Abstract

The biorefinery concept associated with pulp mills, which already have the infrastructure and logistics to handle large volumes of forest biomass, appears to be one of the best options for the valorization of lignocellulosic biomass. This work investigates alternatives to the partial recovery of the hemicelluloses present in wood, by a green liquor extraction stage prior to kraft pulping of eucalyptus chips. The aim is to obtain an extract rich in hemicelluloses suitable for use as feedstock in the production of bioethanol without modifying the quality of the cellulose pulp produced. Different green liquor charges (0–6 %), several temperatures (100–165 °C), and reaction times (30–150 min) were studied with a constant liquor-to-wood ratio of 3.5. The best results are obtained at 155–160 °C for 150 min and working with a green liquor charge of 2 %. At these conditions, 2.9–3.2 % of xylose and 3.0–3.4 % of acetic acid are obtained from wood.

Similar content being viewed by others

References

Kamm B, Kamm M (2004) Principles of biorefineries. Appl Microbiol Biotechnol 64(2):137. doi:10.1007/s00253-003-1537-7

Wising BU, Stuart P (2006) Identifying the Canadian forest biorefinery. Pulp Pap Canada 107(6):25

Van Heiningen ARP (2006) Converting a kraft pulp mill into an integrated forest biorefinery. Pulp Pap Canada 107(6):38

Huang H-J, Ramaswamy S, Al-Dajani WW, Tschirner U (2010) Process modeling and analysis of pulp mill-based integrated biorefinery with hemicellulose pre-extraction for ethanol production: a comparative study. Bioresour Technol 101(2):624. doi:10.1016/j.biortech.2009.07.092

Van Heiningen ARP, Asuquo G, Dwyer B, Ronneberg D, Ramsey T (2010) Internal report: Integrated Forest Products Refinery (IFPR). Orono, Maine

Huang H-J, Ramaswamy S, Al-Dajani W, Tschirner U, Cairncross R (2009) Effect of biomass species and plant size on cellulosic ethanol: a comparative process and economic analysis. Biomass Bioenergy 33(2):234. doi:10.1016/j.biombioe.2008.05.007

Helmerius J, von Walter JV, Rova U, et al. (2010) Impact of hemicellulose pre-extraction for bioconversion on birch kraft pulp properties. Bioresour Technol 101(15):5996. doi:10.1016/j.biortech.2010.03.029

Garrote G, Domínguez H, Parajó JC (1999) Mild autohydrolysis : an environmentally friendly technology for xylooligosaccharide production from wood. J Chem Technol Biotechnol 74:1101. doi:10.1002/(SICI)1097-4660(199911)74:11<1101::AID-JCTB146>3.0.CO;2-M

Hosseinaei O, Wang S, Rials TG, Xing C, Zhang Y (2011) Effects of decreasing carbohydrate content on properties of wood strands. Cellulose 18(3):841. doi:10.1007/s10570-011-9519-x

Ban W, van Heiningen ARP (2011) Adsorption of hemicellulose extracts from hardwood onto cellulosic fibers—I. effects of adsorption and optimization factors. Cellul Chem Technol 45(1–2):57

Smook GA (2003) Handbook for pulp and paper technologists, Angus Wilde Publications, Inc.; 3rd edition, Vancouver

Huang H-JJ, Ramaswamy S, Tschirner UWW, Ramarao BVV (2008) A review of separation technologies in current and future biorefineries. Sep Purif Technol 62(1):1. doi:10.1016/j.seppur.2007.12.011

Carvalheiro F, Duarte LC, Gírio FM (2008) Hemicellulose biorefineries : a review on biomass pretreatments. J Sci Ind Res 67:849

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103. doi:10.1016/j.biortech.2015.10.009

Canettieri EV, Rocha GJM (2007) Evaluation of the kinetics of xylose formation from dilute sulfuric acid hydrolysis of forest residues of Eucalyptus grandis. Ind Eng Chem Res 46:1938. doi:10.1021/ie0607494

Garrote G, Falqué E, Domínguez H, Parajó JC (2007) Autohydrolysis of agricultural residues: study of reaction byproducts. Bioresour Technol 98(10):1951. doi:10.1016/j.biortech.2006.07.049

Romaní A, Garrote G, Alonso JL, Parajó JC (2010) Bioethanol production from hydrothermally pretreated Eucalyptus globulus wood. Bioresour Technol 101(22):8706. doi:10.1016/j.biortech.2010.06.093

Tunc MS, Chheda J, van der Heide E, Morris J, van Heiningen A (2014) Pretreatment of hardwood chips via autohydrolysis supported by acetic and formic acid. Holzforschung 68(4):401. doi:10.1515/hf-2013-0102

Pereira Ramos L (2003) The chemistry involved in the steam treatment of lignocellulosic materials. Quim Nov. 26(6):863. doi:10.1590/S0100-40422003000600015

