Abstract

The present work aims at evaluation of the potential of cyanobacterial biomass to remove Cu(II) from simulated wastewater. Both dried and carbonized forms of Lyngbya majuscula, a cyanobacterial strain, have been used for such purpose. The influences of different experimental parameters viz., initial Cu(II) concentration, solution pH and adsorbent dose have been examined on sorption of Cu(II). Kinetic and equilibrium studies on Cu(II) removal from simulated wastewater have been done using both dried and carbonized biomass individually. Pseudo-second-order model and Langmuir isotherm have been found to fit most satisfactorily to the kinetic and equilibrium data, respectively. Maximum 87.99 and 99.15 % of Cu(II) removal have been achieved with initial Cu(II) concentration of 10 and 25 mg/L for dried and carbonized algae, respectively, at an adsorbent dose of 10 g/L for 20 min of contact time and optimum pH 6. To optimize the removal process, Response Surface Methodology has been employed using both the dried and carbonized biomass. Removal with initial Cu(II) concentration of 20 mg/L, with 0.25 g adsorbent dose in 50 mL solution at pH 6 has been found to be optimum with both the adsorbents. This is the first ever attempt to make a comparative study on Cu(II) removal using both dried algal biomass and its activated carbon. Furthermore, regeneration of matrix was attempted and more than 70% and 80% of the adsorbent has been regenerated successfully in the case of dried and carbonized biomass respectively upto the 3rd cycle of regeneration study.

Similar content being viewed by others

Introduction

Heavy metal pollution of aquatic system is a serious environmental problem, resulting from rapid industrialization. Due to their non-biodegradable and recalcitrant nature, they accumulate in the environment causing a serious threat to human health and ecological systems (Papageorgiou et al. 2008). As per the list published by United States Environmental Protection Agency (USEPA) in 1978, the most hazardous metals listed are antimony, arsenic, beryllium, cadmium, copper, lead, mercury, nickel, selenium, silver, thallium and zinc. According to USEPA, maximum permissible limit of copper in drinking water and industrial wastewater is 1.0 and 3.0 mg/L, respectively. Though copper, a heavy metal, is essential in minute amount (3 mg/day) for different biochemical pathways in human body, it becomes toxic when its concentration in drinking water exceeds the permissible limit. Copper is found in effluent coming from different industries such as electroplating, coal, tanning, smelting, copper wire mills, insecticides, fungicides, etc. The presence of Cu(II) ions above permissible limit is extremely toxic to living organisms. It is usually known to be deposited in liver, pancreas, brain and may produce gastrointestinal catarrh (Gupta et al. 2006). Conventional methods such as chemical precipitation, ion exchange, chemical oxidation and electrochemical treatment have been used to reduce heavy metals from polluted water but these are expensive, less effective, inefficient at low metal concentration i.e., below 100 mg/L and produce toxic sludge (Yilmazer and Saracoglu 2009).

Adsorption process is recognized as an effective and economic method for the abatement of heavy metals from wastewater (Fu and Wang 2011). Using microorganisms as sorbent is a new and very promising technology for wastewater treatment. The major advantages of biosorption over conventional methods are low cost, minimization of sludge, highly efficient at low metal ion concentration and regeneration of biosorbent. Biosorption occurs by physicochemical interaction between the cell surface and metal ions and hence reported as metabolically independent mechanism while bioaccumulation is metabolically dependent mechanism (Flouty and Estephane 2012). Bacteria, fungi, yeast and algae are potential metal biosorbent and among these the cyanobacterial populations have been found as more promising due to their simple nutrient requirements, larger biomass production and generally non-toxic and eco-friendly nature (Kiran and Kaushik 2008). Phycoremediation of heavy metals is an emerging technology in which macroalgae or microalgae are used to remove or transform the pollutants. Algae have high metal binding capabilities due to the presence of negative charges on the surface of their cell walls (Pittman et al. 2011). Dried algal biomass and its activated carbon are used for passive uptake of heavy metals while living cells take part actively in biosorption and bioaccumulation processes. As maintenance of living alga at higher metal ion concentration is a challenging job, the present study deals with biosorption using dried and carbonized algal biomass. The efficiency of this process is dependent on different parameters viz., metal ion concentration, adsorbent dose, adsorbent size and solution pH (Das et al. 2008). Hence, optimization of these process parameters is mandatory from proper bioreactor operation perspectives. The conventional technique for the optimization of a multivariable system usually defines one factor at a time (Sahu et al. 2009). Response Surface Methodology (RSM) can be used to overcome the problems associated with the conventional method for optimization of removal of Cu(II). RSM is a collection of mathematical and statistical techniques useful for developing, improving and optimizing processes (Silva et al. 2004; Ravikumar et al. 2006, 2007; Karacan et al. 2007). Though a number of studies have been done to optimize chemical processes using RSM, its application in the field of phycoremediation using two different forms of algae (dried and carbonized) is probably a novel approach.

