airports, and the third domestic commercial market with 22,340 registered aircraft (ANAC 2019b, a).

The aeronautical sector generates considerable greenhouse gas emissions, 781 million tons of \(\hbox {CO}_2\) were emitted in 2015 (ATAG 2018). With no intervention by 2050 aviation emissions could grow by 300–700% (ICAO 2016a). Since aviation industry account for 2% of total \(\hbox {CO}_2\) emissions worldwide, international aviation organizations aim to achieve carbon neutral growth from 2020, and to reduce its emissions by 50% by 2050 compared to 2005 levels (ICAO 2016b). A target for civil aviation set by ACARE (Advisory Council for Aviation Research and Innovation in Europe) for 2050 demands a reduction of 75% in \(\hbox {CO}_2\) emissions, 90% in \(\hbox {NO}_x\), and 65% in noise compared to 2000 levels (Table 1) (ACARE 2018). These objectives will not be achieved with conventional technologies.

NASA N+3 goals aim to reduce noise in 71 dB, \(\hbox {NO}_x\) emissions in 75%, and fuel burn in 70% compared with 2005 levels, with timeframe of 2030–2035 (Bruner et al. 2010). Other programs such as CLEEN in the USA, GARDN in Canada, Clean Sky and Clean Aviation in the European Union (EU) focus in developing certifiable aircraft technology for fuel consumption reduction, silent flying, and reduced emissions (IATA 2019).

To attend this increasing demand and environmental regulations, revolutionary airplane concepts are needed, to reduce the takeoff and landing noise on urban areas around the airports, to decrease the energy consumption and emissions, while remaining economically viable. Large airports with runways longer than 3050 m are heavily utilized, while thousands of smaller airports with runways shorter than 910 m are underutilized (Kim et al. 2008). These new aircraft concepts with architectures that increase propelling torque and power, for shorter takeoff distances, can enable future devices to utilize smaller airports (Liu 2013). The HEPS is an evolution where small planes can use airfields with smaller runways for commercial applications. Electric motors have higher torque at low speeds, making the aircraft’s acceleration during takeoff to be higher (Riboldi 2019). In Brazil, 98% of air traffic is concentrated in 65 airports, about 2.6% of the 2, 499 airports nationwide (Infrastructure Ministry of Brazil 2017). These flight profiles are estimated ideal for future all-electric or HEP aircraft.

Nordic countries are pointing to sustainable air travel, aiming for short-haul flights and domestic 100% electric air travel until 2045. This time is needed since an electric airplane requires to define charging standards, new infrastructure, and new business models (Welstead et al. 2017).

Airports as Schiphol in Amsterdam encourage the use of quiet and clean aircraft, while flag that infrastructure adjustments with additional energy supply might be required for electric aircraft, for battery storage and shipping. Airline companies like Harbour Air, that employ aircraft with less than 30 passengers expect to electrify its fleet in the next years, aiming to reduce emissions and operational costs. Small European airlines like SAS, Widerøe and EasyJet have also initiated partnership to develop HEP aircraft for around 50 passengers (Berger 2020).

Aircraft electric propulsion (EP) will influence the aviation business on the airports. A potential reduction of 50% in aircraft maintenance costs is expected with expansion of electric aircraft, as well as savings on the cost of standard fuel (Welstead et al. 2017).

2.1 Urban Air Mobility

The expected penetration of EP aircraft into the market would start with 1–2 passengers all-electric urban air taxis (UAT) until 2025, 15–20 passengers HEP aircraft from 2025 to 2030, and battery or FC powered aircraft from 2035 to 2045 (IATA 2019). The first HEP aircraft with more than 50 seats is expected by 2032 (Berger 2020).

The introduction of EP is revolutionary in the aviation industry (IATA 2019). It has been developed since the 1970s, at the beginning there were unmanned demonstrators with small batteries and EMs with power of a few kilowatts. The market availability of lithium-ion (Li-Ion) and lithium-polymer batteries (Li-Po) since 2001 was a milestone for EP, because of the higher battery energy density (BED) (Brelje and Martins 2019; Linden and Reddy 2001).

UAM is a safe and efficient system for air passenger and cargo transportation within an urban area, aiming to decongest the road traffic, improve mobility, reduce transport time and decrease pollution. The main applications are on airport shuttle, taxi, ambulance, police and other first response public services, in which small-size (less than 5 passengers) electric and hybrid vertical and takeoff landing (VTOL) vehicles, are being considered (Goyal 2018).

UAM would provide public access to aerial transportation within metropolitan areas. Research projects had received high investments, most of them for all-electric VTOLs (eVTOL) (Gnadt et al. 2019). Predictions state that flying taxis and air package delivery will entry-into-service (EIS) in the US market by 2023 (Swaminathan and Cao 2020). A market of USD$2.5 bn is expected in the first years of operation in the USA, with a total available market of USD$500 bn (Goyal 2018).

However, to become a reality this technology must face challenges such as approving regulations and standards, obtaining redundancy certifications, dealing with the weather conditions, and installing the urban infrastructure. Actual concepts involving VTOLs are quiet and would work for flight times between 15 and 45 min, but recharging availability must be analyzed. Another issue is that VTOLs have high power demand at the beginning and end of a flight. This technology still holds high certification risk and failure modes, since it doesn’t have actuator redundancy or glide capability. Most of them require high BED, able to suffer thermal failures, which raises certification concerns. Social barriers related to safety, privacy and noise must also be analyzed. A strong cooperation between governments and aircraft industry to overcome these issues will be needed (Goyal 2018; Gnadt et al. 2019; Amelang 2018).

Short takeoff and landing (STOL) aircraft seem to be a more-easily certifiable solution for UAM, since takeoff and landing are similar to conventional aircraft, but in a shorter distance, and are capable of gliding for emergency landing. STOL generally may achieve longer range and faster cruising speed (Gnadt et al. 2019).

Many start-ups and manufacturers are developing UAVE designs. Volocopter is a two seats, VTOL multi-copter, able to fly up to 27 km at 70 km/h (Lenton 2018). Lilium Jet works on a eVTOL for two persons and an autonomy up to 300 km. Joby Aviation, Zee Aero and Kitty Hawk are working in other VTOL concepts, where the range is limited by the specific BED of batteries, while a HEP approach is considered to extend this range (Bacchini and Cestino 2019; Misra 2018).

Boeing NeXt program developed the passenger air vehicle prototype, an eVTOL with a range up to 80 km (Hilfer 2019). An eight-propeller aircraft concept with eVTOL is part of the EmbraerX approach (EmbraerX 2019).

3 Aircraft Hybrid-Electric Propulsion

HEP is considered an effective substitute for conventional short and medium-range aircraft, and companies as Airbus, Siemens, Rolls-Royce and Boeing are strongly investing in this technology (IATA 2019).

Five categories are defined for HEP architectures: series hybrid, parallel hybrid, series/parallel hybrid, turbo-electric hybrid, and all-electric (IATA 2019). Some variation of hybrid topologies use FCs instead of ICEs. Each architecture has its own characteristics related to energy efficiency, application, complexity and technical challenges (Dean et al. 2018). DP is a concept that combined with some of these architectures may render advantages from the synergy.

3.1 Series Hybrid Architecture

In series hybrid architecture, depicted in Fig. 1, only the EMs are mechanically connected to the fans. The ICE drives an electric generator, which electrical output drives the motor or charges the batteries with the help of PECs. In flight phases that require low propulsive effort (e.g., cruise phase), the energy converted by the generator may also recharge the batteries. Series architecture can be combined with DP concepts (National Academies of Sciences, Engineering and Medicine 2016).

The main advantage of the series architecture is that the ICE is not mechanically coupled to thrust generation, and thus can constantly run in its best operating power and speed. Additionally, the simplicity of the concept leads to an easy propulsion control. As a disadvantage, the EM has to provide the entire propulsion power alone, so that it needs to be specified for the maximum power, which represents more weight in the drivetrain (Ehsani et al. 2004).

The series configuration is suitable for high-torque, low-speed applications, but is less efficient than parallel. It also requires larger batteries and electrical machines, increasing the mass and volume of the powertrain (Donateo et al. 2018).

