Abstract

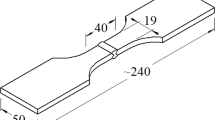

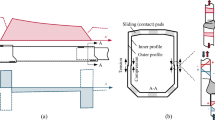

Welded structures made of high-strength steel offer benefits in fatigue strength for finite life applications. The high-cycle fatigue limit, however, depends mostly on the geometry, and the metallurgy of the notch is of little account. Therefore, an optimised weld process is required to achieve an improvement in the fatigue strength. This paper contributes to the field of fatigue behaviour of thin-walled, high-strength steel butt joints, with regard to an optimisation of the gas metal arc weld process. An existing methodology was extended to manufacture welded specimens with minimised production scatter. The majority of the butt joint samples were dynamically tested, with the root surface ground flush to plate, to study the effect of the weld process on fatigue. The investigated specimen were carefully analysed by metallographic studies along with hardness, distortion, and weld toe topography measurements. This facilitated in finding a relation between experimental fatigue life and the weld parameters. The nominal stress approach, including a benign, nonconservative thinness correction, and the recommended notch stress concept, were applied to assess the fatigue behaviour of the thin-walled, high-strength steel butt joints. The experimental results showed that in case of high-quality welds with negligable geometric notch factor, a small, but distinct influence of the filler metal on fatigue is observable. The highest fatigue strength for the investigated butt joint design was obtained with a high-strength metal-cored wire filler in combination with a three-component shielding gas.

Similar content being viewed by others

References

Hobbacher A (2008) Recommendations for fatigue design of welded joints and components, IIW-Doc. 1823–07

Stoschka M, Fössl T, Leitner M, Posch G (2012) Effect of high-strength filler metals on fatigue. Welding in the World 56(03/04):20–29

ISO 9692–1 (2003) Welding and allied processes—recommendations for joint preparation—Part 1: Manual metal-arc welding, gas-shielded metal-arc welding, gas welding, TIG welding and beam welding of steels

Radaj D, Sonsino CM, Fricke W (2006) Fatigue assessment of welded joints by local approaches, 2nd edn. Woodhead, Cambridge

Ørjasæter O (1995) Effect of plate thickness on fatigue of welded components, IIW-Doc. XIII-1582

ASTM International E739 (1998) Standard practice for statistical analysis of linear or linearized stress-life (S-N) or strain-life (ε-N) fatigue data (ASTM E739-91)

Bromiley PA Thacker NA (2002) The effects of an arcsin square root transform on a binomial distributed quantity, Tina Memo no. 2002–007, internal report, pp:1–8

Dengel D, Harig H (1980) Estimation of the fatigue limit by progressively-increasing load tests. Fatig Frac Eng Mat Struct 3(2):113–128

ISO 5817 (2003) Welding—fusion-welded joints in steel, nickel, titanium and their alloys (beam welding excluded)—quality levels for imperfections

Sonsino CM, Bruder T, Baumgartner J (2010) S-N lines for welded thin joints—suggested slopes and fat values for applying the notch stress concept with various reference radii. Weld World 54(11/12):375–392

Radaj D, Sonsino CM, Fricke W (2009) Recent developments in local concepts of fatigue assessment of welded joints. Int J Fatig 31:2–11

Pedersen MM, Mouristen OØ, Hansen MR, Andersen JG (2010) Experience with the notch stress approach for fatigue assessment of welded joints. Proceedings of the Swedish Conference on Light Weight Optimized Welded Structures, Borlänge, Sweden. pp:1–11

Fricke W, Kahl A (2007) Local stress analysis and fatigue assessment of bracket toes based on measured weld profile, IIW-Doc. XIII-2166-07/XV-1253-07

Pedersen MM, Mouristen OØ, Hansen MR, Andersen JG, Wenderby J (2007) Re-analysis of fatigue data for welded joints using the notch stress approach. International Journal of Fatigue 33:1620–1626

Costa JDM, Ferreira JAM, Abreu LPM (2010) Fatigue behaviour of butt welded joints in a high strength steel. Procedia Engineering 2:697–705

Cerit M, Kokumer O, Genel K (2010) Stress concentration effects of undercut defect and reinforcement metal in butt welded joint. Eng Fail Anal 17:571–578

Casavola C, Masellis D, Pappalettere C (2004) Residual stresses and fatigue strength of butt welded components, Proceedings of SEM X International Congress

Acknowledgments

Special thanks are given to the Austrian Research Promotion Agency (FFG), who founded the research project by funds of the Federal Ministry for Transport, Innovation and Technology (bmvit) and the Federal Ministry of Economics and Labour, and to all the industry partners for the supply of material and the fabrication work done. Financial support by the Austrian Federal Government and the Styrian Provincial Government, represented by Österreichische Forschungsförderungsgesellschaft mbH and Steirische Wirtschaftsförderungsgesellschaft mbH, within the research activities of the K2 Competence Centre on “Integrated Research in Materials, Processing and Product Engineering”, operated by the Materials Center Leoben Forschung GmbH under the frame of the Austrian COMET Competence Centre Programme, is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2268, recommended for publication by Commission II “Arc Welding and Filler Metals”.

Rights and permissions

About this article

Cite this article

Stoschka, M., Leitner, M., Posch, G. et al. Effect of high-strength filler metals on the fatigue behaviour of butt joints. Weld World 57, 85–96 (2013). https://doi.org/10.1007/s40194-012-0010-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-012-0010-6