Abstract

Waste management of powdered activated carbon from cyclone of some sugar factories was used for decolorization of sugar mud juice (SMJ) in this study. The presence of powdered activated carbon waste (PACW) was admitted again for their use in SMJ decolorization. The determined specific surface area are typically SBET = 613.887 m2/g and the pore distribution lies in mesoporous domain. Color removal (CR%) and decolorization capacity (DC) of the characterized PACW are similar to those of decolorants used at this time for sugar refining. The CR% with PACW reached 81.03% at pH7.0 and dosed in the amount 0.5 g/50 ml of SMJ. There are two acceptable mechanisms illustrates the attachments between phenols and carboxylate ions. In this paper, we put a simple and rapid dark liquid decolorization by controlling rejected carbon waste, which will be useful for treatment of dark liquid sugar.

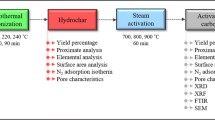

Graphical abstract

Schematic representation of the simple pathway of SMJ decolorization

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Carbon decolorization still extensively applied in the field of food production such as sugar refining to remove color precursors from different types of juice (Bourzutsckky 2005; Chou 2010). The reactions that take place during the production are the main reason for such colored compounds in the sugar manufacturing. Furthermore, it is not possible to determine the chemical structure of the relevant coloring compounds and difficult to control in many cases. Melanin, melanoidins and caramel types are the most proper colored components formed during sugar carbonation process (Singh et al. 2011). There are twenty-one phenolic compounds in the cane sugar plantation according to Farber and Carpenter, who also reported, four colored types in refined sugar, and nearly ten in raw sugar (Farber and Carpenter 1971). Moreover, the red-colored quinones, indole and melanin derivatives, result from the oxidation of phenolic compounds. Therefore, we can conclude that the polyphenols are responsible for color formation in sugar processing (Gross and Coombs 1976). With increasing energy costs related to the sugar production and environmental impacts, it is highly important to re-estimate the old decolorization technologies with respect to their virtues. These techniques include affination, carbonation or phosphatation that are classified as a primary decolorization stage, and secondary expensive decolorization technique-based ion-exchange resins (Singh et al. 2011). Moreover, treatment with hydrogen peroxide or sulfur dioxide have some toxic effect overdose; therefore, to produce high juice clarity and good-quality white sugar products, a new cost-reduction material used for treatment of juice like powdered activated carbon is developed (van der Poel et al. 1998).

Existence of large specific surface area (up to 4000 m2/g) makes powdered activated carbon (PAC) a superior food decolorant and efficient adsorbent for the removal of contaminants from wastewater streams (Gupta et al. 2009; Gupta and Rastogi 2009; Rao et al. 2010; Lu et al. 2011).

Powdered activated carbon waste (PACW) as a secondary product in some sugar factories attributed to the hydrothermal activation of the main granulated active carbon (GAC) after burning process in the kiln. By such pretreatment, a wet PACW biomass is dehydrated and used again. As requirements for hygiene and safety in sugar decolorization process, the decolorizing material should possess large surface area, good porosity and pH sensitivity for sugar colorants such as flavonoids and phenolic structures (Singh et al. 2012; Liu et al. 2012). Moreover, during processing, especially after polishing filtration, the sugar mud juice (SMJ) was obtained which is a very complicated sludge (high color, bad odor, high viscosity, high brix, etc.), and this is our noble target for decreasing the color as much as possible. There are physical and chemical treatments for dealing with PAC, but the thermal and chemical activation methods are the most predominant techniques for regeneration of exhausted PAC (Gupta et al. 2009; Lu et al. 2011; Guo et al. 2011; Lim and Okada 2005; Simaratanamongkol and Thiravetyan 2010). Thus, the temperature was raised up to 600 °C in the thermal activation process (Martin and Ng 1984). Color removal from SMJ considered new tools and new idea to decrease color of non-sugar compounds such as betaine and phenolic substances. In this respect, a practical and economic way to add value to the waste carbon in sugar factory is deeply required.

