Abstract

TiO2 nanocrystalline thin films have various applications, among them dye-sensitized solar cells are more promising and low-cost alternative to conventional inorganic photovoltaic devices. TiO2 nanocrystalline thin films have been sensitized with the natural dye (malvidin-3-fructoside) extracted from grape fruits. The interaction between the semiconductor and the dye has been studied. The maximum absorption band of grape extract at 525 nm has been shifted to 545 nm after incorporation of the dye indicating interaction of the dye molecules with TiO2. The grape extract has polyphenolic anthocyanin pigment (malvidin-3-fructoside), which has carboxylic and hydroxyl groups that can attach effectively to the surface of TiO2 film. The dye-sensitized TiO2-based solar cell sensitized using grape dye exhibited a Jsc of 4.06 mA/cm2, Voc of 0.43 V, FF of 0.33 and efficiency of 0.55 %. Natural dye-sensitized TiO2 photo electrodes present the prospect to be used as an environment-friendly, low-cost alternative system.

Similar content being viewed by others

Introduction

Nanocrystalline TiO2 films have attracted scientific and technological interests because of their potential applications in the fields of photo electronic optical devices, solar cells, gas sensors, photocatalysts and biomaterials [1–3]. TiO2 is the best photo-catalyst so far, that absorbs the light at shorter wavelength below 400 nm, due to its wide band gap. Dye-sensitized solar cell, a device converting light energy to electrical energy by imitating photosynthesis of plants [4], was firstly developed by Gratzel’s group [5–7]. It is widely known as a low-cost and easy-assembly solar cell, in which both synthetic and natural dyes can be used as a sensitizer. Electrical energy is generated when the cell is exposed to sunlight. Electrons in dye molecules are excited and then injected to the conduction band of a wide band gap (TiO2) n-type semiconductor on which the dye molecules adsorb. These electrons migrate through the host semiconductor particles until they reach the collector; also the holes simultaneously generated are reduced by a redox electrolyte or hole carrier at the back electrode (Pt). Because of low material cost, simple preparation, and lack of heavy metals, natural dyes are more favorable to be applied in such device [8–12].

Solar cells are the basic block of solar array where the absorption of light quanta of specific energy results in generation of charge carriers. Due to absorption of sun light, dye molecules get excited from the highest occupied molecular orbital’s (HOMO) to the lowest unoccupied molecular orbital’s (LUMO).

Once an electron injected into the conduction band of the wide band gap semiconductor nano structured TiO2 film, the dye molecule (photosensitizer) become oxidized.

The injected electron is transported between the TiO2 nanoparticles and then gets extracted to a load where the work done is delivered as an electric energy.

To mediate electron between the TiO2 photoelectrode and the platinum counter electrode, electrolyte containing I−/\( {\text{I}}_{3}^{ - } \) redox ions is used to fill the cell. Therefore, the oxidized dye molecules (photosensitizer) are regenerated by receiving electrons from the I− ion redox mediator that will oxidized to \( {\text{I}}_{3}^{ - } \) (Tri-iodide ions).

The \( {\text{I}}_{3}^{ - } \) substitutes the donated electron internally with that from the external load and gets reduced back to I− ion.

Therefore, generation of electric power in dye-sensitized solar cell causes no permanent chemical change or transformation. The conducting electrodes are prepared such that they posses low-sheet resistance and very high transparency in order to facilitate high solar cell performance [13]. Figure 1 shows the structure of a dye-sensitized solar cell.