East Kolkata Wetland (EKW) is a biodiversity rich region (Kundu et al. 2008). Different industries like paints, electroplating, and battery discharge their waste into the ponds of wetland. Wastes of these industries act as source of different metals like chromium, copper, etc. and phytoplankton found in this wetland area are highly resistant to these metals. In the present work, the cyanobacterium strain Lyngbya majuscula, collected from EKW site, has been used for sorption study of Cu(II) from its aqueous solution. It is a filamentous non-heterocystous cyanobacteria belonging to the family Oscillatoriaceae. Though few works have been done either with dried algal biomass or carbonized algal biomass, the usage of both dried and carbonized form of L. majuscula for abatement of heavy metal from wastewater is extremely terse. Therefore, in the present study, the efficacy of both dried and carbonized biomass of L. majuscula in removal of Cu(II) from simulated wastewater is assessed.

Materials and methods

All the experiments were repeated thrice and the arithmetic mean value has been reported. All the chemicals used were of AR grade unless otherwise stated.

Collection and preparation of test alga

Dried biomass

Fresh algal biomass was collected from East Kolkata Wetland, Kolkata (EKW), West Bengal (Latitude: 20° 25′N–22° 35′N Longitude: 88° 20′E–88° 35′E). The East Kolkata Wetland is a biodiversity rich region and listed under the Ramsar Bureau established under the article 8 of Ramsar Convention (Kundu et al. 2008). Collected strain was identified as cyanobacterial strain of L. majuscula from Botanical Survey of India, Ministry of Environment and Forests, Kolkata, India. Before use, it was washed in running tap water and then with distilled water to remove dirt and then dried at 70 °C in hot air oven for 24 h. The dried biomass was ground and sieved to select the desired particle size to use as biosorbent.

Activated carbon

Optimization of carbonization condition and preparation of carbonized algal biomass

Experimental The dried biomass was ground and sieved to select the particle size of ~300 µm for carbonization. Ortho-phosphoric acid (88 % GR, MERCK) was used as activating agent for carbonization of algal biomass in a muffle furnace at an elevated temperature for certain time period. To remove the acid from carbonized material, it was first washed with dilute ammonia solution (AR grade, SARA Fine Chemicals Pvt. Ltd.) and then with distilled water and continued until the pH of the filtrate was found to be neutral. The carbonized material was left for drying in oven at 100 °C for overnight. It was ground and sieved to get the desired particle size. The efficiency of prepared carbon material was analyzed from decolorizing power of methylene blue or methylene blue decolorization (AR grade, MERCK) following standard procedure (Dutta et al. 2001). Response Surface Methodology was applied to optimize carbonization condition using Design Expert Software (8.0.6). Three parameters viz., weight ratio of dry algal biomass to activating agent (1:1–3:1), temperature (450–550 °C) and time of carbonization (1–2 h) were selected as input factors and decolorizing power or methylene blue decolorization as output response.

Design of experiments Response Surface Methodology (RSM) is a collection of mathematical and statistical technique that uses experimental data obtained from specified experimental design to model and optimize any process in which response (output variable) of interest is influenced by several independent variables (input variables) (Hameed et al. 2008; Chatterjee et al. 2012). Principally, this optimization process follows three major steps viz., performing the statistically designed experiments, estimating the coefficients in a mathematical model and predicting the responses and examining the adequacy of the model (Myers and Montgomery 1995; Sadhu et al. 2014). RSM helps to evaluate the relationships between the responses (Y) and input factors (Ravikumar et al. 2006).

where Y = response of the system, \(X_{ 1} , { }X_{ 2} , { }X_{ 3} \ldots X_{n} { = }\) input factors.

A second-order model can be constructed efficiently with central composite designs (CCD). This method is suitable for fitting a quadratic surface and it helps to optimize the effective parameters with a minimum number of experiments, as well as to analyze the interaction between the parameters (Hameed et al. 2008). Total number of experiments required can be calculated by using the equation:

where \(2^{n}\) are factorial runs with \(2n\) axial runs and \(n_{c}\) central runs. The central points are used to evaluate the experimental error and the reproducibility of the data (Chatterjee et al. 2012).

The experimental sequence was randomized in order to minimize the effects of the uncontrolled factors (Dutta et al. 2011). Second degree polynomial equation has been used to analyze the result of each run and to correlate the response with independent parameters. Polynomial equation can be stated in the form of following equation:

where \(\beta_{ 0} { = }\) constant coefficient, \(\beta_{i} { = }\) linear coefficient, \(\beta_{ii} { = }\) quadratic coefficient, \(\beta_{ij} { = }\) interaction coefficient (Sadhu et al. 2014).

Statistical parameters were analyzed using ANOVA. The maximum (+1) and minimum levels (-1) of three input factors viz., weight ratio of algal biomass to activating agent, time of carbonization and temperature were 3:1 and 1:1 (i.e. 3 and 1), 2 h and 1 h and 550 °C and 450 °C respectively. The experimental design as suggested by Design Expert Software (8.0.6) along with the values of responses is presented in Table 1. According to the software, the optimized condition for carbonization of algal biomass is obtained when weight ratio of biomass to activating agent, time of carbonization and temperature of carbonization have the values of 1.78:1, 1.69 h and 500.74 °C respectively. Algal biomass was carbonized at the optimum condition and used for further investigations of Cu(II) removal.

Characterization of adsorbent

Bulk density and solid density of dried algal biosorbent were determined following standard protocol (Dutta et al. 2001). Carbonized algal biomass was characterized in terms of solid density, bulk density, moisture content, volatile matter content and ash content following same protocol (Dutta et al. 2001). Scanning electron microscopy (SEM) and Fourier transform infrared (FTIR) spectroscopy studies were also performed for dried algal biomass, carbonized algal biomass and their Cu(II) loaded forms. Energy dispersive X-ray spectroscopy study was performed with dried algal biomass loaded with Cu(II).

