Abstract

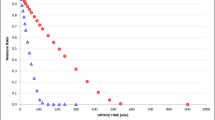

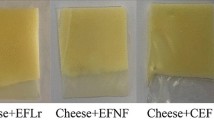

Casein and whey protein concentrate (WPC) films, plasticized with glycerol and sorbitol independently, were prepared by casting. The film thickness, water vapour and oxygen permeation and tensile and moisture sorption properties of the films were determined. The tensile strength (TS), tensile strain (TE) and elastic modulus (EM) of the films ranged from 0.71 to 4.58 MPa, 19.22 to 66.63 % and 2.05 to 6.93 MPa, respectively. The film properties were influenced by the type of biopolymer (casein and whey protein concentrate), plasticizer and its concentration. Increasing the plasticizer concentration, increased the film thickness, TE and water vapour permeability (WVP), but decreased the TS and EM. As the concentration of plasticizer increased to the highest level, the film thickness increased from 0.168 to 0.305 mm for glycerol-plasticized films and from 0.251 to 0.326 mm for sorbitol-plasticized films. The film thickness increased because the amount of plasticizer in the film network increased and the amount of biopolymer remained same. Casein films showed superior tensile properties as compared to WPC films. The WVP of both casein and WPC films lied between 3.87 and 13.97 g.mm./(m2.h.kPa). The moisture sorption isotherms of both films were typical of high-protein material, and were adequately described by the GAB model. The oxygen permeability of casein films was relatively lower than that of WPC films, regardless of the plasticizer used. The sensory data revealed that the organoleptic quality of Cheddar cheese was unaffected by milk-protein film packaging.

Similar content being viewed by others

References

Anker M, Stading M, Hermansson A-M (2000) Relationship between the microstructure and the mechanical and barrier properties of whey protein films. J Agric Food Chem 48(9):3806–3816

Arvanitoyannis I, Biliaderis CG (1998) Physical properties of polyol-plasticized edible films made from sodium caseinate and soluble starch blends. Food Chem 62(3):333–342

ASTM (2009) Standard test method for determining gas permeability characteristics of plastic film and sheeting. D1434-82. In: Annual Book of ASTM Standards, American Society for Testing and Materials, Philadelphia, PA

Banker GS (1966) Film coating, theory and practice. J Pharm Sci 55(1):81–89

BIS: SP-18 (1981) Handbook of food analysis Part XI: Dairy products. Indian Standards Institution, New Delhi

Cuq B, Gontard N, Aymard C, Guilbert S (1997) Relative humidity and temperature effects on mechanical and water vapor barrier properties of myofibrillar proteinbased films. Polym Gels Netw 5(1):1–15

Dangaran K, Tomasula PM, Qi P (2009) Structure and function of protein-based edible films and coatings. In: Embuscado ME, Huber KC (eds) Edible films and coatings for food applications. Springer, Dordrecht, pp 25–56

Fairley P, Monahan FJ, German JB, Krochta JM (1996) Mechanical properties and water vapor permeability of edible films from whey protein isolate and sodium dodecyl sulfate. J Agric Food Chem 44(2):438–443

Frederiksen CS, Haugaard VK, Poll L, Becker EM (2003) Light-induced quality changes in plain yoghurt packed in polylactate and polystyrene. Eur Food Res Technol 217(1):61–69

Gennadios A, McHugh T, Weller C, Krochta JM (1994) Edible films and coatings based on proteins. In: Krochta JM, Baldwin EA, Carriedo NB (eds) Edible films and coatings to improve food quality. Technomic, Lancaster, pp 201–278

Holm VK, Risbo J, Mortensen G (2006) Quality changes in semi-hard cheese packaged in a poly(lactic acid) material. Food Chem 97(3):401–410

Kampf N, Nussinovitch A (2000) Hydrocolloid coating of cheeses. Food Hydrocoll 14:531–537

King RL (1962) Oxidation of milk fat globule membrane material, thiobarbituric acid reaction as a measure of oxidized flavor in milk and model systems. J Dairy Sci 45(10):1165–1171

Krochta JM (1992) Control of mass transfer in foods with edible-coatings and films. In: Singh RP, Wirakarstakusumah MA (eds) Advances in food engineering. CRC Press, Boca Raton, pp 517–538

Krochta JM, Mulder-Johnston CD (1997) Edible and biodegradable polymer films: challenges and opportunities. Food Tech 51(2):61–74

Maynes JR, Krochta JM (1994) Properties of edible films from total milk protein. J Food Sci 59(4):909–911

McHugh TH, Krochta JM (1994a) Sorbitol- vs. Glycerol-plasticized whey protein edible films: integrated oxygen permeability and tensile property evaluation. J Agric Food Chem 42(4):841–845

McHugh TH, Krochta JM (1994b) Milk-protein-based edible films and coatings. Food Tech 48(1):97–103

McHugh TH, Aujard JF, Krochta JM (1994) Plasticized whey protein edible films: water vapor permeability properties. J Food Sci 59(2):416–419, 423

Pérez-Gago MB, Krochta JM (2002) Formation and properties of whey protein films and coatings. In: Gennadios A (ed) Potein-based films and coatings. CRC Press, Boca Raton, pp 159–180

Pérez-Gago MB, Nadaud P, Krochta JM (1999) Water vapor permeability, solubility, and tensile properties of heat-denatured versus native whey protein films. J Food Sci 64(6):1034–1037

Sothornvit R, Krochta JM (2001) Plasticizer effect on mechanical properties of beta-lactoglobulin films. J Food Eng 50(3):149–155

Acknowledgements

We gratefully acknowledge the valuable help extended by Dr. A.R. Indiramma, Principal Scientist, Food Packaging Technology Section and Mr. Srinivas Korra, Technical Officer, Central Food Technology Research Institute, Mysore in testing the oxygen permeability of the films. We also thank the technical assistance offered by Mr. Ravinder Singh, Dairy Engineering Section of NDRI, Bangalore in the preparation and tensile testing of films.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wagh, Y.R., Pushpadass, H.A., Emerald, F.M.E. et al. Preparation and characterization of milk protein films and their application for packaging of Cheddar cheese. J Food Sci Technol 51, 3767–3775 (2014). https://doi.org/10.1007/s13197-012-0916-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0916-4