Abstract

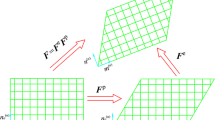

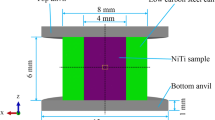

Crystal plasticity finite element method based on a representative volume element model, which includes the effect of grain shape and size, is combined with electron backscattered diffraction experiment in order to investigate plastic deformation of NiTi shape memory alloy during uniaxial compression at 400 °C. Simulation results indicate that the constructed representation of the polycrystal microstructure is able to effectively simulate macroscopically global stress-strain response and microscopically inhomogeneous microstructure evolution in the case of various loading directions. According to slip activity and Schmid factor in {110}<100>, {010}<100> and {110}<111> slip modes, <100> slip modes are found to play a dominant role in plastic deformation, while <111> slip mode is found to be a secondary slip mode. In addition, the simulation results are supported well by the experimental ones. With the progression of plastic deformation, the (001) [\(0\bar 10\)] texture component gradually disappears, while the γ-fiber (<111>) texture is increasingly enhanced.

Similar content being viewed by others

References

O. Benafan, R. Noebe, S. Padula, A. Garg, B. Clausen, R. Vaidyanathan, et al. Int. J. Plasticity 51, 103 (2013).

A. Isalgue, C. Auguet, R. Grau, V. Torra, N. Cinca, and J. Fernandez, J. Mater. Eng. Perform. 24, 3323 (2015).

Y. Liu, Acta Mater. 95, 411 (2015).

E. Twohig, P. Tiernan, J. Butler, C. Dickinson, and S. Tofail, Acta Mater. 68, 140 (2014).

H. M. Paranjape, S. Manchiraju, and P. M. Anderson, Int. J. Plasticity 80, 1 (2016).

F. Weafer, Y. Guo, and M. Bruzzi, J. Mech. Behav. Biomed. 53, 210 (2016).

L. Hu, S. Jiang, Y. Zhang, Y. Zhao, S. Liu, and C. Zhao, Intermetallics 70, 45 (2016).

K. M. Armattoe, M. Haboussi, and T. B. Zineb, Int. J. Solids Struct. 51, 1208 (2014).

S. Haroush, E. Priel, D. Moreno, A. Busiba, I. Silverman, Y. Gelbstein, et al. Mater. Design 83, 75 (2015).

M. Ardeljan, I. J. Beyerlein, B. A. McWilliams, and M. Knezevic, Int. J. Plasticity 83, 90 (2016).

L. Li, L. Shen, G. Proust, C. K. Moy, and G. Ranzi, Mat. Sci. Eng. A 579, 41 (2013).

H. Sheikh, R. Ebrahimi, and E. Bagherpour, Mater. Design 109, 289 (2016).

S. Manchiraju and P. M. Anderson, Int. J. Plasticity 26, 1508 (2010).

L. Qiao and R. Radovitzky, J. Mech. Phys. Solids. 93, 93 (2016).

C. Yu, G. Kang, and Q. Kan, J. Mech. Phys. Solids. 82, 97 (2015).

R. Hill and J. Rice, J. Mech. Phys. Solids. 20, 401 (1972).

Y. Huang, A User-Material Subroutine Incroporating Single Crystal Plasticity in the ABAQUS Finite Element Program, pp. 1–21, Harvard University, USA (1991).

D. Peirce, R. Asaro, and A. Needleman, Acta Metall. 30, 1087 (1982).

H. Abdolvand, M. R. Daymond, and C. Mareau, Int. J. Plasticity 27, 1721 (2011).

S.-Y. Jiang, Y.-Q. Zhang, Y.-N. Zhao, M. Tang, and W.-L. Yi, J. Cent. South Univ. 20, 24 (2013).

R. J. Asaro, Adv. Appl. Mech. 23, 1 (1983).

L. Lv and L. Zhen, Mat. Sci. Eng. A 528, 6673 (2011).

O. Diard, S. Leclercq, G. Rousselier, and G. Cailletaud, Int. J. Plasticity 21, 691 (2005).

P. Van Houtte, L. Delannay, and S. Kalidindi, Int. J. Plasticity 18, 359 (2002).

L.-T. Li, Y. Lin, L. Li, L.-M. Shen, and D.-X. Wen, J. Mater. Eng. Perform. 24, 1294 (2015).

K.-S. Zhang, J. W. Ju, Z. Li, Y.-L. Bai, and W. Brocks, Mech. Mater. 85, 16 (2015).

J. Segurado and J. Llorca, Comp. Mater. Sci. 76, 3 (2013).

R. Quey, P. Dawson, and F. Barbe, Comput. Method. Appl. M. 200, 1729 (2011).

T. Erinosho, D. Collins, A. Wilkinson, R. Todd, and F. Dunne, Int. J. Plasticity 83, 1 (2016).

M.-G. Lee, J. Wang, and P. M. Anderson, Mat. Sci. Eng. A 463, 263 (2007).

M. Knezevic, I. J. Beyerlein, M. L. Lovato, C. N. Tomé, A. W. Richards, and R. J. McCabe, Int. J. Plasticity 62, 93 (2014).

J. Wert, Q. Liu, and N. Hansen, Acta Mater. 45, 2565 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, L., Jiang, S., Zhang, Y. et al. Crystal plasticity finite element simulation of NiTi shape memory alloy based on representative volume element. Met. Mater. Int. 23, 1075–1086 (2017). https://doi.org/10.1007/s12540-017-7118-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-7118-6