In the present paper, we intend to find out an alternative, effective cost-reduction process to get rid of the unacceptable sugar defects, such as color and turbidity, from highly concentrated sugar mud tank (black mud liquor). In addition, the use of PACW is determined and it is compared with reference commercial carbon via adsorption technique for the SMJ process decolorization, and the surface parameters of the used PACW are measured according to IUPAC system.

Materials and methods

Materials

The sugar mud juice (SMJ) dark liquid (Fig. 1) was a generous gift from the United Sugar Company, Saudi Arabia, Jeddah port. Series of samples of the SMJ were collected at the point after polish filters empty slurry. The samples were freshly taken and stored in the refrigerator prior to use. The physical properties of the SMJ determined according to International Commission for Uniform Methods of Sugar Analysis (ICUMSA) (Lopez et al. 2003) are given in Table 1. The Carbo UA (CUA), DCL 320 (reference carbon), was purchased from Sigma. PACW was collected from cyclone outlet ball valve (Fig. 2). Filter aid, commercial strong amorphous silica FW60, was a gift from Spain. All other reagents were used as received.

Methods

Decolorization of SMJ by continuous process

To detect the analytical methods towards SMJ decolor performances, initially batch-technique adsorption experiments assisted. The SMJ solution was filtered through 0.45-µm filter paper to remove any heavy suspended particles; for the turbid solution pH was adjusted to 7.0 using 3-(N-morpholino) propane sulfonic acid (MOPS) buffer. A known mass (0.5 g) of CUA, PACW and FW60 adsorbents were added to three solutions in three separate closed Pyrex glass bottles. The different bottles were kept in a thermo-stated water bath at constant temperature and regular constant shaking until equilibrium was attained. Then the solutions were filtered again and at wavelength 420 nm the absorbance was determined using a UV–visible spectrophotometer. The absorbance readings were converted into color in ICUMSA units (IU) using the equation:

where Abs is the equal absorbance at 420 nm of the test sample, b is the cell length (cm) and c is the sugar concentration (g sugar/ml). The color removal (CR%) and decolorization capacity (DC) are expressed as follows:

where IUi, IUf and m are the ICUMSA color of the initial, final (treated) solution and weight of dry decolorant (g), respectively.

Measurements of iodine and molasses number

A stock solution from 2.7 g I2 and 4.1 g KI in 1L of solution was prepared, 50 ml from this solution was added to 0.5 g PACW plus CUA in 10 mL of 5% HCl solution. After stirring for 15 min, the sample was filtered and the CR% was recorded for the sample and the blank filtrates based on the volumes of 0.1 M sodium thiosulphate required (using starch as the indicator) (Anon 1994). For the molasses number (MN) test, 10 g of dark sugar beet molasses and 15 g of Na2HPO4 were dissolved in a bottle of 500 mL water and sufficient amount of H3PO4 was added to adjust the pH around 6.5; the above mixture was diluted to 1 L and filtered using 5 gm of light filter aid (silica type). In another bottle, 50 mL of this solution was added to 0.5 g of each decolorant with vigorous stirring until the solution was brought to boil. The CR% for the sample and the blank was determined spectrophotometrically.

Characterization and test methods

FT-IR spectrometer (Nicolet, NEXUS-670) was used to detect the functional groups of the PACW (before and after decolorization), between 4000 and 500 cm−1 using KBr pellets. The SBET and related parameters based on isotherms of adsorption–desorption isotherms was measured at 77 K using (Nova 3200 USA) Micrometrics gas adsorption analyzer. The surface texture was studied by SEM (S-3400 N II, Hitachi, Japan) at two different magnifications; the sample was coated with gold prior to evaluation. Absorbance was measured using a double-beam UV spectrophotometer (Shimadzu UV-1208 model).