Scanning electron microscopy (SEM) study

The topographical characterization of dried and carbonized algal biomass before and after Cu(II) removal were done through SEM (JEISS EVO 18, GERMANY) and SEM (JSM 6700F, JEOL, Japan), respectively. The samples were mounted on brass stubs using double-sided adhesive tape. The coated samples were brought into the SEM unit under vacuum. Once a certain pressure had been reached, the photographs were taken at the required magnification at room temperature. Chemical composition of dried algae loaded with Cu(II) was analyzed by energy dispersion X-ray spectrometer (FEI Quanta 200, USA).

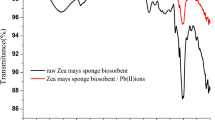

Fourier transform infrared (FTIR) study

FTIR spectroscopy was used to determine the functional groups present in dried algae and its carbonized form. The analysis was conducted for both the native adsorbent material and the material loaded with Cu(II) with the help of Fourier Transform Infrared machine (Nicolet iS10, Thermo Fischer Scientific, USA).

Removal of Cu(II) from aqueous solution

Kinetic study

To establish the mechanism of Cu(II) removal using algal adsorbents, kinetic study was done. A stock solution of Cu(II) (1000 mg/L) was prepared by dissolving definite amount of CuSO4·5H2O (AR grade, MERCK) in distilled water. Various concentrations of Cu(II) were prepared from the stock solution by diluting it with suitable amount of distilled water. Pre-weighted adsorbents (dried and carbonized) prepared from algal biomass were added separately to each flask containing 50 mL of metal solution and agitated in a BOD incubator with shaker (Make Digitech, India) at 35 ± 1 °C. Initially experiments were conducted for 60 min; however, no remarkable change in concentration was observed after 20 min. Therefore, during kinetic study, all the experiments were run for 20 min only. To assess Cu(II) removal, samples were collected at different time intervals. The solutions were then centrifuged at 5000 rpm for 10 min and supernatant was analyzed for Cu(II) concentration spectrophotometrically using UV–Visible Spectrophotometer (TECHCOM, UV 2300) at 460 nm (Greenberg et al. 1992). Sorption kinetics of Cu(II) by dried biomass and its carbonized form has been studied by varying three operating parameters viz., initial Cu(II) concentration (10–50 mg/L), solution pH (2–6) and adsorbent dose in a judicial manner. Sorption of Cu(II) is highly dependent on adsorbent dose. Initially sorption of Cu(II) was examined with different amount of dried biomass and its carbonized form separately and found that 0.5 g of carbonized biomass had similar capacity as that obtained with 1.0 g of dried biomass under identical condition. Therefore, during kinetic study, doses of dried algal biomass and carbonized biomass were varied individually from 0.1 to 1.0 g and from 0.1 to 0.5 g, respectively, and all other parameters were kept constant.

Equilibrium study

For equilibrium study 100 mL Cu(II) stock solution (1000 mg/L) was prepared and diluted to obtain desired concentration (10–150 mg/L). Experiments were conducted with adsorbent dose i.e., 0.5 g of dried biomass and 0.25 g of carbonized biomass. Pre-weighted adsorbent was added to each flask containing 50 mL of test metal solution and placed for 60 min in a BOD incubator with shaker at a constant temperature of 35 °C. Finally, the solutions were centrifuged and supernatant was analyzed for residual Cu(II) concentration spectrophotometrically.

Conductometric analysis of adsorbents

To evaluate the ionic property of dried alga and its activated carbon with and without loading of Cu(II), a conductometric analysis was performed in distilled water, considered as reference, which had the conductivity of 2.6 µs/cm. Equal amount (0.25 g) of each sample was added in 100 mL of distilled water separately and the change in conductivity was recorded for 3 h.

Optimization of Cu(II) removal by RSM

Response Surface Methodology was employed for optimization of Cu(II) removal from its aqueous solution. The efficiency of both dried and carbonized biomass was compared for sorption of Cu(II) and the removal condition was optimized using Design Expert Software (version 8.0.6). Three numeric parameters viz., amount of adsorbent, initial Cu(II) concentration, solution pH and one categoric factor viz., type of adsorbent (dried and carbonized algal biomass) were selected as input factors and percentage removal of Cu(II) as response. From kinetic study in both the cases it is seen that the size of algal adsorbent has negligible effect on the removal of Cu(II) under the ranges (53–125 µ) studied. Therefore, during optimization of removal process, adsorbent size was not selected as input parameters. Furthermore, kinetic study reveals that the percentage removal of Cu(II) has reached to its equilibrium value within 20 min. Thus, run time has been fixed to 30 min during optimization study. Factors of optimization process were maintained according to the design made by the software. Residual concentration of Cu(II) was analyzed spectrophotometrically at 460 nm. The maximum (+1) and minimum levels (−1) of three input factors viz., initial Cu(II) concentration, adsorbent dose and solution pH were 50 and 20 mg/L, 0.25 and 0.1 g and 6 and 4, respectively. The volume of solution was kept 50 mL in each of the experimental run during optimization study.

