Abstract

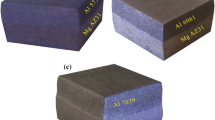

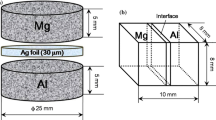

Aluminum and magnesium were joined through diffusion bonding using Ni interlayer. The microstructure and mechanical performance of the Al/Ni/Mg joints at different temperatures was investigated by means of scanning electron microscope (SEM), electro-probe microanalyzer (EPMA), X-ray diffraction (XRD), Vickers hardness testing, and shear testing. The results show that the addition of Ni interlayer eliminates the formation of Mg–Al intermetallic compounds and improves the bonding strength of the Al/Mg joints. The Al/Ni/Mg joints are formed by the diffusion of Al, Ni and Mg, Ni. The microstructure at the joint interface from Al side to Mg side is Al substrate/Al–Ni reaction layer/Ni interlayer/Mg–Ni reaction layer/Mg substrate multilayer structure. The microhardness of the Mg–Ni reaction layer has the largest value of HV 255.0 owing to the existence of Mg2Ni phase. With the increase of bonding temperature, the shear strength of the joints increases firstly and then decreases. The Al/Ni/Mg joint bonds at 713 K for 90 min, exhibiting the maximum shear strength of 20.5 MPa, which is greater than that of bonding joint bonded directly or with Ag interlayer. The fracture of the joints takes place at the Mg–Ni interface rather than the Al–Ni interface, and the fracture way of the joints is brittle fracture.

Similar content being viewed by others

References

Eslami P, Taheri AK. An investigation on diffusion bonding of aluminum to copper using equal channel angular extrusion process. Mater Lett. 2011;65(2):1862.

Zhang JX, Zhang KL, Liu YT, Zhong L. Microstructure and texture evolution of 6016 aluminum alloy during hot compressing deformation. Rare Met. 2014;33(4):404.

Yang SY, Zhong HR, Tao YS, Yang Y. Microstructure and properties of friction stir welded joints of magnesium rare earth alloy. Chinese J Rare Met. 2011;37(1):33.

Chio D, Ahn B, Lee C, Yeon Y, Song K, Jung S. Formation of intermetallic compounds in Al and Mg alloy interface during friction stir spot welding. Intermetallics. 2011;19(2):125.

Hayat F. The effects of the welding current on heat input, nugget geometry, and the mechanical and fractural properties of resistance spot welding on Mg/Al dissimilar materials. Mater Des. 2011;32(4):2476.

Dietrich D, Nickel D, Krause M, Lampke T, Coleman MP, Randle V. Formation of intermetallic phases in diffusion-welded joints of aluminum and magnesium alloys. J Mater Sci. 2011;46(2):357.

Liu P, Li YJ, Geng HR, Wang J. A study of phase constitution near the interface of Mg/Al vacuum diffusion bonding. Mater Lett. 2005;59(16):2001.

Liu LM, Liu XJ, Liu SH. Microstructure of laser-TIG hybrid welds of dissimilar Mg alloy and Al alloy with Ce as interlayer. Scr Mater. 2006;55(4):383.

Zhao LM, Zhang ZD. Effect of Zn alloy interlayer on interface microstructure and shear strength of diffusion-bonded Mg–Al joints. Scr Mater. 2008;58(4):283.

Gao M, Mei SW, Li XY, Zeng XY. Characterization and formation mechanism of laser-welded Mg and Al alloys using Ti interlayer. Scr Mater. 2012;67(2):193.

Qi XD, Liu LM. Fusion welding of Fe-added lap joints between AZ31B magnesium alloy and 6061 aluminum alloy by hybrid laser-tungsten inert gas welding technique. Mater Des. 2012;33(2):436.

Shang J, Wang KH, Qi Z, Zhang DK, Huang J, Li GL. Microstructure characteristics and mechanical properties of cold metal transfer welding Mg/Al dissimilar metals. Mater Des. 2012;34(3):559.

Wu K, Chang H, Maawad E, Gan WM. Microstructure and mechanical mechanism properties of the Mg/Al laminated composite fabricated by accumulative roll bonding (ARB). Mater Sci Eng, A. 2010;527(13–14):3073.

Sabetghadam H, Hanzaki AZ, Araee A, Hadian A. Microstructural evaluation of 410SS/Cu diffusion-bonded joint. J Mater Sci Technol. 2010;26(2):163.

Wang YY, Luo GQ, Zhang J, Shen Q, Zhang LM. Effect of silver interlayer on microstructure and mechanical properties of diffusion-bonded Mg-Al joints. J Alloy Compd. 2012;541(2):458.

He P, Feng JC, Qian YY. A new model of interfacial physical contact in diffusion bonding. J Mater Sci Technol. 2004;20(1):109.

Santella ML, Horton JA, David SA. Welding behavior and microstructure of an Ni3Al. Weld J. 1988;64(1):63.

Elthalabawy W, Khan T. Liquid phase bonding of 316L stainless steel to AZ31 magnesium alloy. J Mater Sci Technol. 2011;27(1):22.

Luo GQ, Zhang J, Li MJ, Wei QQ, Shen Q, Zhang LM. Interfacial microstructure and mechanical strength of 93W/Ta diffusion bonded joints with Ni interlayer. Metall Mater Trans A. 2013;44(2):602.

Zhang J, Luo GQ, Wang YY, Xiao Y, Shen Q, Zhang LM. Effect of Al thin film and Ni foil interlayer on diffusion bonded Mg-Al dissimilar joints. J Alloys Compd. 2013;556(1):139.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51202175) and the Program for Institutions of Higher Learning Discipline Innovation Conference (111 Project) (No.B13035).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Luo, GQ., Shen, Q. et al. Characterization of diffusion-bonded joint between Al and Mg using a Ni interlayer. Rare Met. 35, 537–542 (2016). https://doi.org/10.1007/s12598-014-0394-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0394-0