Abstract

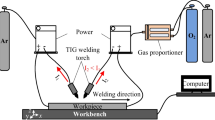

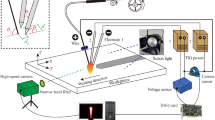

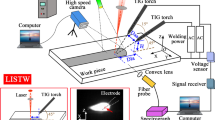

Multi-electrode welding processes are used in various industrial fields for higher productivity. These processes can use many combinations of welding methods, current values and polarities, and electrode alignments. However, this complicates welding phenomena. In this research, we focused on the tandem tungsten inert gas (TIG) arc, which is a relatively simple multi-electrode welding process. We performed a numerical investigation into the tandem TIG arc plasma and weld pool formation to clarify the phenomena involved. The weld spot of a tandem TIG weld is ellipsoidal in appearance and is deeper than that of a single-electrode TIG weld. Reduction in the shear stress of the plasma flow in the tandem TIG weld leads to a deeper penetration. Furthermore, the influence of the electrode alignment is calculated, and it is determined that the weld spot appearance significantly changes. The appearance is strongly related to the arc plasma shape. These numerical results show good agreement with the experimental results, which proves that our model has relatively high reliability.

Similar content being viewed by others

References

Fujii H, Sato T, Lu S, Nogi K (2008) Development of an advanced A-TIG (AA-TIG) welding method by control of Marangoni convection. Mater Sci Eng 495:296–303

Chae HB, Kim CH, Kim JH, Rhee S (2008) The effect of shielding gas composition in CO2 laser-gas metal arc hybrid welding. Proc I MechE Part B J Eng Manuf 222:1315–1324

Kataoka T, Ikeda R, Yasuda K, Hirata Y (2009) Development of low spatter CO2 arc welding process with high frequency pulse current. Sci Technol Weld Join 14:740–746

Era T, Ide A, Uezono T, Hirata Y (2009) Controlled bridge transfer (CBT) gas metal arc process for steel sheets joining. Sci Technol Weld Join 14:493–499

Nomura K, Morisaki K, Hirata Y (2009) Magnetic control of arc plasma and its modeling. Welding World 53:181–187

Ueyama T, Uezono T, Era T, Tanaka M, Nakata K (2009) Solution to problems of arc interruption and arc length control in tandem pulsed gas metal arc welding. Sci Technol Weld Join 14:305–314

Zhang G, Xiong J, Gao H, Wu L (2011) Reconstruction of emission coefficients for a non-axisymmetric coupling arc by algebraic reconstruction technique. J Quant Spectrosc Radiat Transf 112:92–99

Gao Y, Yu Q, Jiang W, Wan X (2010) Reconstruction of three-dimensional arc-plasma temperature fields by orthographic and double-wave spectral tomography. Optics Laser Techn 42:61–69

Rouffet ME, Wendt M, Goett G, Kozakov R, Schoepp H, Weltmann KD, Uhrlandt D (2010) Spectroscopic investigation of the high-current phase of a pulsed GMAW process. J Physics D App Phys 43:434003

Fan HG, Kovaceivic R (2004) A unified model of transport phenomena in gas metal arc welding including electrode, arc plasma and molten pool. J Physics D App Phys 37:2531–2544

Schnick M, Fussel U, Hertel M, Spille-Kohoff A, Murphy AB (2011) Numerical investigations of arc behavior in gas metal arc welding using ANSYS CFX. Front Mater Sci 5(2):98–108

Schnick M, Fuessel U, Hertel M, Haessler M, Spille-Kohoff A, Murphy AB (2010) Modelling of gas-metal arc welding taking into account metal vapour. J Phys D Applied Phys 43:434008

Tsujimura Y, Tashiro S, Tanaka M (2011) Numerical model of gas metal arc with metal vapor for heat source in welding. Trans JWRI 40(1):25–29

