Abstract

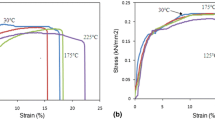

In this paper, the main parameters for the process design of thermo active deep drawing processes with metastable steels are specified. As a consequence of the strain- and temperature-dependent martensitic phase transformation, the CrNi-steels have a very complex forming and failure behavior. Particularly, the strong heating of the blank, induced by the hardening increase, influences the yield properties, the failure and the tribological system. Hence, a robust process design with FEM is subordinated to the correct virtual description of these process parameters. Both, experimental methods for an accurate measurement of the forming, friction and failure properties, as well as numerical models were introduced in this study. Using these models, temperature dependent parameters like phase transformation from γ-austenite to α′-martensite, yield properties, failure or friction can be easily included into the virtual process modeling. The model was successfully validated by biaxial stretching tests and rectangular cups, drawn at different tool temperatures.

Similar content being viewed by others

References

Krauer J, Hora P (2009) Thermoactive process modelling of deep drawing with austenitic stainless steels. Proceedings of the IDDRG’09, pp 17–28

Nakazima K, Kikuma T, Hasuka K (1968) Study on the formability of steel sheets. Yawata Technical Report No. 264, pp 141–154

ISO/DIS 12004–2 (2006) Metallic materials – Sheet and strip – Determination of forming limit curves – Part 2: Determination of forming limit curves in laboratory

Volk W (2006) New experimental and numerical approach in the evaluation of the FLD with the FE-method. Proceedings of the FLC Zurich, pp 26–30

Eberle B, Volk W, Hora P (2008) Automatic approach in the evaluation of the FLD-curve. Proceedings of the Numisheet’08, pp 279–284

Hora P, Eberle B, Volk W (2009) Numerical methods for a robust user-independent evaluation of Nakajima tests for the FLC determination. Proceedings of the IDDRG’09, pp 437–448

Hänsel A (1998) Nichtisothermes Werkstoffmodell für die FE-Simulation von Blechumform-prozessen mit metastabilen austenitischen CrNi-Stählen, PhD-Thesis ETH Nr. 12672, Fortschr.-Ber. VDI Reihe 2 Nr. 491, VDI Verlag

Ramirez JAC, Tsuta T, Mitani Y, Osakada K (1992) Flow stress and phase transformation analyses in the austenitic stainless steel under cold working (Part 1, phase transformation characteristics and constitutive formulation by energetic criterion). JSME Int J Series I 35(2):201–209

Tsuta T, Cortes JA (1993) Flow stress and phase transformation analyses in the austenitic stainless steel under cold working (Part 2, incremental theory under multiaxial stress state by the finite-element method). JSME Int J Series A 36(1):63–72

Olson GB, Cohen M (1975) Kinetics of strain-induced martensitic nucleation. Metall Trans A 6A:791–795

Hora P, Tong L, Reissner J (2003) Mathematical prediction of FLC using macroscopic instability criteria combined with micro structural crack propagation models. Proceedings of the Plasticity’03

Hora P, Tong L (2008) Theoretical prediction of the influence of curvature and thickness on the FLC by the enhanced modified maximum force criterion. Proceedings of the Numisheet’08, pp 205–210

Hora P, Volk W, Roll K, Griesbach B, Kessler L, Hotz W (2008) Benchmark 1 – virtual forming limit curves. Proceedings of the Numisheet’08 – Part B

Hora P, Tong L (1994) Prediction methods for ductile sheet metal failure using FE-simulation. Proceedings of the IDDRG’94

Hora P, Tong L, Reissner J (1996) A prediction method for ductile sheet metal failure. Proceedings of the Numisheet’96

Krauer J, Hora P, Tong L, Berisha B (2007) Forming limit prediction of metastable materials with temperature and strain induced martensite transformation. Proceedings of the Numiform’07, pp 1263–1268

Krauer J, Hora P, Tong L (2008) Temperature dependent forming limit prediction for metastable stainless. Proceedings of the Numisheet’08, pp 235–240

Vogel H (1921) The temperature dependence law of the viscosity of fluids. Physikalische Zeitschrift 22:645–646

Grüebler R, Hora P (2009) Temperature and velocity dependent friction modelling for sheet metal forming. Int J Mater Form, Supplement, pp 251–254

Krauer J (2010) Erweiterte Werkstoffmodelle zur Beschreibung des thermischen Umformverhaltens metastabiler Stähle, PhD-Thesis ETH Nr. 19070, Fortschr.-Ber. VDI Reihe 2 Nr. 676, VDI Verlag

Acknowledgements

The authors are very grateful to CTI, the Innovation Promotion Agency of Switzerland, for financial support of this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krauer, J., Hora, P. Enhanced material models for the process design of the temperature dependent forming behavior of metastable steels. Int J Mater Form 5, 361–370 (2012). https://doi.org/10.1007/s12289-011-1057-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-011-1057-4