Anthocyanins consists a large family of widespread flavonoids in plants and they are responsible for many fruit and floral colors that are observed in nature. Chemically, these flavonoids are most commonly based on six anthocyanidins: pelargonidin, cyanidin, peonidin, delphinidin, petunidin and malvidin [14]. Interest in the anthocyanins has increased because of their potential as natural colorants and non-toxicity. They have bright attractive colors, and they are water-soluble. Acylated anthocyanin pigments show greater stability during processing and storage. Because of the presence of acylated groups in the structure of anthocyanins, it is believed that they can protect the oxonium ion from hydration, thereby prevent the formation of hemiketal (pseudobase) or chalcone forms. Anthocyanin pigments were found in 1835 for the first time. In 1916, Wehldale proposed anthocyanin flavanons formation pathway, since they were products of shikimic acid cycle. Willstatter and Zollinger [15, 16] reported malvidin 3-fructoside as the major pigment in grapes, and malvidin 3,5-diglucoside and malvidin as the minor ones. Anthocyanins from grapes include mono and diglucosides of five different aglycones with the addition of monoacylation [14]. The structure of malvidin 3-fructoside is shown in Fig. 2.

Sol–gel dip coating method has been used because of the low-cost equipments involved, lower growth temperatures and reproducibility. Many sensitizers have been used by different workers to sensitize TiO2 nanoparticles for solar cell applications. In this paper, we report a simple route to synthesize TiO2 nanoparticles. TiO2 nanoparticles have been used as photoelectrode material to fabricate the dye-sensitized solar cells. The use of non-toxic natural pigments as sensitizers would definitely enhance the environmental and economic benefits of this alternative form of solar energy conversion. Natural dye-sensitized solar cells are a promising class of photovoltaic cells with the capability of generating green energy at low production cost since no vacuum systems or expensive equipment are required in their fabrication. In addition, natural dyes are abundant, easily extracted and safe materials.

Experimental

To prepare the photo-anode of dye-sensitized solar cells, the indium-doped tin oxide conducting (ITO) glass sheet (Asahi Glass; Indium-doped SnO2, sheet resistance: 15 U/square) was first cleaned in a detergent solution using an ultrasonic bath for 15 min, rinsed with double distilled water and then dried. The matrix sol was prepared by mixing 0.695 ml of titanium (IV) isopropoxide with 15 ml of isoproponal at room temperature and stirred for half an hour. 0.135 ml of glacial acetic acid is added drop wise and stirred vigorously for 2 h to obtain a homogeneous mixture of TiO2 sol. The prepared sol was deposited on the Indium-doped tin oxide (ITO) glass plate by sol–gel dip coating method. The film was dried at 80 °C for 30 min in air and then annealed at 500 °C in a muffle furnace. For grapes a dye extract preparation, well cleaned grape fruits were mixed with 250 ml ethanol and were kept for 12 h at room temperature. Then residual parts were removed by filtration. The ethanol fraction was separated and few drops of concentrated HCl was added so that the solution became deep red color (pH < 1). This was directly used as dye solution for sensitizing TiO2 electrodes.

Crystallinity and phase analysis of the films were carried out using X-ray diffraction method (Rigaku Rint 2000 series). Energy dispersive X-ray analysis (EDAX) and structural studies have been carried out using transmission electron microscope (JEOL, JEM-2100). Transmission spectra have been recorded using UV–VIS–NIR spectrophotometer (Jasco V-570). Lithium iodide, iodine and acetonitrile purchased from Sigma-Aldrich have been used as received for the preparation of electrolyte. The redox electrolyte with [\( {\text{I}}_{3}^{ - } \)]/[I−] 1:9 was prepared by dissolving 0.5 M LiI and 0.05 M I2 in acetonitrile solvent. Since LiI is extremely hygroscopic, electrolytes were prepared in a dry room maintained at dew point of 60 °C. The counter electrode was prepared by using platinum chloride as follows: the H2PtCl6 solution in isopropanol (2 mg/ml) was deposited onto the ITO glass by spin coating method. TiO2 electrode annealed at 500 °C was immersed in the extracted dye solution at room temperature for 24 h in the dark, since the grape dye extract is not stable under prolonged illumination of light. The electrode was then rinsed with ethanol to remove the excess dye present in the electrode and then the electrode was dried. The counter electrode was placed on the top of the TiO2 electrode, such that the conductive side of the counter electrode facing the TiO2 film with a spacer separating the two electrodes. The two electrodes were clamped firmly together using a binder clip. Now the prepared liquid electrolyte solution was injected into the space between the clamped electrodes. The electrolyte enters into the cell by capillary action. This resulted in the formation of sandwich type cell. Natural dye-sensitized TiO2-based solar cells have been fabricated with area of 0.25 cm2, and it was found that the cell efficiency was independent of cell area in this range as reported by Yamazaki et al. [17]. The J–V characteristics of the cell were recorded using a Keithley 4200-SCS meter. A xenon lamp source (Oriel, USA) with an irradiance of 100 mW/cm2 was used to illuminate the solar cell (equivalent to AM1.5 irradiation).