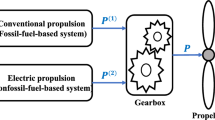

3.2 Parallel Hybrid Architecture

In parallel hybrid architecture, depicted in Fig. 2, there are two parallel propulsion shafts, powered by combustion and electric sources, which are mechanically coupled. Battery-powered EM and ICE shafts are both coupled to a shaft that drives a fan or propeller, so either or both can provide propulsion (National Academies of Sciences, Engineering and Medicine 2016). This hybrid architecture also allows charging the batteries, when the ICE drives the propeller and the EM through the coupling. In this case, the EM operates as an electric generator.

Differently from series and series-parallel, there is no electric generator on the ICE’s shaft, and machines may be sized smaller since the propelling power is provided by both, with corresponding weight reduction (Wall and Meyer 2020). The disadvantages of this configuration are the extra mass by the mechanical coupling, and the need for a more sophisticated propulsion control system. Additionally, the ICE’s operation may be less optimal in different flight stages than in a series configuration, since it is involved in thrust generation (Schoemann 2014).

Table 2 summarizes series and parallel configurations main characteristics and presents a comparison between them.

3.3 Series/Parallel Hybrid Architecture

This architecture is a combination of the two described before. As depicted in Fig. 3, ICE, EM, electric generator and propeller are mechanically connected through a coupling. Thus, the ICE’s mechanical power may be used to drive the propeller or converted into electric power by a generator to charge the batteries.

The main advantage of this configuration is that it allows an easy topology change during operation, and is the most used architecture in hybrid vehicles. As a disadvantage, this architecture presents a high level of complexity on control and weight estimation (Ehsani et al. 2004).

Some concepts are testing a variation of this architecture combined with DP, in which one or more fans are mechanically driven by ICEs, while others exclusively by EMs, which are powered by a battery package or by the ICE-driven electrical generator (National Academies of Sciences, Engineering and Medicine 2016).

3.4 Turbo-Electric Hybrid Architecture

This architecture is similar as series but do not rely on batteries for propulsion energy, and several HEP concepts employ it due to the actual low BED. The ICE drives an electric generator and PECs with EM drive electric a fan or propeller. All the power comes from the fuel, and there are no additional energy storage devices (Welstead and Felder 2016; National Academies of Sciences, Engineering and Medicine 2016). The same way as in series, decoupling the ICE propulsive from the EM thrust-producing devices enables higher performance in the propulsion, and design flexibility in the aircraft. ICEs may operate close to its peak efficiency power vs. speed conditions, and can be located at optimum locations in the aircraft (Welstead and Felder 2016; Kim et al. 2008).

This architecture is well suited to combine with DP concepts, where the power is distributed to several EM-driven fans, positioned to provide synergistic integration in the airframe, and also with superconducting electrical systems. Power lost in energy conversion from mechanical to electrical and reverse is overcome with distributed fans which increase the effective bypass ratio (BPR) while reducing fan pressure ratio. When combined with BLI, it increases the overall efficiency, reducing vehicle wake dissipation (Welstead and Felder 2016; Kim et al. 2008).

Full turbo-electric architecture employs all the power from ICE to generate electrical energy. Partial turbo-electric is a variant where the EMs provides part of the propulsive power, the rest is generated by a turbofan mechanically driven by ICE-driven turbofans. This way the electrical components can be sized smaller with corresponding weight reduction (Welstead and Felder 2016; National Academies of Sciences, Engineering and Medicine 2016; IATA 2019). STARC-ABL concept is an example of partial turbo-electric design (Welstead et al. 2017).

Since fans usually operate at lower speed than common EMs, turbo-electric and series hybrid architectures may drive geared turbofan engines that reduce shaft speed, with the benefit of shaft speed decoupling from ICE (Brelje and Martins 2019). An advantage of this architecture is the possibility of using “green fuels” such as Hydrogen. State-of-the-art turbo-electric developments combine SOFCs fueled by hydrogen that supply EMs to drive fans, and cryogenic superconducting components (Ji et al. 2020; Filipenko et al. 2020).

3.5 All-Electric Architecture

All-electric architecture employs batteries as the only source for aircraft propulsion (IATA 2019; National Academies of Sciences, Engineering and Medicine 2016). The advantages are the higher efficiency on energy conversion of EMs and PECs compared with ICEs, and the simpler control strategies required to manage a unique power source. The main disadvantage is the low BED of actual batteries technologies, which makes it not viable for most aircraft.

Another drawback is that, different from aircraft propulsive ICEs that operate outside the fuselage and release heat directly to the atmosphere, electric devices may be located inside the aircraft and heat may be an issue. Actual devices are not designed to work on these conditions, and will be necessary to develop components capable of operating at higher temperatures. Thermal management systems (TMS) for electrical components are necessary and may be included in HEP design, with corresponding additional weight (Rajashekara 2014).

The development of all-electric aircraft is encouraged by the fact that it is a scalable technology, allowing a step-by-step implementation from 1-seat and 2-seat aircraft, toward the 100-seat configurations (IATA 2019). Since 2000, at least 17 manned electric fixed-wing aircraft have been developed, first the Antares 20E, and later the Electraflyer C, Yuneec 430 and Cri-Cri. Over the last years, it was observed an increase on EM’s power density and efficiency, which supports this architecture (Brelje and Martins 2019).

3.6 Distributed Propulsion

One promising concept for integration of aircraft HEPS is the synergy with DP. It replaces the ICE fan on conventional aircraft with several small EM-driven fans embedded into the upper rear surface of the airframe. In conventional ICEs the fan or propeller speed is coupled to the speed of the ICE, while in DP both are decoupled, enabling each device to be operated at their ideal point. This decoupling enables higher BPR with efficiency increasing estimated in 4–8%. Subdividing the thrust, the concept aims for noise reduction, increased efficiency, reducing weight, shorter takeoff and landing distances, reduced fuel consumption and improved stability. Drag reduction, lift augmentation and swirl cancellation are also advantages from DP (Sliwinski et al. 2017; Liu 2013; Brelje and Martins 2019).

Since ICEs generally decrease performance and efficiency when scaled down in size while EMs scale more linearly, the latter is more viable for DP. With small size motors, the installation on wingtip or tailcone is feasible, to cover the wing and body and even benefit from BLI (Brelje and Martins 2019).

A DP configuration with great potential is named Leading Edge Asynchronous Propellers Technology (LEAPTech), with many small propellers distributed span-wise along the wing, which blows the wing on takeoff and landing. This increases the dynamic pressure over the wing, and reduces the wing area with reduction in cruise drag (Stoll and Bevirt 2014).

A DP variation employs two types of propellers: “high-lift” smaller propellers distributed upstream of the wing’s leading edge, and two “cruise” propellers, one at each wing tip. The first ones are operated only at low speeds, and during higher speed, flight props are folded and stowed against the nacelles to reduce drag. The last ones reduce the induced drag on wing tips, and provide all the thrust during higher-speed flight (Patterson et al. 2016). Analysis based on Virtual Disk Model and developed on CFD software show that wing tip distributed propellers reduce the induced drag, and increase the high lift capabilities. Distributed propulsion improves the wing design and aircraft performance (Della Vecchia et al. 2018).

4 Developments in Hybrid-Electric Propulsion

Accounting the components’ individual efficiencies, a conventional propulsion system (ICE and propeller); operates with 20–36% of global efficiency. The same way, an EP system (batteries, PECs, EMs and propeller) global efficiency is 75–83%. EP can be considered about three times more efficient than the ICE propulsion. However, since the highest declared BED of actual batteries (400 Wh/kg) is roughly 30 times lower than the ICE’s jet fuel, the propulsive power relation of ICE with EP is about 10–1. The difference is so high that for all-electric aircraft to be viable on limited range missions (25–50% of conventional aircraft), the BED battery needs to be above 1,000 Wh/kg (Sziroczak et al. 2020).

Since EP is still not commercially viable in the short term, several aircraft manufacturers around the world, such as Boeing, Airbus, EMBRAER and Pipistrel are working on the development of HEP aircraft. Some other companies and institutions, such as Rolls-Royce, Siemens, NASA, TU Delft and DLR are also engaged in these processes through partnerships.

