Abstract

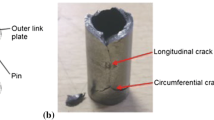

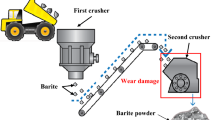

Failure analysis of a tool steel (AISI A2) beater head of an impact crusher and development of suitable heat treatment process to improve its performance have been presented. The beater heads were failing prematurely by brittle fracture from its pin-hole locations. The investigation consisted of visual inspection, fractography, chemical analysis, characterization of microstructures using optical and scanning electron microscopes (SEM), EDS analysis, and determination of micro-hardness profile. Microstructural characterization using SEM and EDS analysis revealed significant amount of coarse continuous Cr-carbide networks in the martensite matrix. It increased hardness (64 HRC) as well as heterogeneity of the matrix as depicted by the micro-hardness profile, and decreased the toughness (3 J) since coarse carbide networks are very hard and brittle. The austenitizing temperature as well as tempering temperature of heat treatment was found lower at the manufacturer’s end. The new recommended heat treatment resulted in lower amount of discontinuous Cr-carbides along with significant amount of fine precipitates uniformly distributed throughout the matrix which led to an optimum combination of both hardness (59 HRC) and toughness (6.5 J) required for the application. The beater heads manufactured following the recommended heat treatment exhibited better performance (life increased by 4 times) compared to the earlier ones.

Similar content being viewed by others

References

Y. Umucu, V. Deniz, S. Cayirli, A new model for comminution behavior of different coals in an impact crusher. Energy Sources A 36(13), 1406–1413 (2014)

M. Pellizzari, A. Molinari, The application-oriented heat treatment of tool steels. Mater. Manuf. Process. 24(7–8), 723–728 (2009)

B. Smoljan, An analysis of relationships between behavior and microstructure constitution of hot-work tool steel. Mater. Manuf. Process. 24(7–8), 786–790 (2009)

P. Hansson, Modern prehardened tool steels in die-casting applications. Mater. Manuf. Process. 24, 824–827 (2009)

A.E. Karantzalis, A. Lekatou, H. Mavros, Microstructural modifications of as-cast high-chromium white iron by heat treatment. J. Mater. Eng. Perform. 18, 174–181 (2009)

J.O. Agunsoye, V.S. Aigbodion, O.S. Sanni, Effect of heat treatment on microstructure and mechanical properties of NF 6357A cast alloy for wear resistance application. J. Miner. Mater. Charact. Eng. 10(11), 1077–1086 (2011)

C.R. Gagg, Premature failure of thread rolling dies: material selection, hardness criteria and case studies. Eng. Fail. Anal. 8, 87–105 (2001)

M.F. Mirjana, Iron-chromium-carbon-vanadium white cast irons—microstructure and properties. Chem. Ind. 68(4), 413–427 (2014)

G. Mukhopadhyay, S. Bhattacharyya, Cracking of a tool steel guide roller in a Bar Mill. J. Mater. Eng. Perform. 12, 594–603 (2012)

D. Viale, J. Béguinot, F. Chenou, G. Baron, Optimizing microstructure for high toughness cold-work tool steels, in Proceedings of the 6th International Tooling Conference, Use of Tool Steels: Experience and Research, ed. by J. Bergstrom, G. Fredriksson, M. Johansson, O. Kotik, F. Thuvander (Karlstad University, Karlstad, 2002)

N. Mebarki, P. Lamesle, D. Delagnes, C. Levaillant, F. Delmas, Relationship between microstructure and mechanical properties of a 5%Cr hotwork tool steel, in Proceedings of the 6th International Tooling Conference, Use of Tool Steels: Experience and Research, ed. by J. Bergstrom, G. Fredriksson, M. Johansson, O. Kotik, F. Thuvander (Karlstad University, Karlstad, 2002)

A. Ray, D. Mukherjee, B. Sarkar, S. Mishra, Influence of microstructure on the premature failure of a second-intermediate sendzimir mill drive roll. J. Mater. Eng. Perform. 3(5), 649–656 (1994)

K.M. Ibrahim, M.M. Ibrahim, Heat treatment in high chromium white cast iron Ti alloy. J. Metall. 2014, Article ID 856408 (2014). doi:10.1155/2014/856408

N.F. Garza-Montes-de-Oca, R. Colás, W.M. Rainforth, On the damage of a work roll grade high speed steel by thermal cycling. Eng. Fail. Anal. 18, 1576–1583 (2011)

M.M. Dhobe, I.K. Chopde, C.L. Gogte, Investigations on surface characteristics of heat treated tool steel after wire electro-discharge machining. Mater. Manuf. Process. 28(10), 1143–1146 (2013)

F.J. Belzunce, A. Ziadi, C. Rodriguez, Structural integrity of hot strip mill rolling rolls. Eng. Fail. Anal. 11, 789–797 (2004)

Bureau of Indian Standards, Method for Charpy Impact Test (V notch) for Metallic Material, IS 1757 (Bureau of Indian Standards, New Delhi, 1988)

ASTM International, Standard Specification for Tool Steels Alloy, ASTM A681-08 (ASTM International, West Conshohocken, 2008)

R. Schneider, J. Perko, G. Reithofer, Heat treatment of corrosion resistant tool steels for plastic moulding. Mater. Manuf. Process. 24, 903–908 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mukhopadhyay, G., Palit, P. & Bhattacharyya, S. Development of AISI A2 Tool Steel Beater Head for an Impact Crusher in a Sinter Plant. Metallogr. Microstruct. Anal. 4, 114–121 (2015). https://doi.org/10.1007/s13632-015-0192-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-015-0192-6