Results and discussion

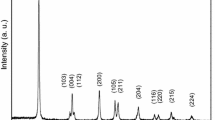

Figure 3 shows the X-ray diffraction pattern of the sol–gel prepared TiO2 films, annealed at 500 °C. A narrow peak at 25.35° corresponding to (101) reflection of the anatase phase of TiO2 has been observed in the diffraction pattern. The observed peaks corresponds to (1 0 1), (0 0 4), (2 0 0), (1 0 5), (2 1 1) and (2 0 4) which represent only anatase phase of TiO2. No peaks corresponding to the rutile or brookite phase has been observed. The grain size has been calculated using Scherer’s formula [18].

where D is the grain size, K is a constant taken to be 0.94, λ is the wavelength of the X-ray radiation (λ = 1.51 Ǻ), β is the full width at half maximum and θ is the angle of diffraction. The grain size was found to be 33 nm for the film annealed at 500 °C. The annealing temperature facilitates the subsequent crystal growth process, accompanied by the diffusion of titania species forming big size anatase crystals formed by merging of some adjacent mesopores. At the same time, the spatial confinement by mesopore arrays controls the formation and growth of anatase phase, leading to a more or less uniform distribution of titania nanocrystals.

Energy dispersive X-ray (EDAX) spectra of nanocrystalline TiO2 thin film is shown in Fig. 4. The compositional analysis of TiO2 thin films shows the presence of 32.7 at% of Ti and 67.3 at% of O. Figure 5 shows the transmission electron microscope images of the TiO2 thin film annealed at 500° C. Figure 5a shows the presence of close-packed agglomerated nanoparticles of uniform size which causes the mesoporous structure. This accumulation of nanoparticles creates narrow channels that may serve as electronic injection membranes [19]. The mesoporous structure, which provides a large surface area for adsorbing the dye, has been achieved in the present study, although no polymer was added to make pores. The prepared TiO2 films exhibited good mechanical strength, had good adherence to the substrate and could not be easily erased by hand. Figure 5b shows the high-resolution transmission electron microscope (HRTEM) image of TiO2 thin films. The interplanar distance has been calculated using the lattice fringes and is found to be 0.33 nm which corresponds to (101) lattice plane of anatase phase. Selective area electron diffraction pattern is used to learn about the crystal properties of a particular region. Figure 5c shows the selective area electron diffraction pattern of the nanocrystalline TiO2 thin film and the presence of rings with discrete spots suggest that the TiO2 nanocrystalline film is made of small particles of uniform size with anatase phase.

Figure 6a–c shows atomic force microscope images of the TiO2 thin films annealed 400, 450 and 500 °C. The image shows well-defined particle-like features with granular topography and indicates the presence of small crystalline grains. Because of the heat treatment, the nano crystalline phase has been formed and this has led to the appearance of grains making the films to have higher surface roughness. The root mean square surface roughness of the film was found to be 19, 27 and 32 nm for the TiO2 films annealed at 400, 450 and 500 °C.

