Abstract

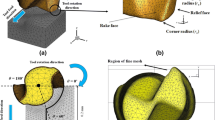

Micro-end milling is one of the widely used processes for producing micro features/components in micro-fluidic systems, biomedical applications, aerospace applications, electronics and many more fields. However in these applications, the forces generated in the micro-end milling process can cause tool vibration, process instability and even cause tool breakage if not minimized. Therefore, an accurate prediction of cutting forces in micro-end milling is essential. In this work, a finite element method based model is developed using ABAQUS/Explicit 6.12 software for prediction of cutting forces in micro-end milling with due consideration of tool edge radius effect, thermo-mechanical properties and failure parameters of the workpiece material including friction behaviour at tool-chip interface. Experiments have been performed for manufacturing of microchannels on copper plate using 500 µm diameter tungsten carbide micro-end mill and cutting forces are acquired through a dynamometer. Predicted cutting forces in feed and cross feed directions are compared with experimental results and are found to be in good agreements. Results also show that FEM based simulations can be applied to analyze size effects of specific cutting forces in micro-end milling process.

Similar content being viewed by others

References

X. Liu, R.E. DeVor, S.G. Kapoor, K.F. Ehmann, The mechanics of machining at the micro scale: assessment of the current state of the science. Trans. ASME J. Manuf. Sci. Eng. 126, 666–678 (2004)

D. Dornfeld, S. Min, Y. Takeuchi, Recent advances in mechanical micromachining. Ann. CIRP Manuf. Technol. 55(2), 745–769 (2006)

J. Chae, S.S. Park, T. Freiheit, Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 46(3–4), 313–332 (2006)

M. Rahman, A.S. Kumar, J.R.S. Prakash, Micro milling of pure copper. J. Mater. Process. Technol. 116, 39–43 (2001)

F. Ducobu, E. Filippi, E. Rivière-Lorphèver, Chip formation in micro-milling, in Proceedings of the 8th National Congress on Theoretical and Applied Mechanics, May 28–29, Brussels, Belgium, pp. 333–339 (2010)

J. Wang, Y. Gong, G. Abba, J.F. Antoine, J. Shi, Chip formation analysis in micromilling operation. Int. J. Adv. Manuf. Technol. 45, 430–447 (2009)

M.A. Camara, J.C.C. Rubio, A.M. Abrao, J.P. Davim, State of the art on micromilling of materials, a review. J. Mater. Sci. Technol. 28(8), 673–685 (2012)

M.S. Shunmugam, Machining challenges: macro to micro cutting. J. Inst. Eng. India Ser. C (2015). doi:10.1007/s40032-015-0182-0

P.J. Arrazola, T. Özel, D. Umbrello, M. Davies, I.S. Jawahir, Recent advances in modelling of metal machining processes. Ann. CIRP Manuf. Technol. 62, 695–718 (2013)

R.S. Anand, K. Patra, Modeling and simulation of mechanical micro-machining—a review. Mach. Sci. Technol. 18, 323–347 (2014)

M.T. Zaman, A.S. Kumar, M. Rahman, S. Sreeram, A three dimensional analytical cutting force model for micro end milling operation. Int. J. Mach. Tools Manuf. 46, 353–366 (2006)

I.S. Kang, J.S. Kim, J.H. Kim, M.C. Kang, Y.W. Seo, A mechanistic model of cutting force in the micro end milling process. J. Mater. Process. Technol. 187–188(12), 250–255 (2007)

I.S. Kang, J.S. Kim, Y.W. Seo, Cutting force model considering tool edge geometry for micro end milling process. J. Mech. Sci. Technol. 22, 293–299 (2008)

G. Bissacco, H.N. Hansen, J. Slunsky, Modelling the cutting edge radius size effect for force prediction in micro milling. Ann. CIRP Manuf. Technol. 57, 113–116 (2008)

M.B.G. Jun, C. Goo, M. Malekian, S. Park, A new mechanistic approach for micro end milling force modeling. Trans. ASME J. Manuf. Sci. Eng. 134, 011006-1-9 (2012)

Y.V. Srinivasa, M.S. Shunmugam, Mechanistic model for prediction of cutting forces in micro end-milling and experimental comparison. Int. J. Mach. Tools Manuf. 67, 18–27 (2013)

T. Zhang, Z. Liu, C. Xu, Theoretical modeling and experimental validation of specific cutting force for micro end milling. Int. J. Adv. Manuf. Technol. 77, 1433–1441 (2015)

G.R. Johnson, W.H. Cook, A constitutive model and data for metals subjected to large strains, high strain rates and high temperature, in Proceedings of the Seventh International Symposium on Ballistics, The Haque, The Netherlands, pp. 541–547 (1983)

G.R. Johnson, Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 20(1), 31–48 (1985)

X. Lai, H. Li, C. Li, Z. Lin, J. Ni, Modeling and analysis of micro scale milling considering size effect, micro cutter edge radius and minimum chip thickness. Int. J. Mach. Tools Manuf. 48(1), 1–14 (2008)

K.W. Kim, W.Y. Lee, H. Sin, A finite element analysis for the characteristics of temperature and stress in micro-machining considering the size effect. Int. J. Mach. Tools Manuf. 39, 1507–1524 (1999)

H. Ding, N. Shen, Y.C. Shin, Experimental evaluation and modeling analysis of micromilling of hardened H13 tool steels. Trans. ASME J. Manuf. Sci. Eng. 133, 041007-1-11 (2011)

T. Özel, T. Thepsonthi, D. Ulutan, B. Kaftanoglu, Experiments and finite element simulations on micro-milling of Ti–6Al–4V alloy with uncoated and cBN coated micro-tools. Ann. CIRP Manuf. Technol. 60, 85–88 (2011)

X. Jin, Y. Altintas, Prediction of micro-milling forces with finite element method. J. Mater. Process. Technol. 212(3), 542–552 (2012)

T. Thepsonthi, T. Özel, An integrated toolpath and process parameter optimization for high-performance micro-milling process of Ti–6Al–4V titanium alloy. Int. J. Adv. Manuf. Technol. 75, 57–75 (2014)

X. Jing, H. Li, J. Wang, Y. Tian, Modelling the cutting forces in micro-end-milling using a hybrid approach. Int. J. Adv. Manuf. Technol. 73, 1647–1656 (2014)

ABAQUS, Theory and analysis user’s manual. Version 6.12-3 (2012)

M.S.J. Hashmi, Comprehensive Materials Processing, vol. 13 (Elsevier, UK, 2014)

K. Kadirgama, R.A. Bakar, M. Rahman, B. Mohamad, Modeling of Residual Stress, Finite Element Analysis—From Biomedical Applications to Industrial development, ed. By D. Moratal, (InTech, Europe, 2012), pp. 369–378

Acknowledgments

The present work is the extended version of the paper entitled “MODELING AND ANALYSIS OF CUTTING FORCES IN MICRO END MILLING” presented in the 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) organised during December 12th–14th, 2014, at Indian Institute of Technology Guwahati, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pratap, T., Patra, K. Finite Element Method Based Modeling for Prediction of Cutting Forces in Micro-end Milling. J. Inst. Eng. India Ser. C 98, 17–26 (2017). https://doi.org/10.1007/s40032-016-0232-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0232-2