Abstract

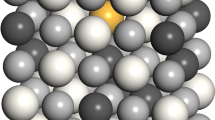

Gradient cemented carbide is usually employed as the substrate for coated carbide insert. In this work, gradient cemented carbide with ultrafine Ti(C0.5,N0.5) was prepared and its microstructure and properties were researched. Moreover, this novel substrate was coated to investigate cutting performance. It is found that the average WC grain size in the gradient zone is larger than that in the bulk. Owing to ultrafine Ti(C0.5,N0.5) introduction, gradient cemented carbide prepared by vacuum sintering exhibits full densification. By contrast, the gradient cemented carbide with ultrafine Ti(C0.5,N0.5) shows higher transverse rupture strength (TRS) and hardness than the homogenous one. Gradient cemented carbide suffers small TRS reduction after coating, and the bonding between coatings and gradient substrate is tidy and compact. The coated gradient cemented carbide shows much better endurance and impact resistance than the coated homogenous one. It confirms the superiority of gradient cemented carbide when used as the substrate for coating inserts.

Similar content being viewed by others

References

Guo ZX, Xiong J, Yang M, Bi SQ. Adherent Ti(C,N) coatings on cemented carbide substrates with Fe/Ni/Co binder. Metall Mater Trans B. 2009;40(6):871.

Suzuki H, Hayashi K, Taniguchi Y. The beta-free layer formed near the surface of vacuum-sintered WC-beta-Co alloys containing nitrogen. Trans Jpn Inst Metals. 1981;22(11):758.

Schwarzkopf M, Exner HE, Fischmeister HF, Schintlmeister. Kinetics of compositional modification of (W, Ti)C–WC–Co alloy surfaces. Mater Sci Eng A. 1988;105-106(Part 1):225.

Gustafson P, Östlund A. Binder-phase enrichment by dissolution of cubic carbides. Int J Refract Met Hard Mater. 1994;12(3):129.

Ekroth M, Frykholm R, Lindholm M, Andrén H-O, Ågren J. Gradient zones in WC–Ti(C,N)-based cemented carbides: experimental study and computer simulations. Acta Mater. 2000;48(9):2177.

Frykholm R, Jansson B, Andrén H-O. The influence of carbon content on formation of carbo-nitride free surface layers in cemented carbides. Int J Refract Met Hard Mater. 2002;20(5–6):345.

Lengauer W. Diffusional control of the near-surface microstructure in functional gradient hardmetals. Mat.-wiss.u.Werkstofftech. 2005;36(10):460.

Zhang WZ, Liu Y, He YH, Wang HB. Effect of Ti(CN) content on the gradient structure and properties of cemented carbides. Rare Met Cem Carbides. 2005;33(2):28.

Chen LM, Lengauer W, Dreyer K. Advances in modern nitrogen-containing hardmetals and cermets. Int J Refract Met Hard Mater. 2000;18(2–3):153.

Shao YF, Yang X, Zhao X, Wang SQ. Brittle-ductile behavior of a nanocrack in nanocrystalline Ni: a quasicontinuum study. Chin Phys B. 2012;21(9):093104.

Guo YQ, Huang R, Song J, Wang X, Song C, Zhang YX. Growth characteristics of amorphous-layer-free nanocrystalline silicon films fabricated by very high frequency PECVD at 250 °C. Chin Phys B. 2012;21(6):065201.

Chen L, Wu EX, Yin F, Li J. Effects of gradient structure on the microstructures and properties of coated cemented carbides. J Univ Sci Technol Beijing. 2006;13(4):363.

Yin F, Chen KH, Wang SQ. Influences of functionally graded structure of substrate on performance of coated cemented carbide. J Cent South Univ. 2005;36(5):776.

Liu Y, Wang HB, Long ZY, Yang JG, Zhang WZ. Enhancement on the transverse fracture strength of functional graded structure cemented carbides. J Mater Sci. 2005;40(20):5525.

Chen LM, Lengauer W, Ettmayer P. Fundamentals of liquid phase sintering for modern cermets and functionally graded cemented carbides (FGCC). Int J Refract Met Hard Mater. 2000;18(6):307.

Frykholm R, Ekroth M, Jansson B, Andrén H-O, Ågren J. Effect of cubic phase composition on gradient zone formation in cemented carbides. Int J Refract Met Hard Mater. 2001;19(4–6):527.

Wang Q, Wang WZ, Zhang HX, Li GH. Growth kinetics of cermet particles in the form of dissolve-separation. J Northeast Univ. 1996;17(5):490.

Westphal H, Sottke V, Tabersky R, van den Berg H, KÖnig U, New hard coatings on the basis of carbonitrides of titanium and zirconium. In: Proceedings of 14th international Plansee seminar, Reutte, 1997, 55.

Liu N, Xu YD, Li H, Chen MH, Zhou J, Xie F, Yang HD. Cutting and wearing characteristics of TiC-based cermets cutters with nano-TiN addition. J Mater Process Technol. 2005;161(3):478.

Manoj Kumar BV, Basu B. Mechanisms of material removal during high temperature fretting of TiCN–Ni based cermets. Int J Refract Met Hard Mater. 2008;26(6):504.

Manoj Kumar BV, Kumar RJ, Basu B. Crater wear mechanisms of TiCN–Ni–WC cermets during dry machining. Int J Refract Met Hard Mater. 2007;25(5–6):392.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51074110), Research Funds for the Central Universities (No. 2011SCU11038), and the Chengdu Science and Technology Project (Nos. 10GGZD080GX-268 and 11DXYB096JH-027). Chengdu Mingwu Science & Technology Co., Ltd. of China is thanked for facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, TE., Sun, L., Xiong, J. et al. Adherent coating on gradient cemented carbide with ultrafine Ti(C0.5,N0.5). Rare Met. 34, 413–420 (2015). https://doi.org/10.1007/s12598-013-0213-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0213-z