Regeneration of adsorbents

Efficient regeneration of adsorbent after sorption of metal ions is an important step to use that adsorbent in industrial applications. Reusability of any adsorbent can be tested by its sorption capacity in successive sorption and desorption cycles. Desorption study can be carried out by stirring the dried biomass and its activated carbon with suitable desorbing agent separately. In the present study, 0.1 M HCl has been selected for desorption of Cu(II) from adsorbents. Adsorption of Cu(II) was done at optimum condition, sample produced after adsorption is termed as spent adsorbent.

In order to show the reusability of the adsorbent material, three successive sorption/desorption cycle was performed. 0.5 g of spent adsorbent produced at optimum condition of adsorption was suspended in 150 mL of 0.1 M HCl in order to regenerate it. After gentle agitation for 60 min, the solution was centrifuged and supernatant was analyzed for metal concentration. The regenerated biomass was washed with distilled water to remove excess of acid and dried again to use it for next sorption/desorption cycle.

Results and discussions

Optimization of carbonization condition and preparation of carbonized algal biomass

The statistical design of the experiments as given by Design Expert software (8.0.6) is shown in Table 1. As suggested by the software, the ratio of maximum response (9.523) and minimum response (4.444) has been found as 2.143, no transformation is required. The dependent output response has been modeled with three independent input parameters using ANOVA. Quadratic process order has been selected for regression analysis of the experimental data and the final equation in terms of coded factor is given below:

where, R 1 = decolorizing power (mg/g), A 1 = time of carbonization (h), B 1 = weight ratio (g/g), C 1 = temperature of carbonization (°C). The values of \(R{\text{-squared,}}\) \({\text{Adj}}\,R{\text{-squared}}\) and \({\text{Pred}}\,R{\text{-squared}}\) have been found as 0.987, 0.975 and 0.891, respectively. Based on the analysis done by ANOVA, it is seen that time of carbonization and weight ratio has significant effect on decolorizing power. Quadratic effects of all the three parameters have significant effect. The conjugate effect of time of carbonization and weight ratio has been found to be significant.

Figure 1 shows the combined effect of time of carbonization and weight ratio on decolorizing power at constant temperature of carbonization (500 °C). From figure it is evident that with increase in time of carbonization from 1 to 2 h, decolorizing power increases from 7.34 to 9.73 mg/g with weight ratio of 1:1 and decreases from 6.59 to 6.09 mg/g with weight ratio of 3:1. With higher amount of activating agent, when time of carbonization increases, decolorization power increases, whereas with lower activating agent the reverse is true; however, variation is less. Thus, it can be stated that with higher amount of activating agent, time has a significant effect on decolorizing power. Again, with increase in weight ratio from 1:1 to 3:1, decolorizing power decreases from 7.34 to 6.59 mg/g for 1 h of carbonization and from 9.73 to 6.09 mg/g for 2 h of carbonization. Maximum methylene blue decolorization (9.73 mg/g) has been found at weight ratio 1:1 and 2 h of carbonization time. Lower weight ratio denotes the presence of higher amount of activating agent for carbon preparation and hence, it is clear that amount of activating agent has pronounced direct effect on carbonization of algal biomass. Thus, it can be stated that an efficient carbon material can be prepared at lower weight ratio and higher time of carbonization.

According to the Design Expert Software, the optimized condition is obtained when time of carbonization, weight ratio of dried algal biomass to activating agent and temperature of carbonization have the values of 1.69 h, 1.78:1 and 500.74 °C, respectively. Experimental decolorizing power (9.091 mg/g) is in close proximity with the estimated value (9.79 mg/g). The carbonized algal biomass obtained at this condition has been used for further studies on Cu(II) sorption.

Characterization of algal adsorbents

Characterization of dried algal biomass has been done in terms of bulk density and solid density and found as 501.13 and 1600.13 kg/m3, respectively. Carbonized biomass has been characterized as bulk density: 682.52 kg/m3; solid density: 1833.45 kg/m3. Proximate analysis of carbonized algal biomass shows moisture content: 5.26 %; ash content: 47.68 %; volatile matter: 12.83 %; fixed carbon: 34.23 %. High amount of ash content has been found in the carbonized algal biomass. The probable reason for such high value is the presence of large amount of the inorganic compounds containing elements like silicon, aluminum, calcium, etc., in the dried biomass as evident from energy dispersive X-ray spectroscopy study.

Scanning electron microscopy (SEM)

Figure 2a–d represents the SEM images of dried algal biomass and Cu(II) loaded algal biomass, carbonized algal biomass and Cu(II) loaded carbonized algal biomass, respectively. SEM study is done to get topographical characterization of adsorbents. A smoothening effect is observed in Fig. 2b, d. This may be due to the adsorption of Cu(II) on the surface of adsorbents. Chemical composition of algal biomass has been analyzed using energy dispersive X-ray spectroscopy. Figure 3 shows the chemical composition of the native dry algal sample loaded with Cu(II). Algal sample has elements like oxygen, silicon, calcium and aluminum on its surface.