Results and discussion

Characterization tools of CUA, PACW and FW60

SEM morphology

Figure 3 illustrates the surface morphology and textures of decolorants at 20 and 100µ magnification. Figure 3a shows that CUA as reference is very ordered, regular and has multi-porous-like layers; on the other hand, in Fig. 3b, PACW shows resemblance to the reference CUA. The surface texture resembles amorphous-like sheets and multi-branch layers due to high white magnesium oxide content (Hassler 1963). In case of FW60 (Fig. 3c), ultimately different structure can be viewed due to silica origin marine source and the surface texture of FW60 has deep pores and rings, and the crystalline pattern has no meaning. All these textural features help in sugar color adsorption due to the possibility of disaccharide molecules to take up these spaces (Hao et al. 2014).

BET characterization

According to IUPAC, there are three pore size categories: macropores (> 50 nm), mesopores (2–50 nm) and micropores (< 2 nm) (Cardoso et al. 2012). Figure 4a depicts the isotherms in the form of type II isotherm function (Ewecharoen et al. 2009). In addition, the adsorption increases sharply in the initial low relative pressure indicating the existence of a large amount of small pores on PACW structure. There is a small inflection in the region p/p0 > 0.3, and at a high relative pressure, p/p0 > 0.9, rises rapidly. These types of isotherms were characterized for adsorption onto open surfaces with multilayer formation (Lowell et al. 2004). Figure 4b calculates the pore size distribution using BJH method. The plot shows the PACW has internal micropore radius Dv(r) of 3.452 nm and total pore volume with radius smaller than 224.9 Å, harmonious with the highest specific surface area 613.887 m2/g compared with the BET of other carbon decolorants as shown in Fig. 5.

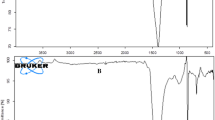

FT-IR illustration

Figure 6 shows the FT-IR of PACW before and after color adsorption behavior. The peak at 2856 cm−1 featured for symmetric or asymmetric stretching –CH in aliphatic series. By perusing literatures (Rao et al. 2010; Lu et al. 2011; Singh et al. 2012; Hao et al. 2014; Cardoso et al. 2012; Ewecharoen et al. 2009; Lowell et al. 2004; da Cunha Gonçalves et al. 2016), all spectra show broad absorption band around 3250–3700 cm−1, which belongs to the (–OH) stretching vibration in carboxyl, phenols, alcohols, and in the absorbed water from PACW. Si–O–Si network vibrations were identified at 1041.3 and 876.4 cm−1. At 1636 cm−1 strong peak related to the stretching vibration of C–O carboxyl or carbonyl groups. The aromatic ring that contains the skeletal units of C–C vibration appeared at 1455 cm−1 (Danish et al. 2014; Shoueir et al. 2016). Apparently, after decolorization, several bands were shifted, which confirmed the presence of oxides in PACW.

Clarification of SMJ according to IN and MN tests

IN largely determines the porosity in decolorants of active carbons. For high specific surface area carbons (> 1000 m2 g−1), the IN is a relative indicator of BET surface area measurements, whilst for low specific surface area IN will devolve away. Figure 7 shows the IN and MN comparison with the PACW and CUA (referenced carbon). As mentioned before, the IN correlated to the surface area which explains the differences in IN between adsorbents indicate higher surface area and decreased pore volume to attain micropore configuration (da Cunha Gonçalves et al. 2016). In addition, figure illustrates that referenced CUA has a very high MN, whereas PACW showed relatively lower MN color removal and the presence of micropore radius and total pore volume with radius smaller than 224.9 Å are responsible for this differences. The high specific surface area 613.887 m2/g helping access and facile penetration of any colored organic compounds into the interior surface of PACW (Danish et al. 2014). Comparing the decolorization unit of mud syrup with those of IN and MN with two samples concluded that the presence of small and large pores in the configuration structure led to excellent pore size distribution and adsorption of poly-dispersed colorants. The macropore network causes fast diffusion of color structure than the smaller pores, where they are adsorbed (Shoueir et al. 2016).

