Abstract

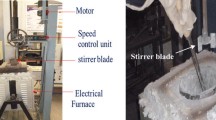

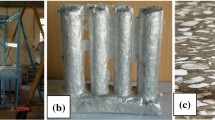

Mechanical properties and abrasive wear behaviour of functionally graded Al-Si12Cu/Al2O3 metal matrix composite fabricated under centrifugal casting technique was investigated and compared with unreinforced aluminium alloy. Hollow cylindrical component with dimensions 150 × 150 × 16 mm was produced under the centrifuging speed of 1200 rpm by incorporating 10 wt% Al2O3 particles of size 30–50 µm. The distribution of the Al2O3 reinforcement particles at outer, middle and inner surfaces in matrix was examined through the microstructural analysis. Hardness and tensile strength of the aluminium alloy and functionally graded composite were tested through microhardness tester and universal testing machine respectively. Abrasive wear of aluminium alloy and functionally graded composite was tested through dry abrasion tester for various loads and speeds on outer, middle and inner surfaces of composite specimens. Scanning electron microscopy analysis was carried out on the fractured tensile specimens and worn out specimens. The results revealed that particles were segregated more on the outer periphery and less on the inner periphery. The mechanical properties and the abrasive wear resistance of the functionally graded material were found higher than the unreinforced alloy. The wear rate was found to increase with increase in load, speed and for the distance from the outer periphery of the casting. The worn out surfaces revealed more cutting and ploughing as a result of three body abrasion wear caused by silica sand particles.

Similar content being viewed by others

References

Uyyuru R K, Surappa M K, and Brusethaug S, Tribol Int 40 (2007) 365.

Christy T V, Murugan N, and Kumar S, J Miner Mater Charact Eng 9(1) (2010) 57.

Singh L, Ram B, and Singh A, Int J Res Eng Technol 2(8) (2013) 375.

Gopi K R, Mohandas K N, Reddappa H N, and Ramesh M R, Int J Eng Adv Technol 2(5) (2013) 340.

Lozano D E, Mercado-Solis R D, Perez A J, Talamantes J, Morales F, and Hernandez Rodriguez M A L, Wear 267 (2009) 545.

Mishra AK, Sheokand R, and Srivastava R K, Int J Sci Res Publ 2(10) (2012) 1.

Uthayakumar M, Aravindan S, and Rajkumar K, Mater Des 47 (2013) 456.

Zhang J, Wang Y-Q, Zhou B-L, and Wu X-Q, J Mater Sci Lett 17, (1998) 1677.

Chen W, Wang Q, Zai C, Ma C, Zhu Y, and He W, J Mater Sci Lett 20 (2001) 823.

Gomes J R, Ramalho A, Gaspar M C, and Carvalho S F, Wear 259 (2005) 545.

Put S, Vleugels J, and Van der Biest O, J Mater Process Technol 143-144 (2003) 572.

Song C-J, Xu Z-M, and Li J-G, Compos Part A 38 (2007) 427.

Duque N B, Melgarejo Z H, and Suarez O M, Mater Charact 55 (2005) 167.

Derakhshesh M, Sina, H and Nazemi H, Majlesi J Mech Eng 4 (2011) 27.

Shivaji V. Gawali, and Vinod B. Tungikar, Sastech J 12 (2013) 15.

Rodriguez-Castro R, Wetherhold R C, Kelestemur M H, Mater Sci Eng A323 (2002) 445.

Leon-Patinon C A, Aguilar-Reyes E A, Bedolla-Becerril E, Bedolla-Jacuinde A, and Mendez-Diaz S, Wear 301 (2013) 688.

Su B, Yan H G, Chen J H, Zeng P L, Chen G, and Chen C C, J Mater Eng Perform 22 (2013) 1355.

Humberto Melgarejo Z, Marcelo Suarez O, Sridharan, K (2008) Compos Part A 39 1150.

Vieira A C, Sequeira P D, Gomes J R, and Rocha L A, Wear 267 (2009) 585.

Barekar N, Tzamtzis S, Dhindaw B K, Patel J, Hari Babu N, and Fan Z, J Mater Eng Perform (2009).

Liu Q, Ke L, Liu F, Huang C, and Xing L, Mater Des 45 (2013) 343.

Lin C Y, Bathias C, Mc Shane H B, and Rawlings R D, Powder Metall. 42 (1999) 29.

Askari E, Mehrali M, Metselaar I H S C, Kadri N A, and Rahman Md M, J Mech Behav Biomed Mater 12 (2012) 144.

Radhika N, and Raghu R, J Tribol 137(3) (2015) 1.

Kok M, and Ozdin K, J Mater Process Technol 183 (2007) 301.

Kumar S, and Balasubramanian V, Tribol Int 43 (2010) 414.

Agarwal G, Patnaik A, and Sharma R K, Int J Eng Res Appl 2 (2012) 1148.

Rajan T P D, Jayakumar E, and Pai B C, Trans Indian Inst Met 65 (6) (2012) 531.

Acknowledgments

Sincere thanks to the Department of Science and Technology for the fund support (Grant No. SR/S3/MERC/0116/2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Radhika, N. Mechanical Properties and Abrasive Wear Behaviour of Functionally Graded Al-Si12Cu/Al2O3 Metal Matrix Composite. Trans Indian Inst Met 70, 145–157 (2017). https://doi.org/10.1007/s12666-016-0870-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0870-3