Fourier transform infrared (FTIR) spectroscopy

Fourier transform infrared spectroscopy has been used to analyze the interaction between adsorbent and Cu(II) by examining the changes in vibrational frequency of each functional groups in the adsorbent after adsorption of Cu(II). Figure 4a–d represents FTIR spectra of dried algal biomass and Cu(II) loaded algal biomass, carbonized algal biomass and Cu(II) loaded carbonized algal biomass, respectively. It is seen that the number of peaks vis-à-vis functional groups is more in case of dried algal biomass (Fig. 4a, b) than that in case of carbonized algal biomass (Fig. 4c, d). This is obvious due to the fact that during carbonization process, which is a destructive carbon enrichment process, various chemical reactions such as devolatilization, decarboxylation, etc., happen and, thereby, the number of functional groups gets reduced. Several functional groups such as amine, amide, alkene, ether, alcohol and aromatic have been found in the dried biomass while amine, carbonyl, alkyl halide and ether groups have been found in the carbonized biomass. Alteration of position of certain peaks has been observed in the FTIR spectra of both the adsorbents after adsorption of Cu(II) (Fig. 4b, d). According to the literature, amine groups are responsible for adsorption of Cu(II) (Flouty and Estephane 2012). In Fig 4a, c peaks at 3397 and 3428 cm−1 confirm the presence of amine group in dried and carbonized biomass, respectively, and shift to 3402 and 3412 cm−1, respectively, after adsorption of Cu(II). Other dominant peaks in dried biomass are at about 700 and 840 cm−1 shifts to 669 and 849 cm−1 respectively after Cu(II) loading and confirms the involvement of –CH bending in Cu(II) adsorption. The peak at 1487 cm−1, indicating the C=C stretch, shifts to 1486 cm−1 after metal adsorption. Along with the amine group present in the carbonized biomass some other leading peaks at 602, 1085, 1734 cm−1 show the existence of C–Cl stretch, C–O stretch and C=O stretch, respectively, and shift to 605, 1084 and 1733 cm−1, respectively, due to Cu(II) adsorption. Thus it can be stated that amine, alkenes and aromatic groups in the case of dried biomass and amine, carbonyl, alkyl halide and ether in the case of carbonized biomass may be involved in the sorption of Cu(II).

Removal of Cu(II) from aqueous solution

Selection of adsorbent size

Size of adsorbent is an important parameter influencing heavy metal adsorption from aqueous solution. Figure 5 represents the effect of adsorbent size ranging from 53 to 125 µ on the adsorption of Cu(II) for dried and carbonized biomass. Other parameters viz., initial Cu(II) concentration, solution pH and temperature have been kept constant at 25 mg/L, 6 and 35 °C, respectively, with adsorbent dose of 0.5 g for dried and 0.25 g for carbonized algal biomass. Generally, small size particle provides large surface area for adsorption resulting higher removal of pollutant. From Fig. 5, it is clear that the percentage removal of Cu(II) is almost same for 53 and 90 µ for both the adsorbents whereas it is less with 125 µ size. Though lower size gives slightly better result, the grinding cost to get that size will be high. Thus, during other studies adsorbent size has been kept constant at 90 µ.

Kinetic study

The kinetics of adsorption describes the rate of Cu(II) uptake from aqueous solution. It has been observed that removal of Cu(II) by algal adsorbents involves two phases: a relatively fast phase (2 min) followed by a slow step that extends until the equilibrium was reached. Major removal has been achieved within 2 min of contact time and after 20 min, plateau region i.e., little variation in concentration of Cu(II) with time is observed. Thus, it can be said that equilibrium is reached in 20 min. It has also been found that Cu(II) can be removed maximum about 87.99 and 99.15 % with initial Cu(II) concentration of 10 and 25 mg/L for dried and carbonized algae, respectively, at an adsorbent dose of 10 g/L in 20 min of contact time and at optimum pH 6 in both the cases.

Effect of adsorbent dose Effect of adsorbent (dried and carbonized biomass) dose on sorption of copper ion, as shown in Fig. 6, has been studied keeping other parameters constant viz., initial Cu(II) concentration, solution pH, adsorbent size and temperature at 25 mg/L, 6, 90 µ and 35 °C, respectively. Figure 6 reveals that sorption of Cu(II) is directly proportional with amount of adsorbents. Percentage removal of Cu(II) has been increased from 56.32 to 83.48 % and from 50.25 to 99.15 % when amount of dried biomass increases from 0.1 g to 1.0 g and carbonized biomass increases from 0.1 to 0.5 g, respectively. For dried algal biomass, it is also found that percentage removal becomes independent on amount of adsorbent when exceeds 0.25 g at the present operating condition. This may be due to the availability of unsaturated active sites of adsorbent when it is present in excess amount.

Effect of initial Cu(II) concentration Fig. 7 represents the variation of percentage removal of Cu(II) with time using dried algal biomass and its carbonized form when initial Cu(II) concentration varies from 10 to 50 mg/L. Other parameters viz., solution pH, adsorbent size and temperature have been kept constant at 6, 90 µ and 35 °C, respectively. Experiments have been performed at a constant adsorbent dose of 0.5 g of dried material and 0.25 g of carbonized biomass. From Fig. 7, it is evident that the rate of sorption of Cu(II) is high at lower Cu(II) concentration whereas removal is less at higher concentration for both adsorbents. When Cu(II) concentration has been increased from 10 to 50 mg/L, percentage removal decreases from 87.99 to 77.03 % for dried biomass and from 92.92 to 63.37 % for carbonized biomass. This may be due to the saturation of the adsorbent at higher concentration of Cu(II). By judicial screening of the results shown in Fig. 7, it can be stated that carbonized biomass is more efficient than dry biomass in Cu(II) removal from aqueous solution at lower concentration while at higher concentration dry biomass is performing better than the carbonized material. Firstly, the higher removal at lower concentration by carbonized biomass indicates that the process is adsorption rate controlled rather than mass transfer rate controlled. Carbonized biomass is porous in nature and thereby has more surface area than that of dried algal biomass. Therefore, it is efficient to adsorb Cu(II) even at lower concentration. On the other hand, the interaction between characteristic functional groups present on dried algal biomass with Cu(II) ions in solution is more in case of higher initial concentration of Cu(II) than that in case of lower one. Therefore, dried algal biomass is efficient to remove Cu(II) at both higher and lower concentrations.