Clarification of SMJ by adding FW60 to PACW

It was prone to use only PACW decolorants but also FW60 was added physically in the second stage to enhance CR%. Table 2 shows the mother mud juice after filtration and still contains a large amount of impurities, such as colloids, suspended solids, reducing sugar and others. In this respect, adding FW60 adds value to PACW (Table 2) unless the color enhanced and there was no detected difference in ash of SMJ. Results of SMJ quality after addition of different doses from FW60 to PACW are presented in Fig. 8. The treated SMJ with higher doses of FW60 had slightly increased CR% until certain dose (0.5gFW60/0.5gPACW/50 mlSMJ) at the optimal clearance CR% was viewed. FW60 was used in sugar manufacture to underlay the filter for more filtration process. Adsorption of colorants and organic molecules like protein on FW60/PACW reduced SMJ color, turbidity and this is due to the greater adsorption surface (Pelekani and Snoeyink 2000).

Determination of CR% under static motion

The static adsorption of color was used to determine the performances of the decolorant materials. Typically, 50 ml from SMJ with pH 7.0 ± 0.1 using MOPS buffer was placed in the beaker flasks with the soaking of 0.5 g of CUA, PACW, FW60, for 2 h with vigorous shaking at 30° C. The initial and final absorbencies of decolorants are calculated according to equations presented Sect. 2.2.1. Table 2 tabulates the results, which indicates that the CR% of the PACW was up to 81.03%. The results give reflection on both quality assurance and control that give PACW the capability to remove both color and turbidity. Moreover, the turbidity is unacceptable at all for white sugar product and an important criterion for deciding the quality of a food product. Also, the turbidity was always tiny found but improved in the final decolorized solution (Jahed et al. 2014).

Effect of time on clarification

The experimental data behavior for the adsorption of turbid mud juice is embraced in this study as a function of time. Figure 9 shows increasing time gives adsorbent the ability to adsorb organic substances; PACW amongst kith is efficient with CR% reaching 90.4% at 30 min equilibrium. During thermal activation, the high specific area increased which gives the hydrophobicity features for PACW. Indeed, the PACW superior food decolorant due to neutral pH, low conductivity, low turbidity and high surface area which is directly proportional to specific surface area (Gupta and Rastogi 2009; Frank et al. 1989; Hao et al. 2014).

Environmental impacts

PACW is considered a waste and reuse it again decouple their importancy. The removal efficiency of PACW due to thermal activation in the kiln that carbonization and activation are carried out simultaneously, so in this case we can consider PACW manufacturing is a cheap and eco-friendly carbon source. Although, many of other commercial materials are not environmentally green. As example, animal origin carbon source is becoming of concern due to release of segments with pathogenic effect (El-Hendawy et al. 2008). These treatments are wearisome, high cost, not safe for the environment and time consuming. Ion exchange is an expensive process due to the high costs and severity of regeneration after treatment and the maximum color dealing with no more than 1500 IU (Guimaraes et al. 1996).

Decolorization mechanism

Most of the postulated decolorization mechanism is based on the nature of surface texture functionality and the surface charge affinity. Thus, our supposal is based on the following items:

(1) If the structure of phenolic substances shows partially negatively charged carboxylate ion, it can interact with positively charged surface of PACW by electrostatic attraction forces:

The spotted line represents the electrostatic attraction, (2) the partially negative-charged carboxylate ion can provide H.b sites with the PACW+ surfaces which enhances the adsorption capability of phenolic acids on the surface (Rao et al. 2010; Drago et al. 1964; Mattson et al. 1969).

where the dotted bond represents H.b. Under normal liming conditions, polyphenols are not sufficiently ionized, and at neutral pH 7.0, the polyphenols existing in SMJ solution will be also in neutral form, which preferred being adsorbed onto the PACW surfaces. The phenolic adsorption may be due to the interaction between the ring of phenols and the aromatic species of the ash (Salame and Bandosz 2003).