There is not a unique solution for aircraft HEP. Some studies claim that actual technology HEPS in parallel architecture is best suited for aircraft with fluctuating power requirements, this means short duration of high-power requirements (Finger et al. 2020).

HEP offers operational flexibility due to the variety of components and possibilities, but this may imply an increasing in weight. Consequently, it is necessary increasing in thrust during takeoff, which must be considered in the aircraft design phase. HEP increases the complexity in operation and design, but with a management system operating the engines close to their maximum efficiency operation conditions, and with proper energy storage control, environmental requirements and reductions in energy consumption may be achieved (Riboldi 2019).

4.1 Hybrid Concepts and Demonstrators

NASA classifies the aircraft concept with a scale of progressing levels of maturity, the Technology Readiness Level (TRL) (IATA 2019). Some concepts are listed below following this parameter as a reference.

4.1.1 Technology Readiness Level 6–7

A partnership between Airbus, Siemens, and Rolls Royce started in 2017 to manufacture the hybrid E-Fan X, from the aircraft BAe 146, with 50–100 passengers. The airplane propulsion system substituted one of its four ICEs with a 2 MW EM (TRL6–7 (Noland 2020; HECARRUS 2021)). An electrical supply with a distribution voltage of 3000 \(V_{DC}\) was employed. The demonstrator explored the challenges of a high-power HEPS in series architecture, thermal effects, electric thrust management, altitude and dynamic effects on electric systems, and electromagnetic compatibility. The goal is to build a commercial aircraft for 50–100 passengers on regional and short-range routes with 25% of emissions, and EIS by 2035. The demonstrator tests ended on April 2020 (Airbus 2017, 2020; Brelje and Martins 2019; IATA 2019). Figure 6 shows an image of this demonstrator.

E-Fan X (Airbus 2020)

Alice is a 9-passenger all-electric aircraft developed by EVIATION. The power source is a Li-Ion 920 kWh battery pack that contributes with 60% of MTOW. Built in composite material, the design employs two EM driven propellers on wingtips, and a tail EM propeller, with a combined power of 260 kW. BLI architecture reduces drag, increases stability and distributes propulsion. With a cruise altitude of 10,000 m and speed of 123 m/s, declares autonomy of 1,000 km, MTOW of 6,350 kg, and payload of 1,134 kg, with a TRL of 6–7 (HECARRUS 2021). Certification is aimed on 2022 (EVIATION 2020; AIN/McIntosh and Alcock 2020). The Extra 330LE is a single seat, 1,000 kg, all-electric acrobatic plane, powered by a Siemens lightweight EM of 50 kg and 260 kW. It presents a TRL of 6–7 (HECARRUS 2021), with a power density including power converters and TMS of 5.2 kW/kg (Extra Aircraft 2016; Martini and Haller 2017; Brelje and Martins 2019).

4.1.2 Technology Readiness Level 5–6

Another partnership between Pipistrel, Siemens, University of Maribor, University of Pisa, and MBVision, under the European Union program Hypstair, developed the HEP Panthera aircraft. The motor is a series architecture with an adapted Rotax 914 ICE, with maximum power of 100 kW. The Siemens EM has a maximum power of 200 kW, a continuous power of 160 kW, and a power density of 5.2 kW/kg. The aircraft is undergoing ground testing and is scheduled to launch in the next years (Hypstair 2018), with an estimated TRL of 5–6 (Ludowicy , 2019). In Fig. 7, an image of the aircraft is shown.

Demonstrator Hypstair (Hypstair 2018)

e-Genius is a two-seat motor glider series HEP aircraft in series architecture developed by the University of Stuttgart. Powered by a battery pack and a Wankel ICE that drives a generator, with an EM-driven propeller on the tail. The takeoff is supplied by batteries, while the ICE powers on cruise. It is able to fly up to 230 km/h with a declared autonomy of 504 km and cruise altitude of 6,000 m. e-Genius aims to be a test bed for research able to demonstrate technologies up to TRL demonstrate technologies up to TRL 5–6 (Bergmann 2019).

Zunum Aero is a start-up created by Boeing and JetBlue, that aims to develop a passengers 12-passenger HEP aircraft in series architecture. The small airliner with one 500 kW ICE-driven electric generator, powers two EM-driven fans with a cruising speed of 483 km/h, declared range of 1,110 km, takeoff distance of 670 m, and bays on wings for modular battery packs. An EIS is envisaged by 2023, and plans to integrate technologies with a TRL of 5–6 (Knapp et. al 2018; HECARRUS 2021). However, the company is currently in financial difficulties. In Fig. 8, an image of the demonstrator is shown (Zunum 2018; Misra 2018; IATA 2019).

The German Aerospace Center (DLR) developed the HY4, a twin-fuselage, four-seat, 1500 kg aircraft. Each fuselage can seat two occupants. The power source is composed by a PEMFC for cruise flight at an altitude between 470 and 930 m, and a speed of 40 m/s, with lithium batteries for takeoff and climbing extra power. It employs an 80 kW EM and develops a maximum speed of 56 m/s. The airplane is well suited for short flights with low noise and emissions, and is able for takeoff and land on short runways, with a TRL of 5–6 (HECARRUS 2021). The goal is being used as an electric air taxi % and to develop in the future 19-passenger regional hoppers (Lettenmeier 2020; Kallo 2015; Ghosh et al. 2018; Misra 2018).

4.1.3 Technology Readiness Level 4–5

Zunum (Zunum 2018)

Demonstrator Tecnam P2010 H3PS (Tecnam H3PS 2020)

In 2007 Boeing, engineers modified a two-seat Dimona HK36 motor-glider airplane with an electrical drivetrain supplied by a Polymer Electrolyte Membrane FC (PEMFC) and Li-ion batteries, with a maximum takeoff weight (MTOW) of 770 kg without payload, and a maximum L/D ratio of 27. The original ICE was replaced by the HEPS in series architecture, to feed a DC voltage 30 kW EM that drives a variable pitch propeller. The thermal energy comes from a FC, the main power source for level flight at 1,000 m consuming 17.5 kW at 27.7 m/s, while batteries supply extra power of 27.5 kW for takeoff and climb. FC technology level is estimated TRL 4–5 (IATA 2019; HECARRUS 2021). The overall weight increased was of 150 kg, from this 12% is from the FC and 10% from the batteries (Lapeña-Rey et al. 2007; Koehler 2008; Misra 2018).

Demonstrator HK36 (Koehler 2008)

Demonstrator HY4 (Lettenmeier 2020)

Demonstrator eGenius (Stuttgart University 2020)

Demonstrator Ipanema (WEG 2019)

Demonstrator Alice (AIN/McIntosh and Alcock 2020)

Demonstrator Extra 330LE (Extra Aircraft 2016)

The Parallel Electric-Gas Architecture with Synergistic Utilization Scheme (PEGASUS) is a 48-passenger regional aircraft concept based on the ATR 42-500, and holds a TRL of 4–5 (HECARRUS 2021). It combines two parallel HEPS on the wingtips, with EP inboard and at the aft of the vehicle (Capristan and Blaesser 2019; Brelje and Martins 2019). NASA is investing in research on airplane concepts, electrical power systems, component materials, and test facilities. The X-57 Maxwell is a small experimental all-electric architecture airplane, converted from the Tecnam 2006T, with electric motors in DP powered by a lithium-ion battery pack. It aims to reduce noise, fuel consumption and emissions, with a TRL of 4–5 (HECARRUS 2021) (NASA 2020; Misra 2018; Brelje and Martins 2019).

4.1.4 Technology Readiness Level 3–4

ECO\(^4\) is a four-seat airplane developed by the University of Stuttgart, with a cruise speed of 222 km/h, declared fuel consumption of 40% less than conventional airplanes, declared range of 2200 km, with a TRL of 3–4 (Stuttgart University 2020; HECARRUS 2021).