To discriminate the local order characteristics of the TiO2 films, we carried out non-resonant Raman spectroscopy studies. The technique is non-destructive, capable to elucidate the titania structural complexity as peaks from each crystalline phase is clearly separated in frequency, and therefore the anatase and rutile phases are easily distinguishable. Figure 7 shows the Raman spectra of the nanocrystalline TiO2 sample annealed at 500 °C. Raman peaks originate from the vibration of molecular bonds, that is, vibrational mode Eg and A1g peaks, which are related to different crystal planes. According to factor group analysis, anatase has six Raman active modes (A1g + 2B1g + 3Eg). Ohsaka et al. [20] have reported the Raman spectra of an anatase TiO2 and have stated that six allowed modes appear at 144 cm−1 (Eg), 197 cm−1 (Eg), 399 cm−1 (B1g), 513 cm−1 (A1g), 519 cm−1 (B1g), and 639 cm−1 (Eg). The vibrational peaks of the nanocrystalline TiO2 samples at 143, 197, 396, 519, 638 cm−1 and the absence of overlapped broad peaks show that the material is well crystallized, with low number of imperfect sites. These peaks are unambiguously attributed to the anatase modification. A special attention must be given to the Raman peaks observed at 143, 197, 396, 519, 638 cm−1 which are all slightly shifted, probably due to a smaller size of TiO2 nanocrystalline particles. The peak at 513 and 517 cm−1 are very close to each other. The main spectral features of samples annealed at different temperatures are closely similar which mean that the prepared samples posses a certain degree of long range order of the anatase phase. The spectra vary symmetrically with grain size. It deteriorates with spectroscopic lines broadening and merging, line intensity decreases and position shifting with decrease in annealing temperature. However, the spectrum of sample showing the band broadening with decrease in intensity [21].

Optical absorption spectra of grape fruits and grape fruits absorbed TiO2 nanocrystalline thin films are shown in Fig. 8. It is seen that the absorption peak of grape fruits extract is maximum at 510 nm. The presence of the absorbance peak at 530 nm in grape fruits sensitized TiO2 nanocrystalline thin films confirms the incorporation of dye into the TiO2 film. Malvidin-3-fructoside flavanoid is responsible for the absorption of light. This chemical attachment affects the energy levels of the highest occupied molecular level (HOMO) and the lowest unoccupied molecular level (LUMO) of the anthocyanidin molecule [22], which eventually affects the band gap of these materials and this results in a shift in the absorption peak of the absorption spectra. It is seen that absorption coefficients of grape fruits extract is about 14 times higher than that of the N-719 dye used in high efficiency dye-sensitized solar cells [23]. The absorption bands of the dye adsorbed TiO2 semiconductor films are shifted to longer wavelength when compared to the absorption spectra of the dye solution as shown in Fig. 8. The intensity of light absorption has been enhanced due to the interfacial Ti–O coupling which exists between the C=O, C–H, C–O, O–H bonding of dye molecules and TiO2 molecules [24].

Figure 9a, b shows the Fourier transform infrared spectra (FTIR) of grape extract, grape extract-sensitized TiO2 nanocrystalline thin films. The spectra have been recorded using FTIR 1600 infrared spectrophotometer, operating in the wave number range 800–4,400 cm−1. For the grape extract, the bands in the region of 1,651 cm−1 represents the amide group and the bands in the regions 2,900, 2,978 cm−1 represents the C–H bonding of the grape extract and a broad sharp peak is obtained in the region 3,371 cm−1 which corresponds to the hydrogen bonding. The bands in the region 1,381 cm−1 correspond to OH bonding. The bands in the region 1,273 and 1,087 cm−1 correspond to O–C bonding and the band at 879 cm−1 represents the C–H bonding in the grape extract. The grape extract-sensitized TiO2 nanocrystalline thin films shows a peak at 1,442 cm−1 which corresponds to the absorption band of TiO2 molecules [25]. The bands ranging from 2,854 to 3,363 cm−1 correspond to the C–H stretching due to methyl and methylene groups.

The J–V characteristics of TiO2 nanocrystalline thin films sensitized with natural dyes is shown in Fig. 10. The overall efficiency η of the grape dye cells are evaluated in terms of open circuit voltage (Voc), short circuit current (Jsc) and fill factor (FF) using the formula

where Jsc is the short circuit photocurrent density (mA cm−2), Voc the open circuit voltage (volts), Pin is the intensity of the incident light (Pin = 1 Wcm−2) and Jmax (mA cm−2) and Vmax (volts) are the maximum current density and voltage in the J–V curve, respectively, at point of maximum power output. The solar cell sensitized with grape extract dye exhibited a power conversion efficiency of 0.55 % with a short circuit current density (Jsc) of 4.06 mA/cm2, open circuit voltage (Voc) of 0.43 V and fill factor (FF) of 0.33.