Comparison of PACW with other decolorizing agents

The maximum CR% using raw sugar sample (970 IU) as an adsorbate solution was used as model for comparison between PACW, CUA, dowex 2, Accrual and Indion 830-s. The result of this study is reported in Table 3, and it is clear that PACW has high CR% fitted with standard decolorizing structures. The performance of any sugar decolorant systematically depends on its CR%; however, CR% alone is not sufficient due to the mother load color not included. To determine the performance of the CR%, process technology should be conjugated with color feeding. Table 4 illustrates that load color index in the case of present process is very high (3700 IU) as compared to the standard procedures. The adsorption capacities of the adsorbent are comparatively higher than the other different carbon or ion exchanger-based decolorants. Our results reveal the potential of these dynamics to be an effective waste adsorbent for removing organic color from aqua system.

Conclusions

Powdered activated carbon waste (PACW) has tremendous activity for the decolorization of sugar mud juice in the sugar refining. The high specific surface area of PACW enhances adsorption and color removal. PACW was found to be comparable to those of the adsorbents actually used for sugar remediation. In addition, the surface morphology of PACW much similar to CUA reference carbon, the exactly CR% was 81.20% which able to remove most of phenolic compounds and the mechanism was explained on the basis that the nature of surface texture functionality and the surface charge affinity.

References

Anon (1994) ICUMSA colour determination method, method 2. International Commission for Uniform Methods of Sugar Analysis

Bourzutsckky HCC (2005) Color formation and removal option for the sugar and sugar refining industries: a review. Zuckerindustrie 130:470

Cardoso NF, Lima EC, Royer B, Bach MV, Dotto GL, Pinto LAA, Calvete T (2012) Comparison of Spirulina platensis microalgae and commercial activated carbon as adsorbents for the removal of reactive red 120 dye from aqueous effluents. J Hazard Mater 241:146

C.C. Chou (2010) Pros and cons of various decolorization processes for the production of refined sugar. Presented at the Sugar Industry Technologists (SIT), Annual Meeting, Savannah, GA, 16–19 May 2010. Sugar Industry Technologists, Inc. of New York, Paper 992

da Cunha Gonçalves G, Pereira NC, Veit MT (2016) Production of bio-oil and activated carbon from sugarcane bagasse and molasses. Biomass Bioenergy 85:178

Danish M, Hashim R, Ibrahim MNM, Sulaiman O (2014) Optimized preparation for large surface area activated carbon from date (Phoenix dactylifera L.) stone biomass. Biomass Bioenergy 61:167

Drago RS, Niedzielski RJ, Middaugh RL (1964) Donor properties of some sulfur compounds. J Am Chem Soc 45:1694

El-Hendawy ANA, Alexander AJ, Andrews RJ, Forrest G (2008) Effects of activation schemes on porous, surface and thermal properties of activated carbons prepared from cotton stalks. J Anal Appl Pyrolysis 82:272

Ewecharoen A, Thiravetyan P, Wendel E, Bertagnolli H (2009) Nickel adsorption by sodium polyacrylate-grafted activated carbon. J Hazard Mater 171:335

Farber L, Carpenter FG (1971) Identification of cane pigments that persists into refined sugar. Int Sugar J 73:99

Frank D, Metcalfe LD, Park JY (1989) Decolorization of aqueous saccharide solutions and sorbents therefore. U.S. Patent No. 4, 806,520, 7

Gergova K, Petrov N, Eser S (1993) A comparison of adsorption characteristics of various activated carbons. J Chem Technol Biotechnol 56:77

Gross D, Coombs J (1976) Enzymatic colour formation in beet and cane juices. Int Sugar J 58:69

Guimaraes C, Bento LSM, Mota MA (1996) Study of sugar colorants through ion exchange and salt regeneration. Int Sugar J 98:584

Guo D, Shi Q, He B, Yuan X (2011) Different solvents for the regeneration of the exhausted activated carbon used in the treatment of coking wastewater. J Hazard Mater 186:1788

Gupta VK, Rastogi A (2009) Biosorption of hexavalent chromium by raw and acid treated green alga Oedogonium hatei from aqueous solution. J Hazard Mater 163:396