NASA is also testing gas turbine generator interactions with BLI. In Fig. 16 is the largest HEP aircraft seriously studied called N3-X. A hybrid wing body (HWB) concept twin aisle passenger was designed, and wing-mounted liquid hydrogen-fueled turbo-generators with 30 MW in a full turbo-electric HEP architecture. 14 EM-driven propellers on a DP concept are located on the trailing edge, a BLI configuration. These distributed propellants help to reduce fuel burn by efficiently producing thrust while re-energizing the aft boundary layer. System safety analysis of high-power propulsion, and superconducting with associated cryogenic subsystems have being considered, claiming a 70% fuel burn reduction compared with the Boeing 777-200, with a TRL of 3–4 (HECARRUS 2021). It is envisioned to EIS in the 2040s (NASA 2019; Brelje and Martins 2019; Kim et al. 2008).

Concept N3-X (NASA 2019)

With the base of concept N+3 conventional configuration (N3CC) NASA developed the Single-aisle Turbo-electric AiRCraft with Aft Boundary Layer (STARC-ABL). It is a 150-passenger, single-aisle tube-and-wing concept. Two underwing geared turbofan engines with attached generators to fan, generate electrical power sent to a rear fuselage, EM-driven fan in BLI. The influence of TMS was not analyzed. Turbofans contribute 80% thrust on takeoff and 55% on top of the climb. The partial turbo-electric architecture has the advantage that electrical machines independently vary the torque and speed, increasing efficiency and operability in off-design conditions. With similar weight in both designs, a fuel burn reduction of up to 12% and emissions reduction of 10% compared with the base concept were related, because of the efficiency increase from rear fuselage BLI, and due to the downsizing of the turbofans, with a TRL of 3–4 (HECARRUS 2021). EIS is envisaged between 2035 and 2040 (Welstead and Felder 2016; Welstead et al. 2017; Yoon et al. 2019; Brelje and Martins 2019; IATA 2019). A research was full and partial turbo-electric hybrid architectures were compared for a N3-X aircraft, concluded that partial design is the best unless radical advances in superconducting and cooling techniques are developed (Liu 2013).

Concept STARC-ABL (NASA 2019)

Since 2006, Boeing, in partnership with NASA, is working on Subsonic Ultra Green Aircraft Research (SUGAR) program to achieve the N+3 goals. Ideas such as alternative fuels, electric aircraft, improved aerodynamics and propulsion, and sustainable materials are being analyzed on a 900 nmi and 154 seats aircraft. Concepts called High, Volt and Freeze are being tested on simulation or laboratory. SUGAR Volt uses two hybrid turbofans on takeoff, and EMs while flying, with long, braced, high aspect ratio wings to decrease drag. It is the only concept able to meet the N+3 goal of 70% reduction on emissions, with a TRL of 3–4 (HECARRUS 2021). On 2019, wing design tests declared a reduction of 8–10% on fuel burn (Droney 2017; Brelje and Martins 2019; Boeing 2019).

Concept SUGAR Volt (NASA 2019)

The Wright 1 is a 186-passenger all-electric aircraft concept developed in partnership with the airline EasyJet, with a TRL of 3–4 (HECARRUS 2021), and projected to fly on 2035 (Wright Electric 2020; Misra 2018; IATA 2019).The Bauhaus Luftfahrt concept Ce-Liner is a 189-passenger and 1670 km autonomy aircraft, with C-wing configuration, and envisaged EIS by 2035 (IATA 2019), also with a TRL of 3–4 (HECARRUS 2021).

4.1.5 Technology Readiness Level 2–3

A 150-passenger regional aircraft is the ECO-150, a turbo-electric DP concept developed by Empirical Systems Aero-space (ESAero) and Wright Electric (E/S/Aero 2020; Brelje and Martins 2019), with a TRL of 2–3 (HECARRUS 2021). Other demonstrators and concepts have been developed over the last few years. A small aircraft based on the EMB-203 Ipanema with 100% EP is currently under development by EMBRAER. The EM and controller are being manufactured by the partner company WEG, and Parker Aerospace will supply the cooling system. The aim is to evaluate vibrations, shocking, electromagnetic interference, performance, etc. of the electrical drivetrain. Actual stage is on test bench, and the first flight is scheduled for 2021 (WEG 2019). On 2014 the SORA-e demonstrator, a Brazilian 2-seat all-electric aircraft developed by ACS Aviation in partnership with ITAIPU Binacional was tested (ACS Aviation 2019). The CENIC C-1 is an all-composite EM glider aircraft, also from a Brazilian manufacturer (Barufaldi et al. 2020).

A partnership of Rolls-Royce and Tecnam is developing the H3PS, a modified 4- passenger aircraft model P2010. A HEP in parallel architecture was installed with a Rotax 104 kW 4-cylinder ICE, and a 30 kW EM. The propeller is powered most of the time by the ICE, and the EM adds extra torque when needed. The EM serves as a starter-motor for the ICE, a thrust booster in the climb, and shifts to generator in cruise for battery recharge. The ICE size was reduced and provides maximum power most of the time, increasing the efficiency. With downsizing of ICE, the battery extra weight is less significant. Previously these partners developed the eFlyer 2, with series architecture (Tecnam H3PS 2020).

A hybrid-electric VTOL aircraft powertrain concept called Integrated Distributed Electric Propulsion, is being developed by VerdeGo Aero in partnership with Continental. It is a 3,400 kg aircraft that employs a Jet-A fueled piston ICE, a hybrid-electric system in series architecture, and several EM-driven propellers in DP (Continental 2019; EEPower 2020).

Concept VerdeGo (EEPower 2020)

Pipistrel has developed several all-electric demonstrators. Alpha Electro is a 2-seat trainer airplane (Pipistrel 2020a). In 2007 it was released the Taurus Electro, a two-seat self-launching glider (Pipistrel 2020b). Puma 3 AE is an electrically powered fixed wing easier to hand-launch aerial vehicle developed by AeroVironment. It has been tested using a FC to supply the electrical system (AeroVironment 2020; Sliwinski et al. 2017). Antares DLR-H2 is a mono-glider in HEP series architecture that uses hydrogen-fueled FC as power source (Ballard 2008). The SR20h is a modified Cirrus SR20 equipped with HEP in parallel architecture (Wall and Meyer 2020).

The NASA Scalable Convergent Electric Propulsion Technology and Operations (SCEPTOR) is a flight demonstrator project that retrofit the ICE powered Tecnam P2006T aircraft, removing the wing and replacing it with an experimental wing integrated with EMs (Borer et al. 2016; Patterson et al. 2016).

A version from the company Bauhaus Luftfahrt is the “Claire Liner”, a box-wing with propulsive fuselage and full annular BLI, with turbo-electric architecture (Frediani et al. , 2012).

Some other developments are the turbo-electric aircraft Ampaire Tailwind with BLI, and the HEP VTOL aircraft XTI TriFan 600 propelled by three ducted fans (Brelje and Martins 2019; Brown et al. 2019; Olcott 2016).

5 Developments in Aircraft Design and Systems Integration

Aircraft design will be the critical synergy to support the technological advances on HEP. The first step on aircraft design is the conceptual phase, in which the major elements and properties of the aircraft are defined. The aircraft design starts with the requirements and specifications, and later the definition of constraints derived from airworthiness, aerodynamics, safety, etc. Propulsion system specification on HEP must evaluate the engines, ignition system, fuel supply, cooling control, exhaust management, etc. (González Espasandín et al. 2014). The second step is the conceptual design, determining shape, size, weight and performance, and applying optimization methods. The conceptual design is based on aerodynamic, propulsion and structural solutions, and utilizes user-friendly software such as Advanced Aircraft Analysis (AAA) by DAR, RDSWin, Simulating Aircraft Stability and Control Characteristics (SimSAC), and Stanford University Aerospace Vehicle Environment (SUAVE), this last developed in collaboration with EMBRAER (Sziroczak et al. 2020). Aircraft design optimization requires integrated modeling and simulation capabilities. Software tools such as ESAero’s, PANTHER, GT-HEAT, LEAPS, and OpenMDAO are also employed in demonstrators and concepts development (Brelje and Martins 2019).

Using this classification the prevision until 2035 is that aircraft design will work on evolutionary tube-and-wing configurations combined with HEP, with turbofan engines powered by jet fuel or equivalent, improving fuel efficiency up to 30% compared to 2005. Advances on ICE’s design, electric taxiing systems (Lukic et al. 2018), PECs, and FCs auxiliary power units (Daggett et al. 2003) aim to reduce fuel consumption.