Effect of initial solution pH on Cu(II) adsorption Solution pH is an important parameter influencing heavy metal adsorption from aqueous solution. It affects both the surface charge of adsorbent and the degree of ionization of the heavy metal in solution (Aksu and Isoglu 2005). Figure 8 reveals the effect of solution pH (2–6) on the sorption of Cu(II). The percentage removal of Cu(II) has been plotted against time at various pH. For all the cases initial Cu(II) concentration, adsorbent size and temperature are kept constant at 25 mg/L, 90 µ and 35 °C, respectively, with adsorbent dose of dried biomass as 0.5 g and carbonized biomass as 0.25 g. Uslu and Tanyol (2006) observed that at pH higher than 7, the precipitation of insoluble copper hydroxides had occurred, which reduced the availability of free metal ion in the solution and restricting the true adsorption studies. Therefore, in the present investigation, sorption of Cu(II) has been studied in acidic pH only. Maximum 82.93 and 85.15 % adsorption has been observed at pH 6.0 with dried and carbonized material respectively. The probable reason for this could be that at lower acidic pH availability of H+ ions are more and Cu(II) ions compete with H+ ions for free active sites. On the other hand at higher acidic pH less availability of H+ ions increases the percentage removal of Cu(II) from aqueous solution.

Kinetic model

Kinetic models have been used to investigate the mechanism of sorption and potential rate controlling step, which is helpful for selecting optimum operating conditions for the full-scale batch process. Data obtained during kinetic study were analyzed using three models i.e., Morris–Weber model, Lagergren model and Pseudo-second-order model. From the expression of Lagergren pseudo-first-order model, values of adsorption rate constant (\(k_{L}\)) for the Cu(II) adsorption onto the adsorbents (dried and carbonized algal biomass) have been determined from the straight line plot of \({\text{log (}}q_{e} - q_{t} )\) against t. Values of correlation coefficient (Table 2) indicate that the rate of Cu(II) removal onto the adsorbents does not follow the pseudo-first-order equation. Kinetic data have been analyzed with the Morris–Weber model but the values of correlation coefficient have been found to be low. In the case of pseudo-second-order model values of adsorption rate constant \(k_{p}\) have been determined from the intercept of the plots of \(t /q_{t}\) against t. The values of correlation coefficient have been found to be very high (R 2 ≥ 0.99) with all examined data. This shows that the model can be applied for the entire adsorption process and confirms that the sorption of Cu(II) onto both of the adsorbents follows the pseudo-second-order kinetic model and the rate limiting step is of chemisorption nature. Root mean square error (RMSE), another statistical parameter, has also been used to validate the model. The expression of RMSE is shown below:

where, \(q_{{t , {\text{expt}}}} { = }\) solid phase concentration obtained experimentally at time t (mg/g), \(q_{{t , {\text{theo}}}} { = }\) simulated solid phase concentration at time t (mg/g), N = number of experiments. From Table 2, it is seen that RMSE has the lowest value when kinetic data are being analyzed with pseudo-second-order model. This reconfirms the validation of pseudo-second-order model in analyzing kinetic data.

Equilibrium study

Equilibrium study has been done with both of the adsorbents at temperature 35 °C. Equilibrium data have been analyzed using two different adsorption isotherm models viz., Langmuir adsorption isotherm model and Freundlich adsorption isotherm model. Langmuir isotherm assumes that there is finite number of binding sites distributed homogeneously over the surface of adsorbent while Freundlich isotherm assumes heterogeneous surface of the adsorbent (Kiran and Thanasekaran 2011). Regression coefficients have been found to be higher in the case of Langmuir isotherm than the other one (Table 3). Thus, it can be concluded that monolayer biosorption of Cu(II) on homogeneous surface dominates. High values of \(q^{ 0}\) and \(K_{L}\) are desirable for good adsorbent. The maximum removal capacity of Cu(II) with dried and carbonized biomass is found as 35.71 and 8.33 mg/g, respectively. Less removal capacity of carbonized biomass in comparison to dried material may be due to its inefficient adsorption property with higher Cu(II) concentration.

