Abstract

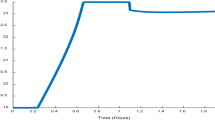

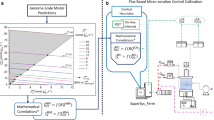

This paper investigates the dynamic performance of bioethanol production process. The process is simulated by an experimentally validated model in the literature. The analysis of the open loop system revealed that the maximum productivity occurred at a moderate ethanol production and substrate consumption. Improvement of the process productivity beyond the maximum value is sought through periodic input forcing. Rectangular pulses were used to simulate the periodic input function because they are suitable for discrete control systems. The parameters of the rectangular pulse such as period, amplitude and central value were designed using numerical optimization. Forcing the optimized cycling input into the process revealed substantial increment of the ethanol production and substrate consumption. However, the obtained enhancement of productivity is considered marginal when compared to the existing maximum productivity. On the other hand, enrichment of productivity is considered reasonable when compared to that obtained when the process operates at steady state using the average value for the input periodic function.

Similar content being viewed by others

Abbreviations

- D, D i :

-

Dilution rate and its initial value (1/h)

- F :

-

Flow rate (l/h)

- k :

-

Sampling instant

- K 1, K 2 :

-

Saturation constants (g/l)

- k c , k i :

-

PI controller settings, i.e. gain and gain divided by integral time

- k c0 :

-

Initial value for controller gain

- k p , k p0 :

-

Process gain, initial process gain

- m p :

-

Maintenance factor of ethanol (1/h), 2.6

- m s :

-

Maintenance factor for substrate (1/h)

- npa:

-

Negative pulse amplitude

- ppa:

-

Positive pulse amplitude

- P c :

-

Limiting ethanol concentration for viable cells (g/l)

- P′ c :

-

Limiting ethanol concentration for non-viable cells (g/l)

- P r :

-

Productivity of ethanol (g/l h)

- P w :

-

Pulse width

- S, S 0 :

-

Substrate, feed substrate concentration (g/l)

- u :

-

Input variable

- V :

-

Reactor volume (l)

- t :

-

Time

- w i :

-

Weighting factor in the optimization problem

- x :

-

State vector

- X v :

-

Viable cell concentration (g/l)

- X nv :

-

Non-viable cell concentration (g/l)

- X d :

-

Dead cells (g/l)

- Y :

-

Process output

- Y x/p :

-

Yield coefficient in conversion from biomass to ethanol (–)

- Y x/s :

-

Yield coefficient in conversion from biomass to substrate (–)

- μ d :

-

Growth rate of dead cells (1/h)

- μ max :

-

Maximum growth rate of viable cells (1/h)

- μ′ max :

-

Maximum growth rate of non-viable cells (1/h)

- μ nv :

-

Growth rate for non-viable cells (1/h)

- μ V :

-

Growth rate of dead cells (1/h)

- L:

-

Lower value

- U:

-

Upper value

References

Astudillo, I.C.P.; Alzate, C.A.C.: Importance of stability study of continuous systems for ethanol production, J. Biotechnol. (2012) (in press)

Borzani W: Variation of ethanol yield during oscillatory concentrations changes in undisturbed continuous ethanol fermentation of sugar-cane blackstrap molasses. World J. Microbiol. Biotechnol. 17, 253–258 (2001)

Garhyan P., Elnashaie S.S.E.H., Al-Haddad S.M., Ibrahim G., Elshishini S.S: Exploration and exploitation of bifurcation/chaotic behavior of a continuous fermentor for the production of ethanol. Chem. Eng. Sci. 58, 1479–1496 (2003)

Garhyan P., Elnashaie S.S.E.H: Utilization of mathematical models to investigate the bifurcation and chaotic behavior of ethanol fermentors. Math. Comput. Model. 39, 381–427 (2004)

Garhyan P., Elnashaie S.S.E.H: Static/dynamic bifurcation and chaotic behavior of an ethanol fermentor. Ind. Eng. Chem. Res. 43, 1260–1273 (2004)

Abulesz E.M., Lyberatos G: Periodic optimization of continuous microbial growth processes. Biotechnol. Bioeng. 29, 1059–1065 (1987)

Kumar G.P., Subrahmanya I.V.K., Chidambaram M: Periodic operation of a bioreactor with input multiplicities. Can. J. of Chem. Eng. 71, 766–770 (1993)

Parulekar S: Analysis of forced periodic operations of continuous bio-processes—Single input variations. Chem. Eng. Sci. 53, 2481–2502 (1998)

Parulekar S: Analysis of forced periodic operations of continuous bio-processes—Multiple input variations. Chem. Eng. Sci. 55, 513–533 (2000)

Pavlou S., Kevrekidis I.G., Lyberatos G: On the coexistence of competing microbial species in a chemostat under cycling. Biotech. Bioeng. 35, 224–232 (1990)

Ruan L., Chen X.D: Comparison of several periodic operations of a continuous fermentation process. Biotechnol. Prog. 12, 286–288 (1996)

Stephens, M.L.; Christensen, C.; Lyberatos, G.: Plasmid stabilization of an Escherichia coli culture through cycling. Biotechnol. Prog. 8, 1–4 (1992)

Ajbar , Ajbar : On the improvement of performance of bioreactors through periodic forcing. Comput. Chem. Eng. 35(6), 1164–1170 (2011)

Al-haj A., Ali E., Ajbar A., Alhumaizi K: Study of cyclic operation of RO desalination process. Can. J. Chem. Eng. 89(2), 299–303 (2011)

Al-haj A., Ali E: Broadening the polyethylene molecular weight distribution by periodic hydrogen feed rates. Macromol. React. Eng. 5, 85–95 (2011)

Jarzebski A.B: Modeling of oscillatory behavior in continuous ethanol fermentation. Biotechnol. Lett. 14, 137–142 (1992)

Perego, P.; Dias, J.M.C.D.; Koshimizu, L.H.; Cruz, M.R.D.; Borzani, W.; Vairo, M.L.R.: Influence of temperature, dilution rate and sugar concentration on the establishment of steady-state in continuous ethanol fermentation of molasses. Biomass 6, 247–256 (1985)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, E., Ajbar, A. & AlHumaizi, K. Enhanced Ethanol Reactor Operation Through Periodic Forcing of the Feed Rate. Arab J Sci Eng 38, 741–750 (2013). https://doi.org/10.1007/s13369-012-0526-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-012-0526-5