Abstract

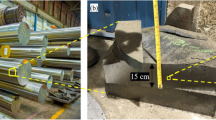

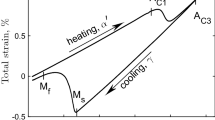

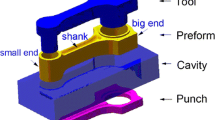

Oxides Dispersed strengthened (ODS) stainless steels are foreseen for fuel cladding tubes in the coming generation of fission nuclear reactors. In spite of a ferritic matrix those steels present a convenient creep behavior thanks to very fine oxides dispersion. Those grades are currently obtained by Powder Metallurgy (PM). After mechanical alloying with the oxide, the powder is commonly consolidated by Hot Isostatic Pressing (HIP) or Hot Extrusion (HE). The control of microstructure after extrusion is a key issue for this grade regarding service conditions. On CEA facilities, new ferritic ODS stainless steels are produced by HE. In order to explain the microstructure observed at various places on an interrupted extrusion samples the thermo-mechanical history applied to the material must be determined. In this paper we use the Finite Element Method to simulate the co-extrusion of a PM grade in a soft steel can. The PM steel grade behavior law is determined on a fully dense material by hot torsion tests, taking into account temperature and strain-rate sensitivity. Thus strain and thermal history are computed for material points lying on various flow lines during extrusion.

Similar content being viewed by others

References

de Carlan Y, Bechade J-L et al (2009) CEA developments of new ferritic ODS alloys for nuclear applications. J Nucl Mater 386–388:430–432

Ukai S, Hatakeyama K et al (2002) Consolidation process study of 9Cr-ODS martensitic steels. J Nucl Mater I. 307-311:758–762

Steckmeyer A, Praud M, Fournier B, Malaplate J, Garnier J, Béchade JL, Tournié I, Tancray A, Bougault A, Bonnaillie P (2010) Tensile properties and deformation mechanisms of a 14Cr ODS ferritic steel. J Nucl Mater 405(2):95–100

Hoelzer DT, Bentley J, Sokolov MA, Miller MK, Odette GR, Alinger MJ (2007) Influence of particle dispersions on the high-temperature strength of ferritic alloys. J Nucl Mater 367-370(Part 1):166–172

Alamo A, Lambard V, Averty X, Mathon MH (2004) Assessment of ODS-14%Cr ferritic alloy for high temperature applications. J Nucl Mater 329-333(Part 1):333–337

Auger MA, Leguey T, Muñoz A, Monge MA (2011) Microstructure and mechanical properties of ultrafine-grained Fe-14Cr and ODS Fe-14Cr model alloys. J Nucl Mater 417:213–216

Dou P, Kimura A, Okuda T, Inoue M (2011) Effect of extrusion temperature on the Nano-mesoscopic structure and mechanical properties of an Al-alloyed High-Cr ODS ferritic steel. J Nucl Mater 417(1–3):166–170

Miller MK, Russell KF, Hoelzer DT (2006) Characterisation of precipitates in MA/ODS ferritic alloys. J Nucl Mater 351:261–268

Olier P, Malaplate J, Mathon MH, Nunes D, Hamon D, Toualbi L, de Carlan Y, Chaffron L (2012) Chemical and microstructural evolution on ODS Fe-14CrWTi steel during manufacturing stages. J Nucl Mater 428(1-3):40–46. doi:10.1016/j.jnucmat.2011.10.042

Praud M, Mopiou F, Malaplate J (2010) Plasticity of nano-strengthened steels. Nucl Mater Conf NuMAt 2010

Baccino R, Moret F (2000) Numerical modeling of powder metallurgy processes. Mater Des 21(4):359–364. doi:10.1016/S0261-3069(99)00094-1

Ratti M, Leuvrey D, Mathon MH, De Carlan Y (2009) Influence of titanium on nano-cluster (Y, Ti, O) stability in ODS ferritic materials. J Nucl Mater 386–388:540–543

Sornin D, Grosdidier T, Malaplate J, Tiba I, Bonnaillie P, Allain-Bonasso N, Nunes D (2013) Microstructural study of an ODS stainless steel obtained by hot uni-axial pressing. J Nucl Mater 439:19–24

Fields DS, Backofen WA (1979) Determination of strain hardening characteristics by TorsionTesting. Proc ASTM 57:583–591

Sung-Il K, Yeon-Chul Y (2002) Continuous dynamic recrystallization of AISI 430 ferritic stainless steel. Met Mater Int 8(1):7–13

Praud M (2012) Plasticité d’alliages renforcés par nano-précipitation Université Toulouse 3 Paul Sabatier

Kim SI, Lee Y, Byon SM (2003) Study on constitutive relation of AISI 4140 steel subject to large strain at elevated temperatures. J Mater Process Technol 1-3:84–89. doi:10.1016/S0924-0136(03)00742-8

Kajberg J, Sundin KG (2013) Material characterisation using high-temperature Split Hopkinson pressure bar. J Mater Process Technol 213(4):522–531. doi:10.1016/j.jmatprotec.2012.11.008

Bao Y, Wierzbicki T (2005) On the cut-off value of negative triaxiality for fracture. Eng Fract Mech 72(7):1049–1069

Acknowledgments

This work has been supported by the Nuclear Energy Direction of CEA, AREVA and EDF in the context of MACNA framework agreement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sornin, D., Karch, A. & Nunes, D. Finite element method simulation of the hot extrusion of a powder metallurgy stainless steel grade. Int J Mater Form 8, 145–155 (2015). https://doi.org/10.1007/s12289-013-1156-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-013-1156-5