Conductometric analysis of adsorbents

Conductivity analysis has been performed to understand the ionic property of adsorbents. Figure 9 shows the temporal change in conductivity of solution in which the adsorbents have been immersed. From figure it is seen that conductivity of dried biomass immersed solution is maximum and lowest with carbonized biomass loaded with Cu(II). As observed in FTIR study, dried algal biomass posses more functional groups on the surface than carbonized biomass. Higher conductivity of solution with dried algal biomass may be due to the release of large number of ionic substances. Lower conductivity of solution with adsorbents loaded with Cu(II) may be because of the fact that the adsorption of Cu(II) on both the adsorbents is chemisorptive in nature, as discussed in “Kinetic model”. Thus, the bonding between Cu(II) with functional groups present on adsorbents is very strong and there is little chance of Cu(II) to get released into the solution when adsorbents loaded with Cu(II) will be immersed into the water and thereby, lower conductivity results. Carbonization of biomass decreases the availability of free ionic substances in the solution resulting in lower conductivity.

Optimization of Cu(II) removal

RSM was used to optimize process variables for removal of Cu(II) from aqueous solution. Three numeric parameters viz., initial Cu(II) concentration (\(A_{ 2}\), mg/L), adsorbent dose (\(B_{ 2}\), g) and solution pH (\(C_{ 2}\)) and one categoric factor viz., type of adsorbent (\(D_{ 2}\)) i.e., dried and carbonized algal biomass, are considered as input variables and percentage removal of Cu(II) (\(R_{ 2}\)) as response. The level 1 and 2 of \(D_{ 2}\) stands for dried and carbonized biomass, respectively. Design Expert Software (version 8.0.6) has been used to optimize the removal condition using dried and carbonized algal biomass together. For three independent variables, total number of tests required is

As the categoric factor is one hence total number of experiments required for two adsorbent is 40. The statistical design made by the software and the responses found at specified condition are shown in Table 4. Quadratic process order has been selected for regression analysis of the experimental data as analyzed by ANOVA. The ratio of maximum response (95.082) and minimum response (24.297) has been found as 3.913. Thus for this process order no transformation is required.

Final regression functions in terms of actual factors for level 1 of \(D_{ 2}\) (dried algal biomass):

Final regression functions in terms of actual factors for level 2 of \(D_{ 2}\) (carbonized biomass):

The statistical parameters such as \(R{\text{-squared,}}\) \({\text{Adj}}\,R{\text{-squared}}\) and \({\text{Pred}}\,R{\text{-squared}}\) have been obtained as 0.949, 0.924 and 0.832 respectively. Analysis by ANOVA explores that all the three numeric factors and one categoric factor have significant effect on Cu(II) removal. Quadratic effect of initial Cu(II) concentration has been found as significant. According to the Design Expert Software the optimum response using dried and carbonized algal biomass obtained when initial Cu(II) concentration, adsorbent dose and solution pH are 20 mg/L, 0.25 g and 6 respectively for both of the adsorbent. Experimental percentage removal of Cu(II) has been found as 90.66 and 95.08 % with dried and carbonized material respectively which is in comparable with the estimated values i.e., 92.68 and 95.14 %, respectively.

Figure 10 shows the interactive effect of initial Cu(II) concentration with different types of adsorbent (dried and carbonized). From figure it is clear that with lower initial Cu(II) concentration (20 mg/L), percentage removal of Cu(II) is same for both the adsorbent while at higher concentration (50 mg/L), the adsorption capability of dried algal biomass is much more than that of carbonized biomass. From Fig. 10, it is evident that with increase in initial concentration from 20 to 50 mg/L, the maximum and minimum removal of Cu(II) by dried algal biomass varies from 80.39 to 57.69 % and by carbonized algal biomass from 80.39 to 49.09 % when other parameters viz., adsorbent dose and solution pH are kept constant. The present observation leads to conclude that at lower concentration of Cu(II) any type of adsorbent can be used while with solution of higher concentration, dried algal biomass is the only choice.

Regeneration of adsorbent

Desorption study has been performed with 0.1 M HCl. Three successive cycles of sorption and desorption have been performed in a batch contactor. Adsorption capacity has been found as follows: first cycle, 3.94 mg/g; second cycle, 3.74 mg/g; third cycle, 3.59 mg/g with dried alga and first cycle, 4.09 mg/g; second cycle, 3.68 mg/g; third cycle, 3.3 mg/g with carbonized biomass. By comparing the adsorption capacity of dried biomass and carbonized biomass, it can be concluded that adsorption capacity of dried alga is higher than carbonized alga in successive sorption/desorption cycle, this result is in conformity with the Langmuir adsorption capacity. However, more than 80 % carbonized biomass has been regenerated at the end of the 3rd cycle while 70 % regeneration has been seen with dried alga. From the present observation, one may expect better regeneration capability of carbonized biomass than that of dried algal biomass; however, it is not the true scenario. Since adsorption of Cu(II) is more with dried alga than that of carbonized alga, the total desorbed amount of Cu(II) is comparable with both the adsorbent.

Conclusion

The potential of L. majuscula, a cyanobacterium, in removal of Cu(II) from simulated wastewater has been explored in the present study. The sorption of Cu(II) onto the adsorbents increases with increase in solution pH 2–6. At pH higher than 7, the precipitation of insoluble metal hydroxides is observed that restricts the true biosorption studies. The kinetics of the sorption process was found to follow Pseudo-second-order model (PSOM). The maximum Cu(II) uptake capacity has been found 35.71 and 8.33 mg/g for dried and carbonized algae, respectively. Study reveals that carbonized algal material is highly efficient only at lower Cu(II) concentration whereas dried algal biomass has been found effective both at lower and higher Cu(II) concentration. To optimize Cu(II) removal, RSM has been employed considering type of adsorbent namely dried and carbonized algal biomass, as categoric factor. Percentage removal of Cu(II) has been found optimum with initial Cu(II) concentration of 20 mg/L, adsorbent dose of 0.25 g at solution pH 6 with both the adsorbents. Owing to the advantage of high metal biosorption capacity, the dried biomass of L. majuscula can efficiently be used as an adsorbent for removal of heavy metals from wastewater streams.