From 2035 onward, it is expected revolutionary aircraft configurations, to achieve the long-term climate goal (reducing \(\hbox {CO}_2\) emissions by 50% in 2050 compared to 2005). However, economic and commercial constraints may delay or even prevent their implementation (IATA 2019).

Novel aircraft configurations such as hybrid wing body (HWB) (Kim et al. 2008), blended wing body (BWB) (Yang et al. 2018b; Boeing 2017; IATA 2019), strut-braced wings (SBW) (Harrison et al. 2020; Bradley and Droney 2012), Fixed Wing (FW) (Van Oppen et al. 2020) Transonic Truss-Braced Wing (TTBW) (Boeing 2019), and Box-Wing Tasca (2021); Palaia (2021) are more environmentally friendly and quieter than conventional designs.

Box-Wing employs Prandtl plane architecture to achieve higher payload and passengers capacity, with lower fuel per pax-kilometer and lower emissions, compared with conventional designs. A CFD model of a medium range aircraft was developed, and results claim an estimated fuel consumption reduction of 22% (Tasca 2021). Conceptual tools are employed for unconventional design such as the box-wing. A regional aircraft model was developed with one of this tools, and results concluded a significant decrease in fuel consumption, but actual low values of BED reduce the design space (Palaia 2021). Other configuration, such as double-bubble fuselage and box/joined-wing, combine BLI with new designs for fuselage or wings to reduce drag and improve efficiency. The compactness of EMs enables to be used on wingtip propellers, that aim to cancel some swirl in the vortexes, with estimated drag reduction between 5% and 10% (Brelje and Martins 2019).

Considerable weight reduction is being achieved with composite materials and light metal alloys. NASA is testing shape memory alloy (SMA) and morphing wings, for aircraft wings able to modify its shape and obtaining a better lift (Young et al. 2019; IATA 2019).

Studies indicate that HEPS is a viable solution in small-to-medium size aircraft, and synergy with DP is one of the most promising concepts. A design trend on hybrid-electric architectures is to employ the EMs to deliver the additional thrust during takeoff, while the ICE could be reduced in size (Sliwinski et al. 2017). Software tools as “FAST-CS25” are employed to evaluate the feasibility of DP architectures (Ruscio et al. 2021). The effect of HEP with DP on aircraft performance is studied with the help of a weight estimation method called Class-II, to size the aircraft including aero-propulsive interaction, and to estimate the energy consumption (Hoogreef et al. 2019). Other sizing method for conceptual design involves the powertrain architecture, and calculates the wing area, powerplant size, and takeoff weight. This work states that DP increases wing loading and improves the lift-to-drag ratio (de Vries et al. 2019).

On parallel architecture ICE could keep operating on its nominal power, obtaining additional power from EM of takeoff or climb stages, and using excess ICE power to charge the batteries on cruise stage (Wall and Meyer 2020).

Critical design aspects are: constrains on mass fraction, constraints for energy fractions of flight mission legs, hybridization factor, radically new elements and technologies, and developing unconventional aircraft. Maximum takeoff mass is the most often used objective function in aircraft design process. Constraints are derived from airworthiness, aerodynamics, safety, structural integrity, etc., and are also critical. The requirements analysis considers determining the shape, size, weight and performance of the planned aircraft, and applying optimization methods, considering the constraints. Under this frame the battery sizing is performed considering the low BED (Sziroczak et al. 2020). The design space for propulsion requires evaluation of safety and regulatory compliance. Varying values of BED need to be explored for optimization of electric aircraft. EP eliminates fuel risks but introduces new ones. Constraints of electrical devices thermal management systems are coupled with the rest of aircraft design problem. Multidisciplinary optimization of electrical, propulsion, thermal management and aerodynamics must be developed (Brelje and Martins 2019).

6 Developments in Aircraft Electrical Systems

The major drivers for aircraft electrification are the reduction of emissions and operating costs, and increase in efficiency (Misra 2018). From this, specific power of EMs and PECs is a key parameter in the design problem (Brelje and Martins 2019).

EMs are usually specified from the short-term burst power, higher than the maximum continuous power. High electrical components efficiencies near 100% are within reach nowadays (Brelje and Martins 2019).

The operation of an aircraft 100% supplied with electrical energy is a great challenge, since loads in the vehicle have different priorities along the flight phases. This may affect the voltage levels and stability, and make the electrical distribution to suffer radical variations (Buticchi et al. 2017)

6.1 Developments in Power Electronics

PECs are essential components to combine the different power sources and drives on a HEP architecture. Dedicated controllers may apply intelligent and rule-based strategies to integrate components and achieve maximum global efficiency (Sliwinski et al. 2017). New PEC concepts and challenges are being tested to optimize HEPS, and some of them will be briefly described.

Starting current in converters can cause a lot of damage to electronic equipment in the long run. For this, there are several types of PECs to correct the power factor on buck-boost operation. Control algorithms are used to minimize the EM’s starting current and achieve a power factor close to one. Two PEC rectifier controls are presented in a work, a nonlinear for voltage and a type 2 for current, aiming to minimize the starting time to a minimum. The start-up time is significantly reduced (Mallik and Khaligh 2017).

An advantage of using electric systems on aircraft is that highly dynamic PECs and EMs may instantly develop torque over a wide range of speeds, increasing security when required to perform a go-around procedure on the mission. Also, these equipment work independently of the air pressure (Henke et al. 2018).

Direct current (DC) distribution is favorable for electric power distribution, since it eliminates the need to synchronize multiple electrical generators and EMs and simplifies “throttling” for DP applications, but adds weight due to AC/DC converters (Brelje and Martins 2019).

In the MEA framework an efficient and versatile electrical distribution is required. Quad-Active-Bridge (QAB) topology in conjunction with variable virtual resistor control manage different load priorities in the MEA distribution system, extracting power from multiple buses on peak demand, reducing the need to over-designing the EMs. The QAB converter can be used as a storage manager ensuring galvanic isolation between ports, and prioritizing power consumption from fast power sources. The main challenge is to control the energy flow between different sources. Simulations show that in small rapid variations, the feedforward control strategy is sufficient to guarantee good performance. Experiments in a high voltage (HV) scenario show that the converter can achieve very good efficiency with the use of Silicon Carbide (SiC) devices. The QAB can effectively replace three single input/output power converters for storage integration (Buticchi et al. 2017).

The key elements of a DC/DC converter on MEA are galvanic isolation and fully controllable power. To increase efficiency, the topologies of Packed E-Cell must be of the resonant type. Converters can be of the types Series Resonant Converter, or Dual Active Bridge. The first one presents problems in the regulation of voltage and current, while the second improve power control with high performance. The Dual Active Bridge converter with SiC present good results. High switching frequencies increased the PEC’s power density, but cause high variations in voltage and current, increase electromagnetic interference, and capacitive effects and deterioration of the transformer (Buticchi et al. 2017).

In Alberto et al. (2019), an algorithm for adaptive control is presented for a PEC that transfers the power between a HV bus, and a DC electric generator, and a battery bank that operate on the low voltage side. The interface between these two voltage sides is by a buck-boost converter PEC. The algorithm charges of the operation of the isolated gate bipolar transistors (IGBT) gates, keeps the generator current operating at a defined value, and maintains the state of charge (SOC) of the batteries, preventing it from discharging completely. A sliding order mode control strategy is said to be the next approach aiming to reach the highest optimal condition.

To increase the HEPS reliability it is highly recommended to use modular PECs, which present high efficiency and a high power handling. They satisfy the redundancy requirements, but energy management leads the equipment to high temperatures and is prone to failure. A structure was designed with a routing algorithm, in order to optimize energy management between the HV and low voltage bars, which increases the useful life of the entire system. The sensitivity to the variation of the thermal parameters is studied with a Monte-Carlo analysis (Raveendran et al. 2019).

A configuration with three PEC inverters powered by individual PEC rectifiers is proposed for an all-electrical aircraft. With this configuration, control can be done individually for each of the phases, whereby, for nonlinear loads, harmonic distortion can be compensated more effectively. Integration voltage regulators are used for the first to the ninth odd harmonics. The control was simulated using the programming language C (Anuchin et al. 2015).

