Abstract

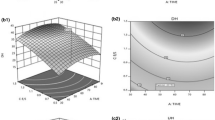

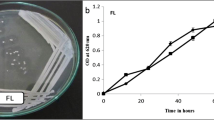

Protein hydrolysates were produced from shrimp waste mainly comprising head and shell of Penaeus monodon by enzymatic hydrolysis for 90 min using four microbial proteases (Alcalase, Neutrase, Protamex, Flavourzyme) where PR(%) and DH (%) of respective enzymes were compared to select best of the lot. Alcalase, which showed the best result, was used to optimize hydrolysis conditions for shrimp waste hydrolysis by response surface methodology using a central composite design. A model equation was proposed to determine effects of temperature, pH, enzyme/substrate ratio and time on DH where optimum values found to be 59.37 °C, 8.25, 1.84% and 84.42 min. for maximum degree of hydrolysis 33.13% respectively. The model showed a good fit in experimental data because 92.13% of the variability within the range of values studied could be explained by it. The protein hydrolysate obtained contained high protein content (72.3%) and amino acid (529.93 mg/gm) of which essential amino acid and flavour amino acid were was 54.67–55.93% and 39.27–38.32% respectively. Protein efficiency ratio (PER) (2.99) and chemical score (1.05) of hydrolysate was suitable enough to recommend as a functional food additive.

Similar content being viewed by others

References

Adler-Nissen J (1986) Enzymatic hydrolysis of food proteins. Elsevier Applied Science Publishers Ltd, London, p 427

AOAC (1995) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Arlington

Aunstrup K (1980). Proteinases. In Microbial enzymes and bioconvertions (Edited by Rose A. Academic Press, New York, pp. 50–112

Beak HH, Cadwallader KR (1995) Enzymatic hydrolysis of crayfish processing byproducts. J Food Sci 60:929–935

Benjakul S, Morrisey T (1997) Protein hydrolysates from Pacific whiting solid wastes. J Agric Food Chem 45:3423–3430

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Box GEP, Wilson KG (1951) On the experimental attainment of optimum conditions. J R Stat Soc 13:1–45

Cheison SC, Wang Z, Xu SY (2007) Use of response surface methodology to optimise the hydrolysis of whey protein isolate in a tangential flow filter membrane reactor. J Food Eng 80:1134–1145

Deng SG, Peng ZY, Yang P, Xia XZ (2002) Application of multienzymatic method in fermented fish sauce production from Harengula zunasi’s offal. Food Ferment Ind 28:32–36

Diniz FM, Martin AM (1997a) Effects of the extent of enzymatic hydrolysis on the functional properties of shark protein hydrolysate. Lebensm Wiss Technol 30:266–272

Diniz FM, Martin AM (1997b) Fish protein hydrolysates by enzymatic processing. Agro Food Ind Hi Tec 8:9–13

FAO/WHO (1990) Protein quality evaluation. Reports of a joint FAO/WHO expert consultation. Rome Food and Agriculture Organization of the United Nations. Food Nutr Paper 51:1–66

Ghosh AK, Naskar AK, Jana ML, Khowala S, Sengupta S (1995) Biotechnol Prog USA 11:452–456

Gildberg A, Stenberg E (2001) A new process for advanced utilization of shrimp waste. Process Biochem 36:809–812

Giovanni M (1983) Response surface methodology and product optimization. Food Technol 37:41–45

Holanda HD, Netto FM (2002) Optimization of the conditions for the enzyme hydrolysis of shrimp residue, using response surface methodology (RSM). In book of abstracts, 2002 IFT Annual Meeting, Anaheim, Calif., USA, P 194

Ibrahim HM, Salama MF, El-Banna HA (1999) Shrimp waste: chemical composition, nutritional value and utilization. Nahrung 43:418–23

INFOFISH (1991) Shrimp Waste Utilization , INFOFISH, technical handbook series 4, kualalampur, Malayasia

Kristinsson HG, Rasco BA (2000) Biochemical and functional properties of Atlantic salmon (Salmo salar) muscle hydrolyzed with various alkaline proteases. J Agric Food Chem 48:657–666

Lee YB, Eliot JG, Richansrud DA, Hugberg EC (1978) Predicting protein efficiency ratioby chemical determination of connective tissue content in meat. J Food Sci 43:1359–1362

Mizani M, Aminlari M, Khodabandeh M (2005) An effective method for producing a nutritive protein extract powder from shrimp-head waste. Sci Technol Int 11(1):2005

Morris SM (2005) Arginine metabolism in vascular biology and disease. Vasc Med 10:S83–S87

MPEDA (2009) Marine export review. Available from (www.mpeda.com ). 20th Oct 2009

Raghunath MR (1993) Enzymatic protein hydrolysate from tuna canning wastes standarisation of hydrolysis parameters. Fish Technol Soc 30(1):40–45

Rebeca B, Pena-Vera MI, Diaz-Castaneda M (1991) Production of fish protein hydrolysates with bacterial proteases: yield and nutritional value. J Food Sci 56:309–14

Shahidi F, Han XQ, Synowiecki J (1995) Production and characteristics of protein hydrolysates from capelin (Mallotus villosus). Food Chem 53:285–293

Synowiecki J, Alkhateeb N (2000) The recovery of protein hysrolysate during enzymatic isolation of chitin from shrimp Crangon crangon processing discards. Food Chem 68:147–152

Vidotti RM, Viegas EMM, Cariero DJ (2003) Amino acid composition of processed fish silage using different raw materials. Anim Feed Sci Technol 105:199–204

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dey, S.S., Dora, K.C. Optimization of the production of shrimp waste protein hydrolysate using microbial proteases adopting response surface methodology. J Food Sci Technol 51, 16–24 (2014). https://doi.org/10.1007/s13197-011-0455-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0455-4