Abstract

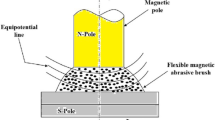

Self-sharpening effect creates good abrasive performance in magnetic abrasive finishing (MAF); however, abrasive is easily flown away by the centrifugal force, reducing the finishing efficiency in MAF. Therefore, a novel polishing effect of flexible self-sharpening was demonstrated to reveal the excellent abilities in magnetic finishing with abrasive gel (MFGA), and grey relational method based on Taguchi experimental data was applied to obtain the optimal parameters in MFGA. In this paper, a cylindrical rod was finished with silicone gel to compare the MR and SR to those without this medium, and showed the flexible self-sharpening effect in MFGA. The results displayed that high temperature of the gel abrasive (exceeded 110°C) during polishing effect induced slow motion of the gel in the working area; hence, old abrasives would be pushed outside the working area during the motion of workpiece and flow motion of gel would pull the new abrasives into the polishing area, creating flexible self-sharpening effect in MFGA. Furthermore, from the grey relational analysis, the best experimental combination of the influential factors was presented; additionally, based on the analysis of variance, concentration of steel grit, machining time and kinds of abrasive dominate the behaviors of MFGA process.

Similar content being viewed by others

Abbreviations

- x * i (k):

-

the sequence after data pre-processing

- max s (o) i (k):

-

the largest value of x (o) i (k)

- min x (o) i (k):

-

the smallest value of x (o) i (k)

- S m :

-

sum of squares, based on the mean

- L :

-

total experimental runs (L = 18 in this paper)

- S T :

-

sum of squares, based on the total variation

- S P :

-

sum of squares, based on machining parameters P

- S E :

-

sum of squares, based on the error

- y oi :

-

value of y 0 in the i th experiment (i = 1 to 18 in this paper)

- y 0Pi :

-

sum of the i th level of machining parameters P (i = 1, 2 or i = 1, 2, 3)

- N:

-

repeated number of each level of machining parameters P

- f P :

-

number of degrees of freedom of parameter P

- V P :

-

variance of parameter P

- V P :

-

sum of variance

- C P :

-

contribution of degree of parameter P

- V e :

-

estimated value for the prediction of the grey relational grade

- \(\overline V _m \) :

-

mean value of total grey relational grades

- V i :

-

the value of the grey relational grade at optimal level

- n :

-

the number of machining parameters with C p greater than 20%

References

Chang, G. W., Yan, B. H. and Hsu, R. T., “Study on cylindrical magnetic abrasive finishing using unbonded magnetic abrasives,” International Journal of Machine Tools & Manufacture, Vol. 42, No. 5, pp. 575–583, 2002.

Jayswal, S. C., Jain, V. K. and Dixit, P. M., “Modeling and simulation of magnetic abrasive finishing process,” International Journal of Advanced Manufacturing Technology, Vol. 26, No. 5–6, pp. 477–490, 2005.

Wang, A. C. and Lee, S. J., “Study the characteristics of magnetic finishing with gel abrasive,” International Journal of Machine Tools & Manufacture, Vol. 49, No. 14, pp. 1063–1069, 2009.

Kim, J. D. and Choi, M. S., “Study on magnetic polishing of free-form surface,” International Journal of Machine Tools & Manufacture, Vol. 37, No. 8, pp. 1179–1187, 1997.

Yan, B. H., Chang, G. W., Chang, J. H. and Hsu, R. T., “Improving Electrical Discharge Machined Surfaces Using Magnetic Abrasive Finishing,” Machining Science & Technology, Vol. 8, No. 1, pp. 103–118, 2004.

Yin, S. and Shinmura, T., “Vertical vibration-assisted magnetic abrasive finishing and deburring for magnesium alloy,” International Journal of Machine Tools & Manufacture, Vol. 44, No. 12–13, pp. 1297–1303, 2004.

Kim, T. W. and Kwak, J. S., “A study on deburring of magnesium alloy plate by magnetic abrasive polishing,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 2, pp. 189–194, 2010.

Mun, S. D., “Micro machining of high-hardness materials using magnetic abrasive grains,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 5, pp. 763–770, 2010.

Singh, D. K., Jain, V. K. and Raghuram, V., “Parametric study of magnetic abrasive finishing process,” Journal of Materials Processing Technology, Vol. 149, No. 1–3, pp. 22–29, 2004.

Lin, C. T., Yang, L. D. and Chow, H. M., “Study of magnetic abrasive finishing in free-form surface operations using the Taguchi method,” International Journal of Advanced Manufacturing Technology, Vol. 34, No. 1–2, pp. 122–130, 2007.

Lin, Y. C. and Lee, H. S., “Optimization of machining parameters using magnetic-force-assisted EDM based on gray relational analysis,” International Journal of Advanced Manufacturing Technology, Vol. 42, No. 11–12, pp. 1052–1064, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, L., Wang, AC., Chou, SH. et al. Investigating of flexible self-sharpening and optimal parameters in magnetic finishing with gel abrasive. Int. J. Precis. Eng. Manuf. 13, 655–661 (2012). https://doi.org/10.1007/s12541-012-0085-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0085-4