Yamamoto K, Tanaka M, Tashiro S, Nakata K, Murphy AB (2009) Metal vapor behavior in GTA welding of a stainless steel considering the Marangoni effect. T Electr Electr Eng 4:497–503

Hu J, Guo H, Tsai HL (2008) Weld pool dynamics and the formation of ripples in 3D gas metal arc welding. Int J Heat Mass Transf 51:2537–2552

Hu J, Tsai HL (2008) Modeling of transport phenomena in 3D GMAW of thick metals with V groove. J Phys D Applied Phys 41(065202):10

Rao ZH, Zhou J, Liao SM, Thai HL (2010) Three-dimensional modeling of transport phenomena and their effect on the formation of ripples in gas metal arc welding. J Appl Phys 107(054905):14

Dong W, Lu S, Li D, Li Y (2011) GTAW liquid pool convections and the weld shape variations under helium gas shielding. Int J Heat Mass Transf 54:1420–1431

Freton P, Gonzalez JJ, Gleizes A (2000) Comparison between a two- and a three-dimensional arc plasma configuration. J Phys D Applied Phys 33:2442–2452

Speckhofer G, Schmidt HS (1996) Experimental and theoretical investigation of high-pressure arcs—part II: the magnetically deflected arc (three-dimensional modeling). IEEE Trans Plasma Sci 24(4):1239–1248

Xu G, Hu J, Tsai HL (2008) Three-dimensional modeling of the plasma arc in arc welding. J Appl Phys 104(103301):9

Schnick M, Wilhelm G, Lohse M, Fussel U, Murphy AB (2011) Three-dimensional modeling of arc behavior and gas shield quality in tandem gas-metal arc welding using anti-phase pulse synchronization. J Phys D Applied Phys 44:185205

Ogino Y, Hirata Y, Nomura K (2011) Numerical analysis of the heat source characteristics of a two-electrode TIG arc. J Phys D Applied Phys 44:215202

Murphy AB (2011) A self-consistent three-dimensional model of the arc, electrode and weld pool in gas-metal arc welding. J Phys D Applied Phys 44:194009

Meyer GH (1973) Multidimensional Stefan problems. SIAM J Numer Anal 10(3):522–538

White RE (1983) A modified finite difference scheme for the Stefan problem. Math Comput 41(164):337–347

McKelliget J, Szekely J (1985) Heat transfer and fluid flow in the welding arc. Metallurgical Trans A 17:1139–1148

Debroy T, David SA (1995) Physical processes in fusion welding. Rev Mod Phys 67(1):85–112

Capitelli M, Devoto RS (1973) Transport coefficients of high-temperature nitrogen. The Phys Fluids 16(11):1835–1841

Murphy AB (2010) The effect of metal vapour in arc welding. J Phys D Applied Phys 43:434001

Cram LE (1985) Statistical evaluation of radiative power losses from thermal plasmas due to spectral lines. J Phys D Applied Phys 18:401–411

Menart J, Malik S (2002) Net emission coefficients for argon–iron thermal plasmas. J Phys D Applied Phys 35:867–874

McNallan MJ, Debroy T (1991) Effect of temperature and composition on surface tension in Fe-Ni-Cr alloys containing sulfur. Metall Mater Trans B 22:557–560

Sahoo P, Debroy T, McNallan MJ (1988) Surface tension of binary metal—surface active solute systems under conditions relevant to welding metallurgy. Metall Mater Trans B 19:483–491

A. A. Amsden and F. H. Harlow: The SMAC method: a numerical technique for calculating incompressible fluid flows. Los Alamos Science Laboratory report, 1970, LA-4370

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2357, recommended for publication by Study Group SG-212 “The Physics of Welding”.

Rights and permissions

About this article

Cite this article

Ogino, Y., Hirata, Y., Kawata, J. et al. Numerical analysis of arc plasma and weld pool formation by a tandem TIG arc. Weld World 57, 411–423 (2013). https://doi.org/10.1007/s40194-013-0040-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0040-8