Abstract

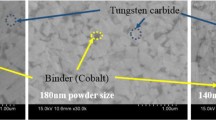

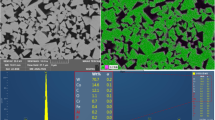

The aim of this study is to optimize micro-mills and their conditions of use to manufacture plastic injection molds in hardened tool steels by micro-milling. The presented results deal with the test of four types of tungsten carbide square end micro-mills in elementary operations with different feed rates and cutting speeds in order to analyze the evolution of cutting forces, cutting stability, tool life, tool wear, surface roughness and burs formation. This experimental approach allows highlighting the influence of cutting conditions, especially feed rate, on burr formation and tool life. This analysis shows a correlation between the micro-mills characteristics (geometry, composition of tungsten carbide) and their wear behavior. Moreover, some dynamic aspects of the micro-milling process are underlined through the influence of cutting speed on cutting stability. This type of experimental study is suitable for the optimization of the tool edge geometry and it reveals the need to develop a predictive model adapted to micro-milling to optimize the dynamic behavior of the tool.

Similar content being viewed by others

References

Masuzawa, T. and Tonshoff, H. K., “Three-dimensional micromachining by machine tools,” Annals of the CIRP, Vol. 46, pp. 621–628, 1997.

Friedrich, C. R., Coane, P. J., and Vasile, M. J., “Micromilling development and applications for microfabrication,” Microelectronic Engineering, Vol. 35, pp. 367–372, 1997.

Bissacco, G., Hansen, H. N., and De Chiffre, L., “Micromilling of hardened tool steel for mould making applications,” Journal of Materials Processing Technology, Vol. 167, pp. 201–207, 2005.

Graf, V. D., Schulenburg, M., and Uhlmann, E., “Scaling Effects in Milling Operations of Tungsten-Copper-Composites,” Proc. of the International Conference on Mechanical and Manufacturing Engineering, 2008.

Simoneau, A., Ng, E., and Elbestawi, M. A., “Chip formation during micro scale cutting of a medium carbon steel,” International Journal of Machining Tools and Manufacture, Vol. 46, pp. 467–481, 2006.

Bissacco, G., Hansen, H. N., and Slunsky, J., “Modeling the cutting edge radius size effect for force prediction in micro milling,” Annals of the CIRP, Vol. 57, pp. 113–116, 2008.

Lucca, D. A., Rhorer, R. L., and Komanduri, R., “Energy dissipation in the ultraprecision machining of copper,” Annals of the CIRP, Vol. 40, pp. 69–72, 1991.

Komanduri, R., “Some aspects of machining with negative rake tools simulating grinding,” International Journal of Machine Tool Design, Vol. 11, pp. 223–233, 1971.

Fang, F. Z. and Liu, Y. C., “On minimum exit-burr in micro cutting,” Journal of Micromechanics and Micro Engineering, Vol. 14, pp. 984–988, 2004.

Aramcharoen, A., Mativvenga, P. T., Yang, S., Cooke, K. E., and Teer, D. G., “Evaluation and selection of hard coating for micro milling of hardened tool steel,” International Journal of Machine Tools and Manufacture, Vol. 48, pp. 1578–1584, 2008.

Bao, W. Y. and Tansel, I. N., “Modeling micro-end-milling operations. Part III: influence of tool wear,” International Journal of Machine Tools and Manufacture, Vol. 40, pp. 2193–2211, 2000.

Raju, K., Janardhana, G., Kumar, P., and Rao, V., “Optimization of cutting conditions for surface roughness in CNC end milling,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 3, pp. 383–391, 2011.

Kopac, J., Sokovic, M., and Dolinsek, S., “Tribology of coated tools in conventional and HSC machining,” Journal of Materials Processing Technology, Vol. 118, pp. 377–384, 2001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gilbin, A., Fontaine, M., Michel, G. et al. Capability of tungsten carbide micro-mills to machine hardened tool steel. Int. J. Precis. Eng. Manuf. 14, 23–28 (2013). https://doi.org/10.1007/s12541-013-0004-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0004-3