Conclusion

TiO2 nanocrystalline thin films have been prepared by a simple sol–gel method. X-ray diffraction analysis reveals that the TiO2 nanocrystalline thin films exhibit anatase structure. The dyes extracted from grapes strongly absorb visible light at 510 nm and the absorption bands of the dye adsorbed TiO2 semiconductor films are shifted to longer wavelength and have been found to be suitable for the use as sensitizer in solar cells. The efficiency of the fabricated dye-sensitized solar cell using grapes extract is 0.55 %. Unlike artificial dyes, the natural ones are available, easy to prepare, low in cost, non-toxic, environmentally friendly and fully biodegradable.

References

Zhou, W., Du, G., Hu, P., Li, G., Wang, D., Liu, H., Wang, J., Robert, I., Lio, B.D., Jiang, H.: Nanoheterostructures on TiO2 nanobelts achieved by acid hydrothermal method with enhanced photocatalytic and gas sensitive performance. J. Mater. Chem. 21, 7937–7945 (2011)

Galstyan, V., Comini, E., Faglia, G., Sberveglieri, G.: TiO2 nanotubes: recent advances in synthesis and gas sensing properties. Sensors (Basel). 13(11), 14813–14839 (2014)

Gokilamani, N., Muthukumarasamy, N., Thambidurai, M., Ranjitha, A., Velauthapillai, D.: Utilization of natural anthocyanin pigments as photosensitizers for dye-sensitized solar cells. J. Sol–Gel. Sci. Technol. 66, 212–219 (2013)

Hagfeldt, A., Didriksson, B., Palmqvist, T., Lindstrom, H., Sodergren, S., Rensmo, H., Lindqist, S.E.: Verification of high efficiencies for the Gratzel cell. A 7 % efficient solar cell based on dye-sensitized colloidal TiO2 films. Sol. Energ. Mater. Sol. Cells 31, 481–488 (1994)

Nazeeruddin, M.K., Kay, A., Rodicio, I., Humphry-Baker, R., Muller, E., Liska, P., Vlachopoulos, N., Gratzel, M.: Conversion of light to electricity by cis-X2bis(2,20-bipyridyl-4,40-dicarboxylate)ruthenium(II) charge-transfer sensitizers (X = Cl−, Br−, I−, CN−, and SCN−) on nanocrystalline TiO2 electrodes. J. Am. Chem. Soc. 115, 6382–6390 (1993)

Barbe, C.J., Arendse, F., Comte, P., Jirousek, M., Lenzmanne, F., Shklover, V., Gratzel, M.: Nanocrystalline titanium oxide electrodes for photovoltaic applications. J. Am. Ceram. Soc. 80, 3157–3171 (1997)

Kalyanasundaram, K., Gratzel, M.: Applications of functionalized transition metal complexes in photonic and optoelectronic devices. Coord. Chem. Rev. 177, 347–414 (1998)

Gokilamani, N., Muthukumarasamy, N., Thambidurai, M., Ranjitha, A., Velauthapillai, D., Senthil, T.S., Balasundaraprabhu, R.: Dye-sensitized solar cells with natural dyes extracted from rose petals. J. Mater. Sci. Mater. Electron 24, 3394–3402 (2013)

Thambidurai, M., Muthukumarasamy, N., Velauthapillai, D., Lee, C.: Synthesis and characterization of flower like ZnO nanorods for dye-sensitized solar cells. J. Mater. Sci. Mater. Electron 24, 2367–2371 (2013)

Thambidurai, M., Muthukumarasamy, N., Velauthapillai, D., Lee, C.: Chemical bath deposition of ZnO nanorods for dye sensitized solar cell applications. J. Mater. Sci. Mater. Electron 24, 1921–1926 (2013)