Reference

Aksu Z, Isoglu IA (2005) Removal of copper (II) ions from aqueous solution by biosorption onto agricultural waste sugar beet pulp. Process Biochem 40:3031–3044

Chatterjee S, Kumar A, Basu S, Dutta S (2012) Application of Response Surface Methodology for Methylene Blue dye removal from aqueous solution using low cost adsorbent. Chem Eng J 181–182:289–299

Das N, Vimala R, Karthika P (2008) Biosorption of heavy metals—an overview. Indian J Biotechnol 7:159–169

Dutta S, Basu JK, Ghar RN (2001) Studies on adsorption of p-nitrophenol on charred saw-dust. Sep Purif Technol 21:227–235

Dutta S, Bhattacharyya A, Ganguly A, Gupta S, Basu S (2011) Application of Response Surface Methodology for preparation of low-cost adsorbent from citrus fruit peel and for removal of Methylene Blue. Desalination 275:26–36

Flouty R, Estephane G (2012) Bioaccumulation and biosorption of copper and lead by a unicellular algae Chlamydomonas reinhardtii in single and binary metal systems: A comparative study. J Environ Manage 111:106–114

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manage 92:407–418

Greenberg AE, Clesceri LS, Eaton AD (1992) Standard methods for the examination of water and wastewater, 18th edn. American Public Health Association, Washington, DC

Gupta VK, Rastogi A, Saini VK, Jain N (2006) Biosorption of copper (II) from aqueous solutions by Spirogyra species. J Colloid Interf Sci 296:59–63

Hameed BH, Tan IAW, Ahmed AL (2008) Optimization of basic dye removal by oil palm fibre-based activated carbon using response surface methodology. J Hazard Mater 158:324–332

Karacan F, Ozden U, Karacan S (2007) Optimization of manufacturing conditions for activated carbon from Turkish lignite by chemical activation using response surface methodology. Appl Therm Eng 27:1212–1218

Kiran B, Kaushik A (2008) Cyanobacterial biosorption of Cr(VI): application of two parameter and Bohart Adams models for batch and column studies. Chem Eng J 144:391–399

Kiran B, Thanasekaran K (2011) Copper biosorption on Lyngbya putealis: application of response surface methodology (RSM). Int Biodeter Biodegr 65:840–845

Kundu N, Pal M, Saha S (2008) East Kolkata wetlands: a resource recovery system through productive activities. In: 12th World Lake Conference, pp 868–881

Myers RH, Montgomery DC (1995) Response surface methodology: process and product optimization using designed experiments, 1st edn. Wiley, New York

Papageorgiou SK, Kouvelos EP, Katsaros FK (2008) Calcium alginate beads from Laminaria digitata for the removal of Cu+2 and Cd+2 from dilute aqueous metal solutions. Desalination 224:293–306

Pittman JK, Dean AP, Osundeko O (2011) The potential of sustainable algal biofuel production using wastewater resources. Bioresour Technol 102:17–25

Ravikumar K, Ramalingam S, Krishnan S, Balu K (2006) Application of response surface methodology to optimize the process variables for Reactive Red and Acid Brown dye removal using a novel adsorbent. Dyes Pigments 70:18–26

Ravikumar K, Krishnan S, Balu K, Ramalingam S (2007) Optimization of process variables by the application of response surface methodology for dye removal using a novel adsorbent. Dyes Pigments 72:66–74

Sadhu K, Mukherjee A, Shukla SK, Adhikari K, Dutta S (2014) Adsorptive removal of phenol from coke-oven waste water using Gondwana shale, India: experiment, modeling and optimization. Desalin Water Treat 52(34–36):6492–6504

Sahu JN, Acharya J, Meikap BC (2009) Response surface modeling and optimization of chromium (VI) removal from aqueous solution using Tamarind wood activated carbon in batch process. J Hazard Mater 172:818–825

Silva JP, Sousa S, Goncalves I, Porter JJ, Ferreira-Dias S (2004) Modeling adsorption of acid orange 7 dye in aqueous solutions to spent brewery grains. Sep Purif Technol 40:163–170

Uslu G, Tanyol M (2006) Equilibrium and thermodynamic parameters of single and binary mixture biosorption of lead (II) and copper (II) ions onto Pseudomonas putida: effect of temperature. J Hazard Mater 135:87–93

Yilmazer P, Saracoglu N (2009) Bioaccumulation and biosorption of copper (II) and chromium (III) from aqueous solutions by Pichia stipitis yeast. J Chem Technol Biot 84:604–610

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kushwaha, D., Dutta, S. Experiment, modeling and optimization of liquid phase adsorption of Cu(II) using dried and carbonized biomass of Lyngbya majuscula . Appl Water Sci 7, 935–949 (2017). https://doi.org/10.1007/s13201-015-0304-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-015-0304-0