A work describes a HEPS on series architecture with FC and three battery packs. It proposes to connect the battery voltage of each pack in series with each AC phase of the EM, generating a short power boost during high power demand. This way it eliminates the DC/DC converter. However, the switching of the batteries requires a complex circuit for a careful synchronizing (Ghosh et al. 2018).

In some electric aircraft topologies power sources, such as AC generators and FCs, provide the base power, while batteries and supercapacitors supply short-term peak power on load transients. All of them are commanded by the electric power distributed system (EPDS). Batteries, supercapacitors and FCs are DC energy sources that level at low voltage, and require converters to integrate with the DC bus. High-conversion high-voltage (HCHV) DC-DC converters with higher DC bus voltages are a trend in electric aircraft development, aiming to reduce size and weight and to increase power density. However, electromagnetic interference, safety and reliability are a primary concern. Two-port converters and multiport converters architectures are analyzed for HCHV. The first one endures reliability, while the second, that improves the power density. Multiport converters architecture would be the best option for aircraft because of the power density, despite of lower reliability (Swaminathan and Cao 2020).

Power density and efficiency are two of the major metrics to evaluate PEC in aircraft HEPS, since electric devices are required to be more power dense. To reduce losses and weight in conductors, DC distribution in the kilo-Volts range is a demand for aircraft EP. Conventional PEC for applications in the megawatt (MW) power range operates on low switching frequency, and does not meet the requirements of high frequency, medium voltage and MW power level for aircraft BLI applications. A 1 MW three-phase three-level inverter with DC bus voltage of 2,400 V and fundamental output frequency of 1,400 Hz, is proposed to meet the requirements for aircraft HEP applications. The inverter utilizes SiC metal oxide semiconductor field effect transistors and silicon IGBTs, with active neutral point clamped (ANPC) (Pan et al. 2020).

Poly-phase drivers have advantages such as reduction in EM torque pulsation, increasing in frequency, reduction in power per leg of inverter, reduced volume, lower DC link current harmonics and reduced rotor copper losses (Gupta et al. 2020).

PECs based on SiC switches show a significant size reduction compared with silicon devices, and further reduce the cooling requirements (Rajashekara 2014).

An electrical extension of the HEPS model is proposed in (Bongermino et al. 2017), that includes the EM and a DC/AC converter. It is a high-speed EM with synchronous resistance assisted by a Permanent Magnet-Assisted Synchronous \(\cdot \) Reluctance Motor, in which the model is reduced to the stator’s equations. The permanent magnets cause a reduction in the flow in the square component term, and an increase in the torque. In the model, the inverter is used to drive the EM in a function block with a code written in C. This model considers the behavior in the line of IGBT transistors.

Some works on PECs applied to aircraft HEP are being developed to compose a test bench that aims to study the performance of several hybrid architectures. In Nascimento et al. (2019) a back-to-back PEC connects a permanent magnet synchronous generator driven by a gas turbine, with a DC bus and EM-driven propeller. Power and control simulation is performed, and performance is analyzed. In Torres et al. (2019); Bastos et al. (2020), an interleaved bidirectional DC-DC converter that regulates the battery pack of the cited test bench is modeled with a small-signal state space approach, and simulation results are presented. In Gomes et al. (2020), a dynamic model for a PEC inverter that drives a permanent magnet EM, through an integral–proportional (IP) control law for current and speed, is simulated and analyzed. In Nascimento et al. (2020), resonant controllers applied to a three-phase PEC rectifier of a high frequency electric generator are analyzed.

6.2 Developments in Electrical Machines

EMs convert electricity into kinetic energy which in turn is fed to a propeller, fan, or rotor, with reduced mechanical noise and thermal signature. Electricity is required not only for the aircraft propulsion but for communications, and recent advances in weight saving of EMs have allowed HEP to be more competitive (González Espasandín et al. 2014). EMs with high power-to-weight ratios (PWR) are required for HEP applications (Corduan et al. 2020).

Several parameters may be optimized in EM design. Rectangular wire winding results in smaller machines. Increasing the number of phases strengths the fundamental wave, resulting in higher torque and efficiency, while higher-order harmonics are significantly reduced (Henke et al. 2018). Employing a multi-phase EM, the machine can continue to provide power even with a fault in one of the phases. EM switched reluctance is fault tolerant, stable to operate at high speeds and in harsh environments, with relatively high power density. It is a prime candidate for embedded generation in aircraft applications (Rajashekara 2014). Design of EMs may be based on material characteristics. The mass of soft-magnetic parts can be reduced by higher saturation, and high current density materials, such as aluminum instead of copper, can reduce the weight of winding (Henke et al. 2018).

Electric motors (EM) on operation do not produce emissions which makes them a critical technology for reaching the aircraft environmental goals for 2050. Also, EMs are well suited for DP architectures, since they require much less maintenance than ICEs. A larger number of separate EMs on an aircraft does not lead to higher maintenance costs (IATA 2019).

One of the main concerns in the design of EM for aircraft propulsion is the overall efficiency. A fraction of the input energy is lost in the circuit resistance, another in the commutation inside the PEC, an another in the dispersion of the magnetic flux. Some energy is lost in the ferromagnetic material, and some in the friction of the moving parts.

NASA expects EMs in the 1 MW power class to achieve a power density of 13–16 kW/kg and efficiency of 96–99% by the N+3 time frame (Brelje and Martins 2019).

Superconducting materials (SM) are being tested for aircraft electric components, aiming for weight reduction. SM has a significant decrease on electrical resistance bellow a “critical” temperature (usually between 20 and 65 K), and is able to can carry high current values in conductors with reduced dimensions (Malkin 2013). EMs with high temperature superconducting (HTS) materials such as bismuth strontium calcium copper oxide (BSCCO) (critical temperature 110 K) have already been designed. HTS materials, would be used on HEP aircraft with ICEs fueled by liquid hydrogen. The fuel could cool the electrical components before being burned (Masson et al. 2007).

Two types of superconducting machines (SCM) are being studied, full SCM with superconducting materials at armature winding and rotor field coils, and conventional SCM with superconducting field coils and conventional copper armature winding. Full SCM has the potential of achieving higher power density. If magnesium diboride \(\hbox {MgBe}_2\) wires are employed, the required diameter is about 25% of current copper wires (Terao et al. 2018).

Even using HTS cooling is a challenge. Rare earth barium and copper oxides (YBCO) are the most commonly used, with threshold temperatures up to 125 K. Cooling fluids include liquid hydrogen or liquid neon, and incorporate them into an aircraft is difficult, but the size of the machine would be reduced by 70%, reaching power-to-weight ratios up to 8 kW/kg, and torque densities up to 2 Nm/kg (Henke et al. 2018).

Actual EM has a PWR up to 5.2 kW/kg (Terao et al. 2018). For concepts such as the N3-X, EMs with a PWR of at least 12.7 kW/kg are required. Varying parameters such as the number of pole pairs p, rotor and stator dimensions, and coils characteristics, designs of fully (rotor and stator) and partial (only in the rotor) SCM may be calculated looking for the highest PWR (Corduan et al. 2020).

6.2.1 Permanent Magnet Motors

Permanent magnet synchronous motors (PMSM) and cage induction motors (IM) are some concepts that may achieve high torque density or high power density. EMs with high-speed operation design have the advantage of lower volume for the same power output. PMSMs are widely used on railway traction, ship propulsion, generators, etc. Since they do not have field winding perform higher efficiency, higher power density and lower heat in the rotor, they are the most feasible to be used on aircraft (Henke et al. 2018).

High specific power density EM is a key technology for HEP, and high fundamental frequency combined with genetic algorithms is an approach for air core machines design (Zhang et al. 2016). A motor with slotless topology that retains high specific power at low rotation may be designed. Low rotation is a condition employed in BLI propulsors (Yoon et al. 2019).

Rare earth magnets such as NdFeB and SmCo with high energy densities are especially used for the rotor, but are rather expensive. For aircraft applications, the weight, iron losses and mechanical stability are critical. Cobalt-iron CoFe alloys provide the necessary magnetic flux in rotor with lower material. Phosphorus-copper CuP, Beryllium Be or some aluminum Al alloys may be used for high-speed and high power density rotors (Henke et al. 2018).