Thambidurai, M., Muthukumarasamy, N., Velauthapillai, D., Lee, C.: Synthesis of garland like ZnO nanorods and their application in dye sensitized solar cells. Mater. Lett. 92, 104–107 (2013)

Gokilamani, N., Muthukumarasamy, N., Thambidurai, M., Ranjitha, A., Velauthapillai, D.: Solanum nigrum and Eclipta alba leaf pigments for dye sensitized solar cell applications. J. Sol–Gel. Sci. Technol. 69(1), 17–20 (2014)

EbrahimJasim, Khalil: Natural dye-sensitized solar cell based on nanocrystalline TiO2. Sains Malaysiana 41(8), 1011–1016 (2012)

Heidari, R. , Khalafi, R. , Dolatabadzadeh, N.: Anthocyanin pigments of Siahe Sardasht grapes. J. Sci. Islamic Repub. Iran. 15(2), 113–117 (2004)

Willstatter, R., Zollinger, E.H.: VI. Uber die Farbstoffe der Weintraube und der Heidelbeere. Ann. Chem. Liebigs. 408, 83–109 (1915)

Willstatter, R., Zollinger, E.H.: XI. Uber die Farbstoffe der Weintraube und der Heidelbeere, II. Ann. Chem. Liebigs. 412, 195–216 (1916)

Eiji, Y., Masaki, M., Naomi, N., Noritsugu, H., Masashi, S., Osamu, K.: Utilization of natural carotenoids as photosensitizers for dye sensitized solar cells. Sol. Energ. 81, 512–516 (2007)

Sapanhel, L., Anderson, M.A.: Synthesis of porous quantum-size cadmium sulfide membranes: photoluminescence phase shift and demodulation measurements. J. Am. Chem. Soc. 112, 2278–2284 (1990)

Cao, Y.M., Bai, Y., Yu, Q.J., Cheng, Y.M., Liu, S., Shi, D., Gao, F., Wang, P.: Dye-sensitized solar cells with a high absorptivity ruthenium sensitizer featuring a 2-(hexylthio) thiophene conjugated bipyridine. J. Phys. Chem. C 113(15), 6290–6297 (2009)

Ohsaka, Toshiaki: Temperature dependence of the Raman spectrum in anatase TiO2. J. Phys. Soc. Jpn. 48, 1661–1668 (1980)

Šćepanović, M.J., Grujić-Brojčin, M., Dohčević-Mitrović, Z.D., Popović, Z.V.: Characterization of anatase TiO2 nanopowder by variable–temperature Raman spectroscopy. Sci. Sinter. 41, 67–73 (2009)

Sheng, Meng, Jun, Ren, Efthimios, Kaxiras: Natural dyes adsorbed on TiO2 nanowire for photovoltaic applications: enhanced light absorption and ultrafast electron injection. Nano. Lett. 8(10), 3266–3272 (2008)

Senthil, T.S., Muthukumarasamy, N., Velauthapillai, D., Agilan, S., Thambidurai, M., Balasundaraprabhu, R.: Natural dye (cyanidin 3-O-glucoside) sensitized nanocrystalline TiO2 solar cell fabricated using liquid electrolyte/quasi-solid-state polymer electrolyte. Renew. Energ. 36, 2484–2488 (2011)

Fernando, J.M.R.C., Senadeera, G.K.R.: Natural anthocyanins as photosensitizers for dye sensitized solar devices. Curr. Sci. 95, 663–666 (2008)

Gratzel, M.: Perspectives for dye-sensitized nanocrystalline solar cells. Prog. Photovolt. Res. Appl. 8, 171–185 (2000)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Gokilamani, N., Muthukumarasamy, N., Thambidurai, M. et al. Grape pigment (malvidin-3-fructoside) as natural sensitizer for dye-sensitized solar cells. Mater Renew Sustain Energy 3, 33 (2014). https://doi.org/10.1007/s40243-014-0033-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-014-0033-6