Gírio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Łukasik R (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101(13):4775. doi:10.1016/j.biortech.2010.01.088

Iakovlev M, You X, van Heiningen A, Sixta H (2014) SO2–ethanol–water (SEW) fractionation process: production of dissolving pulp from spruce. Cellulose 21:1419. doi:10.1007/s10570-014-0202-x

Van Heiningen A, Genco J, Yoon S, et al. (2011) Integrated forest biorefineries: near-neutral process. In: Zhu J, Zhang X, Pan X (eds) Sustainable production of fuels, chemicals, and fibers from forest biomass. First. American Chemical Society, Washington, pp. 443–473

Testova L, Roselli A, Costabel L, Kovasin K, Tenkanen M, Sixta H (2014) Combined production of polymeric birch xylan and paper pulp by alkaline pre-extraction followed by alkaline cooking. Ind Eng Chem Res 53:8302. doi:10.1021/ie500694c

Al-dajani WW, Tschirner U, Jensen T (2009) Pre-extraction of hemicelluloses and subsequent kraft pulping, part II: acid- and autohydrolysis. Tappi Journal. September:30

Walton SL, Hutto D, Genco JM, Walsum GP, van Heiningen ARP (2010) Pre-extraction of hemicelluloses from hardwood chips using an alkaline wood pulping solution followed by kraft pulping of the extracted wood chips. Ind Eng Chem Res 49(24):12638–12645. doi:10.1021/ie100848p

Tunc MS, van Heiningen A (2009) Autohydrolysis of mixed southern hardwoods : effect of P-factor. Nord Pulp Pap Res J 24(1):42

Leschinsky M, Sixta H, Patt R (2009) Detailed mass balances of the autohydrolysis of Eucalyptus globulus at 170 °C. Bioresources 4(2):687

Martín-Sampedro R (2011) Integración del proceso kraft de obtención de pasta de celulosa en el esquema de una biorefinería. PhD. Dissertation, Universidad Complutense de Madrid

Rodriguez-Lopez J, Romani A, Gonzalez-Muñoz J, Garrote G, Parajo JC (2012) Extracting value-added products before pulping : hemicellulosic ethanol from Eucalyptus globulus wood. Holzforschung 66:591. doi:10.1515/hf-2011-0204

Leschinsky M, Weber HK, Patt R, Sixta H (2009) Formation of insoluble components during autohydrolysis of Eucalyptus globulus. Lenzinger Berichte 87:16

Al-dajani WW, Tschirner U (2008) Alkaline extraction of hemicelluloses from aspen chips and its impact on subsequent kraft pulping. TAPPI J 7(6):3

Bracelpa, “Brazilian pulp production evolution,” 2015. [Online]. Available: http://bracelpa.org.br/bra2/?q=en/node/240. [Accessed: 15-Feb-2016]

ODEPA, “Produccion de la industria forestal,” 2015. [Online]. Available: http://www.odepa.cl/produccion-de-la-industria-forestal-4/. [Accessed: 15-Feb-2016]

MGAP-DGF, “Estadísticas y Mercado,” 2015. [Online]. Available: http://www.mgap.gub.uy/portal/page.aspx?2,dgf,dgf-estadisticas-y-mercado,O,es,0,. [Accessed: 15-Feb-2016]

Sixta H (2006) Handbook of pulp, First edn. WILEY-VCH Verlag GmbH &Co. KGaA, Weinheim, pp. 188–191

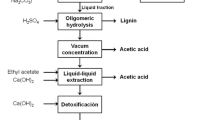

Guigou M, Cebreiros F, Ferrari MD, Cabrera MN, Lareo C (2016) Bioethanol production from Eucalyptus grandis hemicellulose hydrolyzate recovered before kraft pulping using an integrated forest bioerfinery concept. in 38th Symposium on Biotechnology for Fuels and Chemicals. Paper 31744

Alen R, Hartus T (1988) UV spectrophotometric determination of lignin from alkaline pulping liquors cellulose Chem. Technol. 22(6):613

Luo J, Genco JM, Zou H (2012) Extraction of hardowood biomass using dilute alkali. TAPPI J 11(6):19

Mao H, Genco JM, van Heiningen A, Pendse H (2009) Kraft mill biorefinery to produce acetic acid and ethanol: technical economic analysis. Bioresources 5(2):525

Acknowledgments

We would like to express our gratitude to the Agencia Nacional de Investigación e Innovación (ANII-FSE) for the financial support to do this work, to UPM Fray Bentos personnel for providing the industrial chips, and to the Department of Forest Projects at Laboratorio Tecnológico del Uruguay (LATU) for their kind collaboration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cabrera, M.N., Arrosbide, M.F., Franzoni, P. et al. Integrated forest biorefineries: green liquor extraction in eucalyptus wood prior to kraft pulping. Biomass Conv. Bioref. 6, 465–474 (2016). https://doi.org/10.1007/s13399-016-0203-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-016-0203-0