Gupta VK, Carrott PJM, Ribeiros Carrott MML, Suhas (2009) Low cost adsorbent: growing approach to wastewater treatment—a review. Crit Rev Environ Sci Technol 39:783

Hao W, Bjorkman E, Yun Y, Lilliestrale M, Hedin N (2014a) Iron oxide nanoparticles embedded in activated carbons prepared from hydrothermally treated waste biomass. ChemSusChem 7:875

Hao W, Bjorkman E, Lilliestråle M, Hedin N (2014b) Activated carbons for water treatment prepared by phosphoric acid activation of hydrothermally treated beer waste. Ind Eng Chem Res 53:15389

Hassler JW (1963) Activated carbon. Chemical Publishing Co, New York, pp 345–364

Jahed E, Khodaparast MHH, Khaneghah AM (2014) Bentonite, temperature and pH effects on purification indexes of raw sugar beet juice to production of inverted liquid sugar. Appl Clay Sci 102:155

Lim JL, Okada M (2005) Regeneration of granular activated carbon using ultrasound. Ultrason Sonochem 12:277

Liu X, Lin R, Chen S, Ma N, Huang Y (2012) Preparation of a bagasse-based anion exchange fiber for sugar decolorization. J Appl Polym Sci 126:E345

Lopez F, Medina F, Prodanov M, Güell C (2003) Oxidation of activated carbon: application to vinegar decolorization. J Colloid Interface Sci 257:173

Lowell S, Shields JE, Thomas MA, Thommes M (2004) characterization of porous solids and powders: surface area, pore size, and density. Academic press, New York

Lu PJ, Lin HC, Yu WT, Chern JM (2011) Chemical regeneration of activated carbon used for dye adsorption. J Taiwan Inst Chem Eng 42:305

Martin RJ, Ng WJ (1984) Chemical regeneration of exhausted activated carbon—I. Water Res 18:59

Mattson JS, Mark HB, Malbin MD, Weber WJ, Crittenden JC (1969) Surface chemistry of active carbon: specific adsorption of phenols. J Colloid Interface Sci 31:116

Pelekani C, Snoeyink VL (2000) Competitive adsorption between atrazine and methylene blue on activated carbon: the importance of pore size distribution. Carbon 38:1423

Rao RAK, Khan MA, Jeon BH (2010) Utilization of carbon derived from mustard oil cake (CMOC) for the removal of bivalent metal ions: effect of anionic surfactant on the removal and recovery. J Hazard Mater 173:273

Salame II, Bandosz TJ (2003) Role of surface chemistry in adsorption of phenol on activated carbons. J Colloid Interface Sci 264:307

Shoueir KR, Sarhan AA, Atta AM, Akl MA (2016) Macrogel and nanogel networks based on crosslinked poly (vinyl alcohol) for adsorption of methylene blue from aqua system. Environ. Nanotech. Mont. Manage. 5:62

Simaratanamongkol A, Thiravetyan P (2010) Decolorization of melanoidin by activated carbon obtained from bagasse bottom ash. J Food Eng 96:14

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl Chem 57:603

Singh K, Bharose R, Singh VK, Verma SK (2011) Sugar decolorization through selective adsorption onto functionalized accurel hydrophobic polymeric support. Ind Eng Chem Res 50:10074

Singh K, Bharose R, Verma SK, Singh VK (2012) Potential of powdered activated mustard cake for decolorising raw sugar. J Sci Food Agric 93:157

van der Poel PW, Schiweck H, Schwartz T (1998) Sugar Technology: beet and cane sugar manufacture. Verlag Dr. Albert Bartens KG, Berlin, p 516

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest for this paper.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Aljohani, H., Ahmed, Y., El-Shafey, O. et al. Decolorization of turbid sugar juice from sugar factory using waste powdered carbon. Appl Water Sci 8, 48 (2018). https://doi.org/10.1007/s13201-018-0681-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0681-2