6.3 Developments in Energy Storage Technologies

Energy storage is one of the fundamental technologies to support HEP for larger aircraft. The main energy storage technologies for aircraft are the batteries, but FCs and supercapacitors are also being tested. Harvesting systems such as solar photovoltaic cells can be added to any of the cited storage technologies.

Nowadays batteries are the most used electrical energy storage device. Current technologies are: alkaline, lead-acid, nickel–cadmium (Ni–Cd), nickel metal hydride (Ni-MH), lithium-ion (Li-ion) and lithium-ion polymer (Li-pol), the latter two are the most available (Gao et al. 2015). Innovative technologies include lithium-air, lithium-sulfate (Li-S), zinc-air, aluminum-air, magnesium ions and graphene (Sliwinski et al. 2017). Despite the evolution in the last years, batteries still need to increase the BED to make purely electric flight more feasible. This parameter for aviation fossil fuels is about 12000 Wh/kg, while for Li-pol is about 250 Wh/kg (González Espasandín et al. 2014). In the case of a regional hybrid-electric aircraft, 500 Wh/kg would be needed to achieve around 50% hybridization factor.

The biggest challenge for batteries supply aircraft EP is that it has around 50 times lower specific energy than liquid fuels. Since batteries do not lose mass during flight compared to jet fuel, they still carry a “hidden” weight that induces a drag penalty (Brelje and Martins 2019).

Energy density in Wh/kg and specific power in kW/kg are important constraints on the design problem. In some stages of flight such as takeoff of a HEP aircraft, it is required more power from batteries. This would be a critical design parameter since batteries have relatively high specific energies but moderate specific power (Brelje and Martins 2019).

Li-ion batteries are the current commercial for automotive applications with specific energy in the order of 250 Wh/kg. There are claims that achieving values up to 400 Wh/kg is possible with silicon or silicon-carbon anodes. Cathode alternatives include high-Ni NMC and sulfur. Some optimistic projections claim that cells with 400–500 Wh/kg could be available in the 2022–2025 time frame. Since high power batteries are required at the beginning and end of the flight, the cycle life is expected to be lower than for the automotive sector. High specific energy batteries would have a lower cycle life (Misra 2018).

Lithium-air batteries have theoretical high BED in the order of five to ten times of Li-ion. It has an anode of Lithium and an “air” cathode made of a porous material that draws in oxygen (Rajashekara 2014).

Li-S battery is a promising technology for aircraft use, with a theoretical specific energy of 2600 Wh/kg, suitable to operate at very low temperatures, and to be installed in thin-film layers along the wing distributing the weight and reduced cost of sulfur (Gao et al. 2015; Sliwinski et al. 2017). The low BED (Wh/L) and short life cycle of Li-S batteries were improved with a new lithium-metal technology (Sion Power 2020; Placke et al. 2017). Actual commercial Li-S batteries declare specific energy up to 500 Wh/kg. A full-scale production plant is under construction in Juiz de Fora, Brazil (OXIS Energy 2020).

FCs convert chemical energy from fuels directly into electric energy by combining hydrogen in the fuel with oxygen, with higher efficiency and less pollution than ICEs. According to the DLR, HEP powered with FCs in substitution to ICEs is a promising approach, and are being studied to supply aircraft HEPS (Amelang 2018).

FCs hold a higher energy density, but its concentrated mass introduces a complexity into the aircraft design dynamics. They offer modularity, fuel flexibility, low noise, and do not generate greenhouse gas emissions but water and heat that can even be used for requirements in large aircraft. FCs do not need to be recharged while fuel and oxidizer are supplied, and are well suited for unmanned aerial vehicles that do not have life support systems for crew and passengers. Regenerative FCs may achieve energy densities above 400 Wh/kg. Combining FCs with PECs, EMs and propellers is the typical architecture for FC powered UAVEs. However, the high weight, low power density, high cost, and lack of hydrogen availability are some disadvantages (Brelje and Martins 2019; González Espasandín et al. 2014; Gao et al. 2015; Misra 2018).

PEMFC fueled by hydrogen have a lower weight than solid oxide FCs (SOFC), and work in low temperature, high current densities, quick start-up, high energy density (600–800 Wh/kg) and low power density (0.5–1 kW/kg). The use of hydrogen as a fuel may have disadvantages as high generation cost, extra weight needed for compressed/liquefied storage, low energy per volume, and risk of explosion. Hydrogen has a high heating value and reaction products in the FC are water and heat, but auxiliary systems may be needed for thermal control or water management. Its low power density limits its application to small airplanes. For being a viable option for a Boeing 737-class airplane, the power density must be around 8–10 kW/kg. Advanced technologies for increasing the PEMFC power density such as lightweight bipolar plate, low catalyst loading, thinner membrane, and lightweight TMS are being studied (González Espasandín et al. 2014; Sliwinski et al. 2017; Misra 2018).

SOFC uses a solid ceramic oxide electrolyte for ion transport and operates at higher temperatures (\(600^{\circ }\)–\(900^{\circ }\)), it uses hydrogen as a fuel with an efficiency of 60%. Its low power density of \(<500\) W/kg limits its application to small electrified aircraft (Misra 2018).

The use of methanol as a fuel for FCs has advantages in storage, energy density and cost. Direct Methanol FCs (DMFC) have less power density but higher energy density. Regenerative FC (RFC) is a new concept where the stack operates as an electrolyzer or as a FC (González Espasandín et al. 2014).

A growing trend is observed in the use of FC in these UAVEs. Using FCs in a small-size UAVEs is feasible, but there are several types of FCs and particular characteristics define the most appropriate application. Due to its low power density and efficiencies, near 50%, hybridization of FCs with electric batteries is necessary in most cases, where FC is used as the primary power source, and batteries for boost supplying during high power demand. High temperature FCs are not appropriate for UAVEs due to its large size, weight and start time, and the auxiliary system required for thermal management (González Espasandín et al. 2014; Ghosh et al. 2018).

Supercapacitors are receiving attention because of their high efficiency, rapid charge and discharge capability (power density around 10 kW/kg), simple support circuitry, long cycle life (> 15 years) and safety. The drawback is their low energy density (< 10 Wh/kg). Research is under way on hybrid battery-supercapacitor, to increase this parameter to 30–40 Wh/kg, keeping power density on 3–5 kW/kg, with 80% of efficiency (Misra 2018).

Solar powered aircraft employs photovoltaic cells covered on the wing to extract energy from the sun, and rechargeable batteries on the fuselage. They can be employed in unmanned HALE missions, charged in daytime and discharged in nighttime. Also in forest fire fighting, ground tracking, precision agriculture, and even in Venus and Mars exploration. However, structural material, aerodynamic efficiency, control and power supply systems need further refinement to achieve reliability in aircraft. Just a few photovoltaic cell types can be applied on aircraft due to efficiency, weight, cost, environmental adaptability and reliability. Silicon type is the most used with efficiency of up to 22%. The problem is the application of the brittle crystalline materials along the smooth aerodynamic contour of airfoil. Thin-film cell types especially of gallium arsenide (GaAs) are being tested with a theoretical efficiency of up to 44%. However, it is three times heavier than silicon, with less cost-effectiveness. Silicon photovoltaic cells are the main solar-cell available nowadays, despite higher energy efficiency of GaAs, because of the weight and cost-effectiveness (Gao et al. 2015).

6.4 Considerations of Using Electric Devices on Aircraft

Replacing ICEs and jet fuel with EMs and batteries is supposed to reduce the maintenance cost in an all-electric aircraft, but this is not supported yet by a quantitative study. Electricity is cheaper than jet fuel on a per-unit-energy basis, which may result in operating cost savings. However, electric power generation is not actually emissions-free, since it requires considering generator fuels, transmission/grid losses, and life-cycle analysis of battery production and disposal. Today’s electric power generation in world average produces roughly 0.6 kg \(\hbox {CO}_2/\)kWh. A reduction of 80% in CO2 emissions is expected after 2040, thanks to a strong trend toward renewable energies (Brelje and Martins 2019; IATA 2019). As the development of batteries with enough BED will take about 15 years, HEP aircraft will EIS before to attain the environmental goals and market demands.

In contrast to ICEs, electric devices, such as EMs, PECs and FCs, are located within the aircraft and do not dissipate heat through exhaust gases. For this reason, a TMS with liquid cooling radiators is required (Lapeña-Rey et al. 2007). This additional equipment is estimated to contribute with around 6% of weight of corresponding PECs. Safety issues related to thermal runaway of batteries, vibrations, shocking, and HV of aircraft electrical systems are also aspects that will demand attention. Corona effect in HV electrical components will require to take care of degradation on isolation materials, and optimization in size and weight of components (Brelje and Martins 2019). Another aspect to be considered is the need for high-power electricity supply infrastructure for recharging electric aircraft in the airports (IATA 2019).

Electrical propulsion will succeed if new technologies attain the required specific power, weight, and reliability (National Academies of Sciences, Engineering and Medicine 2016). Conventional electric devices developed for the automotive area should migrate to aviation, but these equipment are still too heavy to be used on aircraft. Insufficient BED, and the necessary addition of other electrical components, such as generators, PECs and EMs, impose severe weight and volume penalties (Sliwinski et al. 2017).

The use of superconducting materials for EMs is seriously considered for aircraft propulsion systems. Conceptual studies favor superconducting architectures for very high power applications. The NASA NX-3 concept proposes to reach the low temperatures with a reverse Brayton cycle cryocooler. However, this technology requires overcoming several technical challenges and is not expected to be ready for an aircraft within the next 30 years (Brelje and Martins 2019).

Some key improvements are necessary for the viability of small-size electric and HEP aircraft: Communications technology, GPS accuracy, smaller sensors and microprocessors, energy storage optimization and artificial intelligence (AI) applied in autonomy of flight (Goyal 2018).

Most of the times, the primary HEP power source is an ICE, supported by electric sources such as batteries, FCs or solar panels. Different from batteries, liquid fossil fuels have high energy density, and may be stored in complex geometries such as aircraft wings. The solid characteristic of batteries must be considered in the design stage (González Espasandín et al. 2014; Sliwinski et al. 2017).

Some challenges faced by batteries include thermal instability, limited life (charge–discharge cycles), and long charging time (Sziroczak et al. 2020). Battery-powered all-electric aircraft will need more time until EIS than HEP. Studies indicate that hybrid technology will be possible for low power aviation when BED attain above 400 Wh/kg, and will not be practical for regional aircraft until it achieves more than 800 Wh/Kg (National Academies of Sciences, Engineering and Medicine 2016). Other previsions state that it will need more than 500 Wh/kg to make viable all-electric UAVE, competitive with today’s systems. These values are not expected before 2030 (Henke et al. 2018; Brelje and Martins 2019; Berger 2020). Besides, low temperatures at cruise altitudes will affect the battery capacity of future aircraft (Welstead et al. 2017).

Since the most viable FC technologies use hydrogen, they will require a regular supply of fuel for a long scale use in the aircraft industry. Their implementation for on-board power supply in the next decades is likely, once a worldwide hydrogen supply structure is being promoted as a clean energy source for various industry sectors (IATA 2019; IEA 2019).

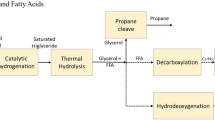

7 Developments in Aircraft Internal Combustion Engines

Aircraft thermal propulsion can be classified by the type of heat source (ICE or FC). ICE is the most usual method, classified in jet or reciprocating engines. Jet engines are classified in turbojet (for combat aircraft), turbofan (for large commercial aircraft), or turbo-prop (for medium aircraft) (González Espasandín et al. 2014). Reciprocating engines are heat engines that uses one or more reciprocating pistons to convert pressure into a rotating motion.

The most efficient aircraft ICEs are turbofans with high BPR, found in most commercial aircraft. Some turbofan’s model based design methods have being published (Henke et al. 2018). The biggest contribution to fuel burn reduction in recent commercial aircraft comes from new turbofan technologies, with higher BPRs. Rolls-Royce is working on the designs Advance (2020) with an expected reduction of 20% in fuel burn and \(\hbox {CO}_2\), and Ultrafan (2025) with expected 25%, both relative to the engine Trent 800 (Norris 2017b). Safran works on the Ultra-High-Bypass Ratio (UHBR) design, with extensive use of composite materials to achieve a BPR of 15, and an expected reduction of up to 25% in fuel burn relative to conventional engines (Vetters et al. 2014). General Electric works on the GE9X design with expected improvement in efficiency of 10% relative to previous design (Norris 2017a; IATA 2019).

General Electric Catalyst is a turbo-prop ICE that claims to explore the full range of pitch using a Full Authority Digital Engine Control (FADEC) with integrated propeller control for an improvement of 15% in fuel consumption (GE Aviation 2020). Rolls-Royce has developed ground tests on a hybrid system with the M250 gas turbine, an engine usually employed on helicopters. Three operating modes: Series, Parallel and Turbo-Electric, will produce a power from 500 kW to 1 MW to be used on propulsion for eVTOLs, general aircraft and hybrid helicopters (Rolls-Royce 2019).

The vibrations of reciprocating engines are suitable for small aircraft (MTOW until 1,250 kg), in low-speed and short-range operations. Wankel rotary engine (RE) is gaining acceptance with lower level of vibrations (González Espasandín et al. 2014). It is a four-stroke rotary combustion ICE, with vantages such as simple structure, multi-fuel, higher speed, high power density, low noise and low vibration (Chen et al. 2017; Yang et al. 2018a). A triangular-shaped rotor coupled to an eccentric shaft accomplishes a sinusoidal variation of volume in the rotor housing. This power section generates the output torque and drives the cooling and lubrication systems (Yewale et al. 2017). However, incomplete combustion, high fuel consumption and poor emissions are some issues. REs are more suitable in mobile electricity generators, hybrid vehicles and small aircraft. Over the past few years, the use of turbochargers, direct injection, and optimizing seals increased the performance of REs. Employing hydrogen fuel enrichment this technology achieved better combustion levels, lower CO emissions and controllable higher \(\hbox {NO}_x\) emissions (Chen et al. 2017; Yang et al. 2018a).

New propulsive designs, such as open rotor, are expected to reduce fuel burn and \(\hbox {CO}_2\) emissions by 30%. It is a hybrid between a propeller and a turbofan engine, characterized by two counter-rotating unshrouded fans. Open rotor can increase the BPR without significantly increasing the weight. Research is working on reducing the higher noise levels especially at takeoff compared with conventional turbofan, and it is envisaged to EIS on 2030 (Pitera et al. 2011; IATA 2019; Liu 2013).

The full annular BLI is other approach where the fuselage acts as a propulsive thrust. Studies performed with this technology expect a fuel burn reduction of 8.5% (Gipson 2017; Marien et al. 2018). The engines are located near the rear of the aircraft to increase propulsive efficiency by ingesting slower air from the fuselage or wing boundary layer, which changes the pressure distribution upstream, increasing the propulsion efficiency and decreasing the drag (Brelje and Martins 2019; IATA 2019). However, BLI benefits are very sensitive to inlet distortion (Liu 2013).

COVID-19 is the biggest shock on aviation since WW2, with an estimated shrunk of 66% in 2020. Global passenger flown reduced dramatically, much more than global cargo. Baseline forecast is that the pre-COVID-19 levels be recovered on 2023 (Pearce 2020). The global pandemic has slowed down the air traffic growth, and the most probable effect will be to postpone the greener aviation development.

ICEs supplied by biofuels may help to achieve environmental goals (Welstead et al. 2017). Research efforts have developed environmentally friendly sustainable aviation fuels (SAF) that produces up to 80% less \(\hbox {CO}_2\) emissions than conventional jet fuel. Several approaches from biogenic sources are being tested, as well as non-biogenic, such as power-to-liquid. The main drawback is that these fuels are produced at a non-competitive cost (IATA 2019).

Cheap kerosene is a big obstacle to a more rapid progress on electric flying, but may be charged with a tax over \(\hbox {CO}_2\) emissions. Studies about SAF technologies state that HEP aircraft with 40– passengers will be a reality in the medium-term, while bigger airplanes would keep flying powered by ICEs, but fueled with synthetic kerosene (Amelang 2018).